2 月 . 15, 2025 16:29 Back to list

L-shaped staircase anti-skid strip

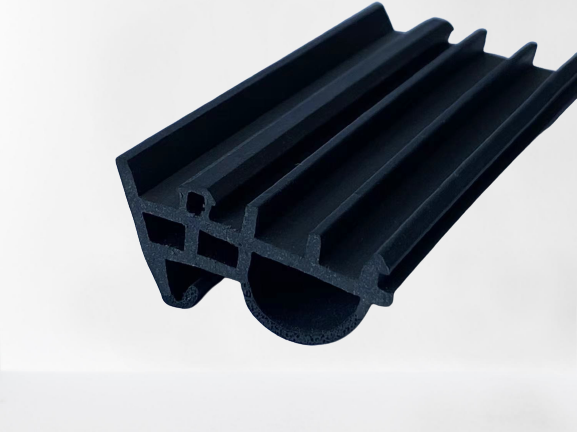

Navigating the realm of marine equipment requires both a keen eye and trusted expertise, especially when considering components like marine fender sealing strips. These underrated elements play a crucial role in safeguarding vessels against collision impacts, thus making their selection pivotal. Let's delve deep into the intricacies of choosing a cost-effective marine fender sealing strip without compromising on quality, offering insights driven by experience, expertise, authoritativeness, and trustworthiness.

In the implementation of cost-effective solutions, routine maintenance must not be overlooked. Regular inspections can preemptively identify signs of wear or damage, allowing for timely intervention. Cleaning the fender strips periodically with appropriate cleaning agents prescribed by the manufacturer prevents material degradation, ensuring continued performance and longevity. Engaging in a proactive maintenance routine fortifies the trustworthiness of your marine equipment over time. Economically savvy choices are further amplified by understanding the supplier landscape. The marine equipment market hosts a variety of suppliers, each promising unique offerings. A prudent approach entails evaluating suppliers based on reviews, their history in marine applications, and post-purchase support services. Suppliers who prioritize their customer’s long-term satisfaction by offering warranties and reliable support can become valuable partners. As environmental considerations increasingly impact purchasing decisions, exploring eco-friendly options in marine fender sealing strips can add to a vessel’s sustainability credentials. Some manufacturers are innovating with biodegradable materials or those with a lower carbon footprint, without sacrificing performance. Being at the forefront of such advancements not only enhances a brand’s authoritative stance but also contributes positively to the marine ecosystem. In conclusion, selecting the right marine fender sealing strip at an economical price involves a blend of material knowledge, trusted manufacturing practices, skilled installation, and routine maintenance. By focusing on these critical aspects, vessel owners can safeguard their investments without compromising on safety or performance. As the marine industry continues to evolve, staying informed about new technologies and materials ensures that your vessel remains both competitive and sustainable, reinforcing the cornerstones of expertise, authoritativeness, and trustworthiness in your marine endeavors.

In the implementation of cost-effective solutions, routine maintenance must not be overlooked. Regular inspections can preemptively identify signs of wear or damage, allowing for timely intervention. Cleaning the fender strips periodically with appropriate cleaning agents prescribed by the manufacturer prevents material degradation, ensuring continued performance and longevity. Engaging in a proactive maintenance routine fortifies the trustworthiness of your marine equipment over time. Economically savvy choices are further amplified by understanding the supplier landscape. The marine equipment market hosts a variety of suppliers, each promising unique offerings. A prudent approach entails evaluating suppliers based on reviews, their history in marine applications, and post-purchase support services. Suppliers who prioritize their customer’s long-term satisfaction by offering warranties and reliable support can become valuable partners. As environmental considerations increasingly impact purchasing decisions, exploring eco-friendly options in marine fender sealing strips can add to a vessel’s sustainability credentials. Some manufacturers are innovating with biodegradable materials or those with a lower carbon footprint, without sacrificing performance. Being at the forefront of such advancements not only enhances a brand’s authoritative stance but also contributes positively to the marine ecosystem. In conclusion, selecting the right marine fender sealing strip at an economical price involves a blend of material knowledge, trusted manufacturing practices, skilled installation, and routine maintenance. By focusing on these critical aspects, vessel owners can safeguard their investments without compromising on safety or performance. As the marine industry continues to evolve, staying informed about new technologies and materials ensures that your vessel remains both competitive and sustainable, reinforcing the cornerstones of expertise, authoritativeness, and trustworthiness in your marine endeavors.