11 月 . 17, 2024 16:43 Back to list

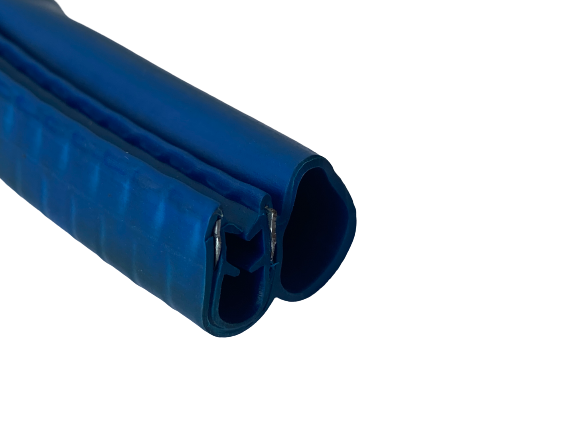

ship fender seal product

Understanding Ship Fender Seal Products Essential for Marine Safety

In the marine industry, ensuring the safety of vessels during docking and mooring operations is paramount. One of the key components that play a critical role in this aspect is the ship fender seal product. These specialized devices not only protect ships from accidental collisions but also safeguard docking facilities and enhance overall operational efficiency. This article explores the importance of ship fender seals, their types, materials, and maintenance practices.

What is a Ship Fender Seal?

A ship fender seal is a form of protective cushioning installed on docks, piers, or ships to absorb the kinetic energy resulting from a vessel’s impact. These seals are designed to minimize damage to both the ship and the docking structure during berthing. They serve as a barrier, providing a safe buffer that can withstand the harsh marine environment while ensuring smooth transfer during loading and unloading processes.

Types of Ship Fenders

There are various types of ship fenders available, each designed to fulfill specific operational needs

1. Inflatable Fenders These are made from durable rubber and are filled with air, allowing them to absorb impact effectively. Inflatable fenders are versatile and can be used in various applications, including ship-to-ship transfers.

2. Foam Fenders Constructed from closed-cell foam and covered with a tough outer layer, foam fenders are known for their lightweight and resilience. They maintain their shape and damage resistance even after numerous impacts.

3. Solid Rubber Fenders These fenders are robust and durable, ideal for areas with high traffic where heavy-duty protection is essential. They provide a long service life with minimal maintenance.

4. Polyurethane Fenders Known for their excellent abrasion and weather resistance, polyurethane fenders have a long lifespan, making them suitable for harsh marine environments.

ship fender seal product

5. Arch Fenders These are semi-cylindrical fenders installed horizontally and provide good energy absorption. They are often used in large berths.

Materials Used in Ship Fender Seals

The materials used to manufacture ship fender seals are critical in determining their durability and effectiveness. Common materials include

- Natural Rubber Offers excellent elasticity and resilience, making it ideal for fender production. - Synthetic Rubber Increases the fender’s resistance to oil, ozone, and UV rays, providing longevity in varying environmental conditions.

- Polyethylene and Polyurethane These materials enhance the fender's impact resistance and protection against abrasion.

Importance of Regular Maintenance

To ensure the longevity and effectiveness of ship fender seals, regular maintenance is vital. Inspecting fenders for wear and tear should be routine practice. Signs of damage include cracks, deformation, or loss of buoyancy. Proper cleaning and maintenance help to remove debris and prevent deterioration, extending the lifespan of the fenders and ensuring maximum safety during operations.

Conclusion

Ship fender seal products are indispensable in the marine industry, serving as a primary line of defense against potential collisions and damage during berthing. With various types and materials available, selecting the right fender seal is crucial for ensuring the safety and efficiency of docking operations. Regular maintenance and inspections further enhance the effectiveness and lifespan of these essential marine components, underscoring their vital role in promoting safe and efficient maritime operations. As the marine industry continues to grow, investing in quality ship fender seals remains a priority for ship operators and port authorities alike.