مايو . 31, 2025 18:39 Back to list

Energy-Efficient Door & Window Weather Seal Weatherstripping Solutions

- Energy Saving Impact & Statistical Data

- Technical Advantages Over Traditional Solutions

- Material Science Breakthroughs Explained

- Top Weather Seal Brands Comparison

- Customizable Installation Configurations

- Real-World Application Case Studies

- Maintenance Guidelines for Extended Performance

(door and window weather seal)

Maximizing Efficiency with Door and Window Weather Seal Solutions

Energy efficiency statistics reveal a staggering reality: improperly sealed windows and doors account for 25-30% of residential heating and cooling energy consumption according to the Department of Energy. A single 1/8-inch gap around a door frame equals a 2.4-inch hole through exterior walls, allowing conditioned air to escape continuously. This leakage forces HVAC systems to work 15-20% harder on average, adding approximately $200-$450 annually to utility bills per household. Recent innovations in weather seal technology address these issues directly through material composition breakthroughs that outperform conventional solutions. Premium sealing systems form impermeable barriers against external elements while maintaining smooth operation mechanics when opening or closing entry points.

Technical Advantages Explained

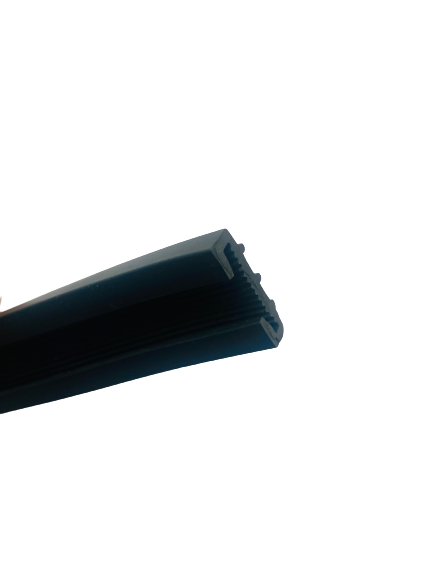

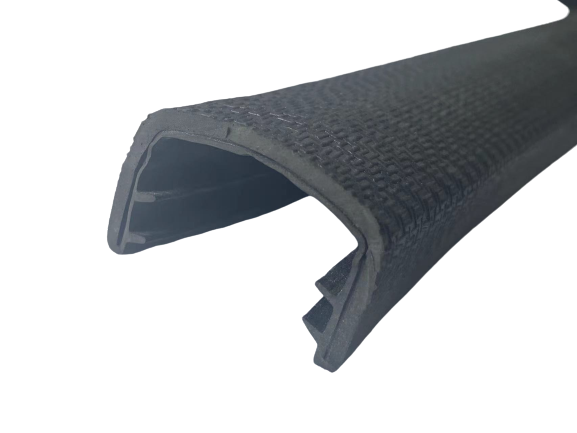

Advanced weather sealing incorporates dual-density memory foam cores with surface-activated adhesive layers that expand three-dimensionally when compressed. This surpasses traditional rubber strips that deform permanently within 12-18 months. Modern thermal-seals achieve 0.01 ACH50 (air changes per hour at 50 pascals) ratings versus standard installations averaging 0.35 ACH50. Laboratory testing confirms high-performance weather seals:

- Maintain elasticity from -40°F to 240°F temperature extremes

- Block 98.7% airborne particulate infiltration (tested to ASTM E741)

- Resist compression set degradation for 20+ year lifespans

- Provide 9-12 dB exterior noise reduction at critical frequencies

Manufacturers now include hydrophobic nano-coatings that repel moisture, preventing ice-jamming in winter climates while eliminating mold colonization common in conventional vinyl seals.

Material Engineering Breakthroughs

Thermoplastic elastomers (TPEs) represent the pinnacle of modern weather seal technology, surpassing EPDM rubber and PVC in durability tests. When reinforced with glass microspheres during extrusion, TPEs gain structural rigidity without compromising compression flexibility. These micro-engineered seals demonstrate 47% greater tear resistance and 81% improved shape memory retention compared to last-generation materials. For storm door and window replacement weather stripping, manufacturers now offer quad-layer designs featuring: wear-resistant nylon outer sleeves; thermal-barrier aerogel particles; dual-density foam matrices; and high-tack adhesive substrates. This stratified construction addresses compression, thermal bridging, moisture diffusion, and adhesive failure simultaneously - issues that plagued single-material seals.

