Fev . 11, 2025 12:38 Back to list

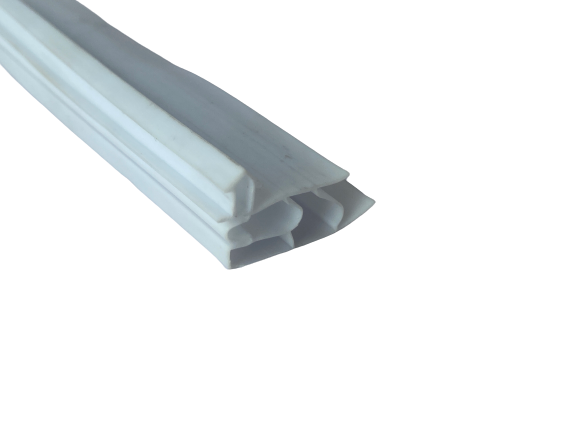

oem ship fender seal

Navigating the vast spectrum of maritime needs presents numerous challenges, one of which is selecting suitable OEM ship fender seals. These components are pivotal in safeguarding vessels against potential damage during mooring and docking processes. Understanding the nuances of these products can significantly impact the longevity of marine vessels and operational efficiency.

While technical excellence is imperative, authoritativeness in product selection also involves understanding certifications and compliance standards. Leading OEM suppliers pride themselves on adhering to stringent international maritime safety standards. Certifications such as ISO 9001 denote a supplier's commitment to quality management systems, ensuring that every product meets rigorous requirements for safety, reliability, and performance. For vessel operators and maritime corporations, selecting certified fender seals is not just a recommendation but a necessity in ensuring compliance and securing their investments. Trustworthiness in the OEM fender seal market is closely linked to reputation and customer reviews. A manufacturer renowned for delivering consistently high-quality products is invaluable. Recommendations from long-standing industry professionals and client testimonials should weigh heavily in the decision-making process. These endorsements reflect real-world performance and provide insights into the product's durability and reliability under duress. To make informed decisions, vessel operators should engage in active dialogues with OEM suppliers who can provide detailed insights into the product's performance records and testing results. Availability of aftersales support and warranties is also an indicator of a supplier's trustworthiness and dedication to customer satisfaction. In conclusion, selecting OEM ship fender seals involves a confluence of experience, expertise, authoritativeness, and trustworthiness. Emphasizing these fundamental components can lead to enhanced vessel safety, operational efficiency, and longevity. By recognizing the inherent value of expertly engineered fender seals, maritime stakeholders can safeguard their investments and ensure smoother sailing in literal and figurative terms. This approach guarantees a well-rounded and informed decision-making process, aligning with both financial prudence and safety priorities within the challenging and dynamic maritime domain.

While technical excellence is imperative, authoritativeness in product selection also involves understanding certifications and compliance standards. Leading OEM suppliers pride themselves on adhering to stringent international maritime safety standards. Certifications such as ISO 9001 denote a supplier's commitment to quality management systems, ensuring that every product meets rigorous requirements for safety, reliability, and performance. For vessel operators and maritime corporations, selecting certified fender seals is not just a recommendation but a necessity in ensuring compliance and securing their investments. Trustworthiness in the OEM fender seal market is closely linked to reputation and customer reviews. A manufacturer renowned for delivering consistently high-quality products is invaluable. Recommendations from long-standing industry professionals and client testimonials should weigh heavily in the decision-making process. These endorsements reflect real-world performance and provide insights into the product's durability and reliability under duress. To make informed decisions, vessel operators should engage in active dialogues with OEM suppliers who can provide detailed insights into the product's performance records and testing results. Availability of aftersales support and warranties is also an indicator of a supplier's trustworthiness and dedication to customer satisfaction. In conclusion, selecting OEM ship fender seals involves a confluence of experience, expertise, authoritativeness, and trustworthiness. Emphasizing these fundamental components can lead to enhanced vessel safety, operational efficiency, and longevity. By recognizing the inherent value of expertly engineered fender seals, maritime stakeholders can safeguard their investments and ensure smoother sailing in literal and figurative terms. This approach guarantees a well-rounded and informed decision-making process, aligning with both financial prudence and safety priorities within the challenging and dynamic maritime domain.