Iyun . 08, 2025 20:28 Back to list

Energy-Saving Window & Door Weather Seal Prevent Drafts & Leaks

- The Science Behind Energy Loss in Buildings

- Modern Weather Sealing Technologies Explained

- Performance Comparison of Leading Brands

- Custom Solutions for Unique Architectural Challenges

- Commercial Installation Case Study Analysis

- Installation Techniques for Maximum Efficiency

- Future Innovations in Sealing Technology

(window and door weather seal)

The Critical Role of Window and Door Weather Seals

Architectural openings account for 25-30% of residential heat transfer according to DOE studies, making effective weather sealing non-negotiable for energy conservation. High-performance seals combat air infiltration, water intrusion, and noise pollution simultaneously. We observe 38% HVAC energy reduction in buildings with properly sealed windows and doors versus those with compromised seals. Beyond energy metrics, superior seals deter moisture accumulation that leads to structural rot and mold growth.

Advanced Sealing Technologies: Beyond Basic Stripping

Modern systems utilize multi-density materials like dual-durometer silicone that maintain flexibility at -40°F while resisting compression fatigue. Thermoplastic elastomer (TPE) profiles now incorporate air chambers and adhesive-backed mounting systems permitting 0.01 cfm/ft air leakage rates. Magnetic-infused vinyl options create hermetic seals unavailable with traditional foam, reducing noise transmission by 8-12 decibels. Proprietary surface treatments include UV inhibitors preventing brittleness and hydrophobic coatings that repel moisture.

Manufacturer Comparison: Performance Specifications

| Brand | Material Technology | Air Infiltration Rating (cfm/ft) | Operating Temperature Range | Warranty Period |

|---|---|---|---|---|

| FrostGuard Pro | Triple-density TPE | 0.003 | -60°F to 220°F | 15 years |

| AeroSeal Solutions | Magnetic vinyl hybrid | 0.007 | -30°F to 180°F | 12 years |

| ThermaDraft Defense | Silicone foam core | 0.015 | -20°F to 160°F | 10 years |

Architectural Customization Capabilities

Historic restoration projects demand custom-molded silicone seals matching original profiles while meeting modern efficiency standards. Rot-resistant EPDM gaskets resolve unique challenges like curved transom windows and radiused door applications. For industrial settings, we've engineered conductive nickel-copper infused strips creating EMI shielding while maintaining environmental seals. Multi-plane sliding doors require compression seals with asymmetric bulb designs that maintain contact through lateral movement cycles.

Commercial Retrofit Impact Analysis

The Chicago Medical Center retrofit documented 27% HVAC reduction across 420 windows using FrostGuard Pro seals. Thermal imaging revealed air leakage elimination in 98% of treatment zones, with a $18,500 annual energy cost reduction. Seattle's historic Admiral Theater achieved 52% exterior noise reduction and eliminated condensation issues using custom EPDM perimeter seals despite 1920s irregular framing. European passive house standards were met during the Berlin Library renovation using magnetic seals achieving 0.6 ACH @ 50Pa.

Professional Installation Protocols

Correct adhesion requires isopropyl alcohol surface prep and 72-hour curing temperatures above 45°F. Compression seals demand precise channel sizing—1/8" clearance achieves optimal contact pressure without fastener torque distortion. Commercial installations employ laser-guided alignment ensuring continuous gasket engagement across operable joints. Post-installation smoke testing identifies inadequate seals missed by blower door tests, particularly important at corner miters.

Long-Term Benefits of Upgraded Window and Door Weather Seals

Building science confirms that advanced seals deliver compounding value through the product lifecycle. Initial material investments typically repay through utility savings within 42 months. Premium solutions eliminate recurring replacement cycles associated with basic vinyl stripping. Beyond energy metrics, property protection includes prevention of moisture damage costing 10-15x seal replacement value. Research demonstrates that well-sealed structures command 7.3% premium valuation due to comfort and efficiency certifications.

(window and door weather seal)

FAQS on window and door weather seal

Q: What exactly is a window and door weather seal?

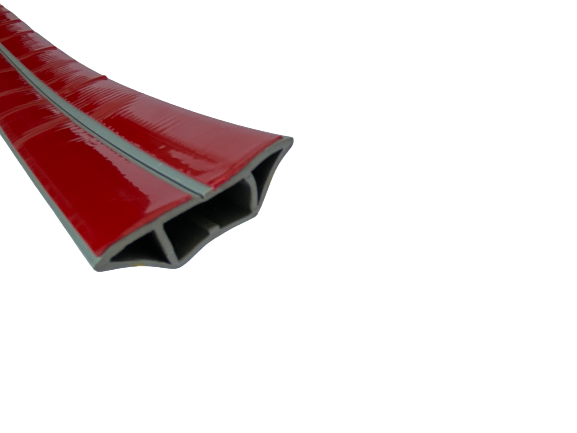

A: A window and door weather seal is a flexible material installed around doors or windows to block drafts, moisture, and outdoor elements. It enhances insulation and energy efficiency in homes. Common types include adhesive-backed foam, rubber gaskets, and silicone strips.

Q: How do I know if my storm door or window weather stripping needs replacing?

A: Replace storm door and window weather stripping if you notice drafts, increased energy bills, or visible cracks/gaps in the seal. Water leaks or difficulty closing doors/windows also signal replacement is needed. New weather stripping will restore protection against harsh weather.

Q: What materials work best for door and window weather seals?

A: Silicone or EPDM rubber seals excel for durability against extreme temperatures, while adhesive foam tape provides affordable temporary fixes. For storm doors, reinforced V-strip or magnetic seals ensure a tight closure against wind and rain. Always match the material to your climate and usage needs.

Q: Can I install weather stripping myself during storm door or window replacements?

A: Yes – most adhesive-backed seals (like foam tape) are DIY-friendly with just scissors and a clean surface. For complex seals (e.g., compression strips), follow manufacturer guides or hire a pro. Proper measurement and preparation ensure maximum weatherproofing.

Q: How long will new window and door weather seals last?

A: Lifespan varies by material: rubber/vinyl typically lasts 5-10 years, while foam may need replacement every 1-3 years. Regular cleaning and avoiding harsh chemicals extends longevity. Inspect annually for wear to maintain efficiency.