Dek . 15, 2024 08:16 Back to list

EPDM Gaskets for Automotive Fuel Tanks and Their Critical Role in Sealing Solutions

The Role of EPDM in Automotive Fuel Tank Gaskets

Ethylene Propylene Diene Monomer (EPDM) is a type of synthetic rubber that has found widespread application in the automotive industry, particularly in fuel tank gaskets. Its unique properties make it an ideal material for ensuring the integrity and longevity of fuel systems. In this article, we will explore the benefits of using EPDM for automotive fuel tank gaskets, its manufacturing process, and its significance in enhancing vehicle performance and safety.

Understanding EPDM

EPDM is a terpolymer that consists of ethylene, propylene, and a diene component. This composition endows EPDM with several advantageous properties, including excellent weather resistance, UV stability, and a remarkable ability to withstand a wide range of temperatures. Furthermore, EPDM is known for its resistance to ozone and various chemicals, which is particularly important given the harsh environments that automotive parts often face.

Importance of Gaskets in Fuel Tanks

Gaskets play a crucial role in automotive fuel tanks. They are designed to create a tight seal between the fuel tank and its components, preventing fuel leaks and ensuring that the tank maintains proper pressure. A malfunctioning gasket can lead to fuel evaporation, which not only wastes fuel but also poses significant safety hazards due to the risk of fire or explosion. Therefore, choosing the right material for gaskets is essential in maintaining both vehicle efficiency and safety.

EPDM's Properties for Fuel Tank Gaskets

1. Chemical Resistance One of the most significant advantages of EPDM is its resistance to various chemicals, including gasoline and diesel fuels. This property helps ensure that the gasket remains intact and functional over time, preventing leaks and maintaining fuel integrity.

2. Temperature Tolerance EPDM gaskets can withstand extreme temperature variations, from freezing cold to high heat. This makes them suitable for a wide range of operating conditions, contributing to their reliability in automotive applications.

3. Durability and Longevity The inherent strength and durability of EPDM contribute to the lifespan of fuel tank gaskets. Unlike traditional materials, EPDM does not degrade easily when exposed to ozone and UV light, allowing it to maintain its sealing capabilities over longer periods.

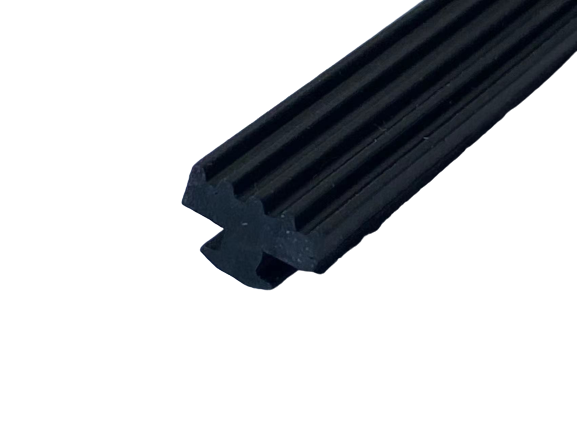

epdm automotive fuel tank gasket

4. Flexibility EPDM's flexibility enables it to conform to irregular surfaces and fit snugly within the fuel tank assembly. This adaptability is crucial for ensuring a proper seal, which is essential in preventing leaks.

Manufacturing Process

The manufacturing of EPDM automotive fuel tank gaskets typically involves a molding process. This process can include compression molding, injection molding, or extrusion methods.

1. Material Preparation The first step involves preparing the EPDM material, which is usually compounded with various additives, including accelerators, fillers, and plasticizers, to enhance its performance characteristics.

2. Molding Depending on the desired shape and application, the compounded EPDM is then formed using one of the molding techniques. The choice of method can impact the properties of the final gasket, including its elasticity and durability.

3. Curing After molding, the gaskets undergo a curing process, which involves applying heat or chemical agents. This step is critical, as it helps to cross-link the polymer chains, giving the gaskets their final strength and stability.

4. Quality Control Finally, the completed gaskets undergo rigorous testing to ensure they meet the required standards for performance and safety. This may include tests for chemical resistance, temperature tolerance, and sealing capability.

Conclusion

In summary, EPDM has emerged as a preferred material for automotive fuel tank gaskets due to its unique combination of properties. Its resistance to chemicals, durability, temperature tolerance, and flexibility make it ideal for ensuring a reliable seal in fuel systems. The significance of these gaskets cannot be overstated, as they play a pivotal role in vehicle safety and performance. As the automotive industry continues to evolve, the demand for high-quality, reliable components like EPDM gaskets will remain crucial for manufacturers seeking to deliver efficient and safe vehicles. By understanding the advantages of EPDM, automotive professionals can make informed decisions that enhance the overall quality and safety standards in the automotive sector.