12 月 . 03, 2024 23:58 Back to list

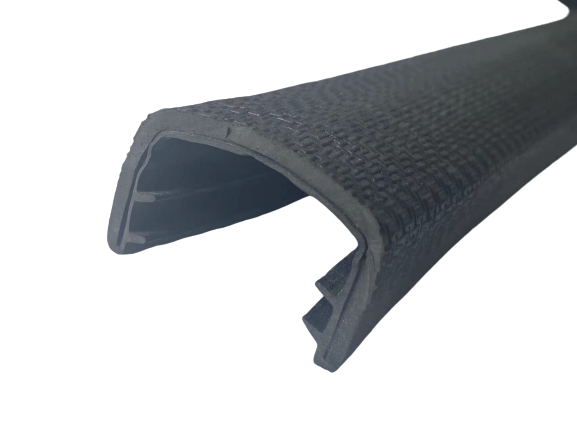

EPDM Rubber Seal Strips for Doors and Windows from Reliable Factories

EPDM Doors and Windows Rubber Seal Strip Factories A Gateway to Enhanced Insulation and Durability

In today's world, where energy efficiency and environmental sustainability are paramount, the significance of high-quality sealing solutions for doors and windows cannot be overstated. Among the various materials available, EPDM (Ethylene Propylene Diene Monomer) has emerged as a preferred choice in the construction and manufacturing industries. EPDM doors and windows rubber seal strips play a crucial role in ensuring effective insulation, preventing air and water leakage, and enhancing the overall durability of buildings. This article explores the importance of EPDM seal strips, their manufacturing process, and the role of factories producing these essential components.

The Importance of EPDM Seal Strips

EPDM is a synthetic rubber known for its excellent resistance to weathering, UV exposure, and ozone degradation. These properties make EPDM seal strips particularly suitable for use in doors and windows, where they are exposed to varying environmental conditions. One of the primary benefits of EPDM seal strips is their ability to create a tight seal, which significantly enhances energy efficiency by reducing the need for heating and cooling systems. This not only leads to lower energy bills for homeowners but also contributes to a smaller carbon footprint.

Furthermore, EPDM seals are versatile. They can be used in various applications, including residential, commercial, and industrial settings. Their flexibility and ability to conform to irregular shapes make them ideal for windows and doors of all sizes, ensuring that gaps are sealed effectively.

Manufacturing Process of EPDM Seal Strips

The production of EPDM doors and windows rubber seal strips involves several key steps to ensure quality and performance. Factories typically start with the formulation of raw materials, which includes mixing EPDM rubber with additives that enhance its properties. This mixture undergoes a process known as compounding, where it is blended to achieve the desired consistency and performance characteristics.

epdm doors and windows rubber seal strip factories

Once the rubber compound is ready, it is shaped into seal strips using various methods, including extrusion and molding. Extrusion involves pushing the rubber through a die to create continuous lengths of seal strips, while molding can be used to create specific profiles and shapes needed for particular applications. After shaping, the seal strips are cured in a process called vulcanization. This crucial step involves heating the rubber, causing it to chemically bond and transform into a durable material capable of withstanding the rigors of everyday use.

Quality Control in EPDM Seal Strip Factories

Quality control is a critical aspect of EPDM seal strip manufacturing. Reputable factories implement stringent quality checks at every stage of production. This includes testing for physical properties such as tensile strength, elongation, and hardness, as well as resilience to environmental factors like temperature and humidity. By adhering to industry standards and certifications, these factories ensure that their products are reliable and long-lasting.

Moreover, customer feedback plays an essential role in the continuous improvement of products. Factories often collaborate with architects, builders, and end-users to gain insights into the performance of their seal strips in real-world applications. This collaboration fosters innovation and the development of new products that meet changing market demands.

Conclusion

In conclusion, EPDM doors and windows rubber seal strip factories are instrumental in providing high-quality sealing solutions that enhance energy efficiency, durability, and comfort in buildings. The unique properties of EPDM material combined with a meticulous manufacturing process ensure that these seal strips meet the demands of modern construction. As the focus on sustainability and energy conservation continues to grow, the importance of EPDM seal strips in the building industry will remain pivotal, making them an indispensable component for any construction project. Ultimately, investing in quality EPDM seals is not just a choice for today but a commitment to a more sustainable and efficient future.