1 月 . 01, 2025 09:29 Back to list

Creating Effective Sealing Solutions with Panel Sealing Strips for Optimal Performance

The Importance and Benefits of Panel Sealing Strips

In the world of construction and manufacturing, the significance of panel sealing strips cannot be overstated. These seemingly simple components play a crucial role in ensuring the durability, efficiency, and functionality of various assemblies. From residential buildings to industrial machinery, panel sealing strips serve to provide crucial protection and insulation.

What Are Panel Sealing Strips?

Panel sealing strips are flexible materials, often made from rubber, foam, or silicone, designed to fill gaps between panels, doors, or windows. Their primary purpose is to prevent air and water infiltration, thereby enhancing insulation and energy efficiency. By creating a tight seal, these strips help maintain a stable indoor temperature and minimize energy consumption, leading to both environmental and financial benefits.

Applications in Various Industries

Panel sealing strips find applications in numerous industries. In the construction sector, they are commonly used in doors and windows to reduce drafts and improve energy efficiency. In manufacturing, these strips are essential in machinery assembly to prevent leakage of fluids and protect sensitive components from dust and debris. In automotive industries, they help in noise reduction and water protection, ensuring a quiet and comfortable ride for passengers.

Benefits of Using Panel Sealing Strips

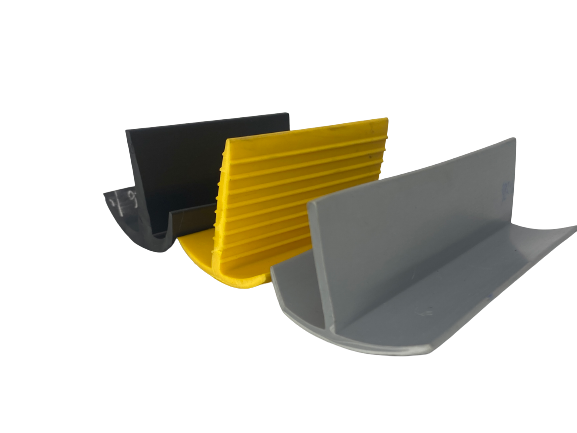

panel sealing strip

1. Energy Efficiency One of the most significant benefits of panel sealing strips is their ability to enhance energy efficiency. By sealing gaps, they reduce the amount of heated or cooled air that escapes a building. This not only leads to a more comfortable indoor environment but also reduces energy costs, allowing homeowners and businesses alike to save money on heating and cooling.

2. Protection Against Environmental Elements Panel sealing strips provide a barrier against water, dust, and noise. Buildings equipped with high-quality sealing strips are less likely to suffer from water damage, mold growth, or pest invasion. This protection ultimately leads to lower maintenance costs and prolonged lifespan for buildings and equipment.

3. Improved Comfort In spaces where temperature and noise control are paramount, panel sealing strips significantly enhance the overall comfort. They not only help in keeping spaces warmer during winters and cooler during summers but also reduce external noise, creating a more peaceful environment.

4. Versatility Available in various shapes, sizes, and materials, panel sealing strips can be tailored to fit specific needs. Whether for home use, industrial applications, or automotive manufacturing, there’s a sealing strip designed for every purpose.

5. Ease of Installation Many panel sealing strips are designed for easy installation, requiring minimal tools and expertise. This user-friendly attribute allows both manufacturers and DIY enthusiasts to incorporate them into their projects without extensive training.

Conclusion

In conclusion, panel sealing strips are an integral component in ensuring the efficiency and durability of various structures and machines. Their applications span multiple industries, including construction, manufacturing, and automotive, highlighting their versatility and importance. With benefits ranging from energy savings to enhanced protection against environmental elements, these strips are a smart investment for anyone looking to improve the functionality and longevity of their assets. As awareness of energy efficiency and environmental impact grows, the demand for effective solutions like panel sealing strips will undoubtedly continue to rise, making them a timeless necessity in modern construction and manufacturing practices.