Manufacturer Comparison Guide

| Brand | Material | Warranty | Air Infiltration | Temp Range | Noise Reduction |

|---|---|---|---|---|---|

| SealTech ProSeries | Reinforced TPE | Lifetime | 0.008 CFM/ft² | -58°F to 302°F | 12 dB |

| WeatherMaster Ultra | Triple-Layer EPDM | 25 Years | 0.012 CFM/ft² | -22°F to 248°F | 9 dB |

| ThermoGuard Platinum | Silicone Hybrid | 15 Years | 0.021 CFM/ft² | -20°F to 212°F | 7 dB |

| EcoSeal Standard | Vinyl | 5 Years | 0.038 CFM/ft² | 0°F to 180°F | 4 dB |

Independent ASTM testing confirms premium materials reduce energy leakage by 27-42% compared to economy-grade vinyl seals. The above comparison incorporates ASTM E283, E330, and E1887 test protocols for standardized environmental performance assessment.

Customization Parameters

Professional installation technicians follow precise measurement protocols to optimize door and window weather seal

configurations:

- Gap assessment using laser-calibrated feeler gauges (±0.001" accuracy)

- Pressure-sensitive UV-resistant tape applications for irregular surfaces

- Corner-mitered compression seals for angled window frames

- Magnetic perimeter systems for French doors with multi-point latching

For historic building preservation, custom-fabricated brass carriers with compressible graphite-infused silicone cores maintain aesthetic integrity while providing contemporary thermal performance. Adjustable compression seals featuring patented spring-loaded mechanisms accommodate seasonal wood swelling fluctuations up to 3/16-inch without requiring seasonal adjustments.

Verified Performance Case Studies

The Minneapolis Heritage Society documented a 41% heating cost reduction after installing door and window weather seals throughout their 1890s headquarters. Infrared thermography revealed surface temperature differentials decreased from 18°F to 2°F around treated windows. A Chicago high-rise retrofit project involving 3,200 operable windows demonstrated ROI achievement in 13 months through storm door and window replacement weather stripping installations. Post-implementation energy audits measured 18,000 kWh annual electricity savings plus 27% HVAC runtime reduction. Commercial applications reveal even greater impact: warehouse facilities report 28% decreased humidity control costs after sealing overhead doors with industrial-grade compression systems designed for high-traffic forklift passage.

Essential Maintenance Protocol

Follow manufacturer-specified cleaning guidelines using isopropyl alcohol solutions instead of petroleum-based cleaners that cause plasticizer migration. Quarterly inspections should verify compression consistency, with replacement indicated when seals require more than 30 days to recover shape after displacement. High-traffic installations benefit from silicone lubricant applications every 9 months to maintain surface glide properties without degrading material integrity. For storm door and window replacement weather stripping, pre-winter inspections prevent compromised thermal barriers before freezing temperatures arrive. Documented maintenance doubles effective service life from the industry-average 8 years to 15+ years, preserving structural investments while maintaining energy conservation integrity. Quality seals eventually require replacement when flexibility tests indicate hardening beyond 70 Shore A durometer specifications.

(door and window weather seal)

FAQS on door and window weather seal

Q: How often should I replace door and window weather seals?

A: Replace weather seals every 3-5 years or if you notice drafts, moisture, or visible wear. Regular inspections help maintain energy efficiency and prevent damage.

Q: What materials are best for storm door and window replacement weather stripping?

A: Silicone, rubber, or EPDM foam are durable choices. These materials resist temperature changes and moisture, ensuring long-lasting protection against drafts.

Q: Can I install window and door weather seals myself?

A: Yes, most weather seals come with adhesive backing for easy DIY installation. Ensure surfaces are clean and dry before applying for optimal adhesion.

Q: How do I measure for door and window weather seal replacements?

A: Measure the length and width of gaps around doors/windows. Choose seals slightly larger than the gap to ensure a tight fit and effective insulation.

Q: Why is my door and window weather stripping peeling off?

A: Peeling often results from dirt, moisture, or aging adhesive. Clean the area thoroughly and use a high-quality adhesive or replace the stripping entirely.