11 月 . 11, 2024 12:17 Back to list

epdm rubber sheet density

Understanding EPDM Rubber Sheet Density

EPDM (Ethylene Propylene Diene Monomer) rubber is a versatile and widely used synthetic rubber that exhibits excellent properties suitable for various applications, particularly in roofing, automotive, and industrial sectors. One significant aspect that often comes into consideration when using EPDM rubber sheets is their density. Understanding the density of EPDM rubber sheets is crucial for engineers, designers, and end-users, as it influences the material's performance, durability, and overall application.

What is Density?

Density is a measure of how much mass is contained in a given volume, usually expressed in grams per cubic centimeter (g/cm³) or pounds per cubic foot (lb/ft³). In the case of EPDM rubber sheets, the density can indicate the material's composition and affect its mechanical properties, including tensile strength, compressibility, and thermal stability. Generally, the density of EPDM rubber ranges from 0.86 to 1.65 g/cm³, with variations based on the formulation and manufacturing process.

Factors Influencing EPDM Rubber Sheet Density

1. Composition The density of EPDM rubber is influenced by its chemical composition. The ratio of ethylene to propylene in the polymer chains, as well as the presence of various fillers and additives, can significantly affect its density. Higher amounts of fillers, like carbon black, will generally increase the density of the rubber sheet.

2. Curing Process The curing or vulcanization process used in manufacturing EPDM can also impact the final density. Depending on the type and amount of curative agents used, the molecular structure can change, subsequently altering the rubber's density.

3. Thickness and Formulation The thickness of the rubber sheet itself can affect its overall weight and density. While a thicker sheet might retain the same density, it will inherently weigh more than a thinner one. Additionally, specialized formulations for specific applications can yield varying densities.

4. Temperature and Environmental Factors The density of rubber can change with temperature. EPDM rubber has a relatively stable density over a wide temperature range, but extreme heat or cold can lead to minor fluctuations.

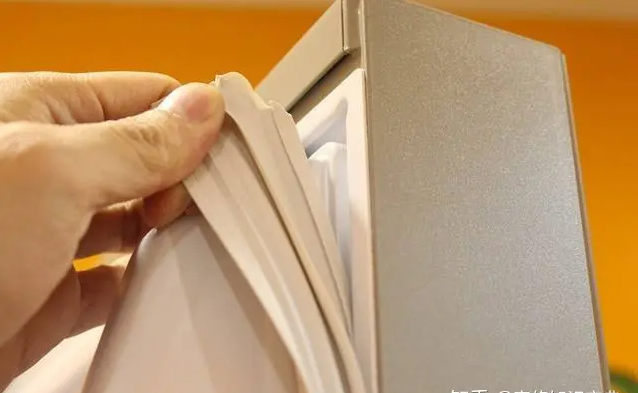

epdm rubber sheet density

Importance of Knowing Density

Understanding the density of EPDM rubber sheets is essential for several reasons

- Performance Evaluation The density can directly influence the performance characteristics of the rubber, such as how well it resists compression, fatigue, and environmental exposure. A higher density often correlates with improved durability and resistance to wear.

- Weight Calculations For applications where weight is a critical factor (such as in automotive parts or aerospace components), knowing the density allows for accurate weight calculations, which are crucial for efficiency and safety.

- Material Selection Engineers and designers need to account for density when selecting materials for specific applications. A material that is too dense may not be suitable for lightweight applications, while a material that is too lightweight may lack the necessary durability.

- Cost Considerations The density can also impact the cost of EPDM rubber sheets. Higher density materials may be more expensive due to the additional fillers and processing steps involved, so budget considerations often necessitate a balance between density, performance, and cost.

Conclusion

In summary, the density of EPDM rubber sheets is a vital characteristic that affects their usage across various industries. By understanding the factors that influence density and recognizing its importance in application performance, designers and engineers can make informed choices about the materials they use. Whether for waterproofing systems, automotive components, or industrial seals, EPDM rubber offers an array of benefits, and its density is a key component in harnessing those advantages effectively. As industries continue to evolve, the innovative use of EPDM rubber and its properties, including density, will play a crucial role in advancing technology and materials science.