11 月 . 25, 2024 19:49 Back to list

ODN NBR Rubber Sheets 1-20mm Thickness for Versatile Industrial Applications

The Versatility of ODM NBR Rubber Plates A Comprehensive Overview

Nitrile Butadiene Rubber (NBR), commonly known as nitrile rubber, is renowned for its excellent oil and petroleum resistance, making it a popular choice in various industrial applications. Among its numerous forms, the ODM NBR rubber plate measuring 1-20mm has gained significant attention due to its versatility, durability, and effectiveness in diverse environments. This article delves into the characteristics, benefits, and applications of ODM NBR rubber plates.

Characteristics of ODM NBR Rubber Plates

ODM NBR rubber plates are manufactured to provide superior performance in challenging conditions. The thickness of 1-20mm offers flexibility in application, allowing users to select the appropriate thickness based on their specific needs. With its robust structure, NBR rubber can withstand high temperatures and resist degradation brought about by exposure to oils, fuels, and chemicals. Additionally, its excellent tear and abrasion resistance enhances its longevity, making it an economical choice for various applications.

Benefits of using ODM NBR Rubber Plates

1. Chemical Resistance One of the standout features of NBR rubber is its remarkable resistance to oil, greases, and various chemicals. This property makes ODM NBR rubber plates suitable for applications in the automotive, aerospace, and machinery industries, where exposure to such substances is commonplace.

2. Durability The resilience of NBR rubber against wear, tear, and environmental factors ensures a long service life. When used in demanding settings, these rubber plates maintain their integrity, reducing the need for frequent replacements.

3. Versatility ODM NBR rubber plates are available in various thicknesses ranging from 1mm to 20mm, making them adaptable to a wide range of applications. Whether in sealing applications, vibration dampening, or as spacers, their versatility is unmatched.

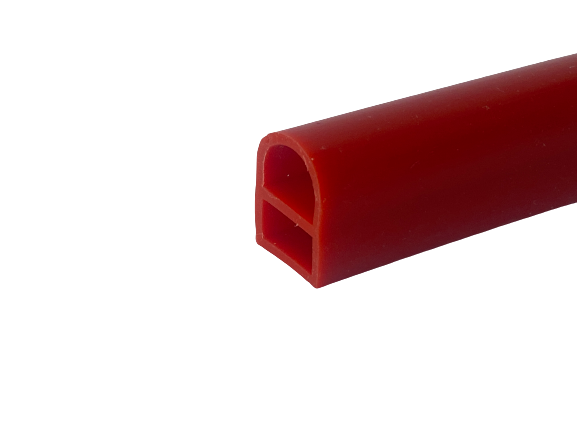

odm nbr rubber 1-20mm rubber plate

4. Cost-Effective Given their durability and low maintenance requirements, ODM NBR rubber plates represent an economical investment. Reduced downtime and fewer replacements contribute to overall cost savings for businesses.

5. Customization Manufacturers often offer customization options for NBR rubber plates to meet specific requirements. Custom sizes, shapes, and hardness levels can be tailored to suit unique industrial needs, providing an added layer of functionality.

Applications of ODM NBR Rubber Plates

The applications of ODM NBR rubber plates are extensive and diverse. In the automotive industry, they are frequently used in fuel systems, gaskets, and seals, where resistance to petroleum-based products is crucial. Additionally, in the industrial sector, these plates serve as protective barriers and linings in machinery and equipment to minimize wear and prevent contaminants from entering sensitive areas.

In the construction industry, ODM NBR rubber plates are utilized for sound insulation and vibration dampening, contributing to healthier and quieter working environments. Furthermore, in the food and pharmaceutical industries, NBR rubber is used in equipment that requires compliance with strict hygiene standards due to its non-toxic properties.

Conclusion

ODM NBR rubber plates, with their unique characteristics and plethora of benefits, have become indispensable in various industries. The combination of durability, chemical resistance, and versatility ensures that they meet the demands of modern industrial applications, making them a smart choice for businesses looking to enhance their operations. As industries continue to evolve, the role of NBR rubber plates is poised to expand, solidifying their position as key components in achieving efficiency and reliability across multiple sectors.