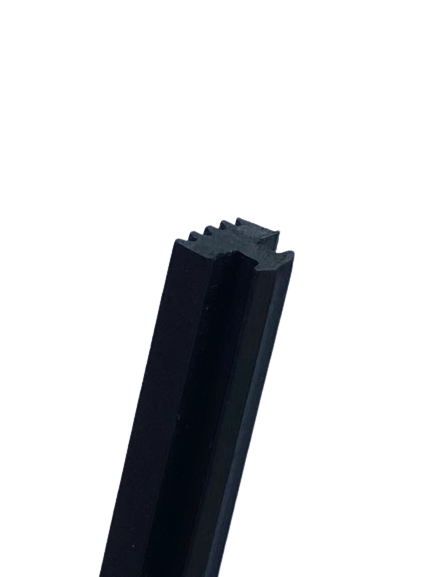

What is rubber strip?

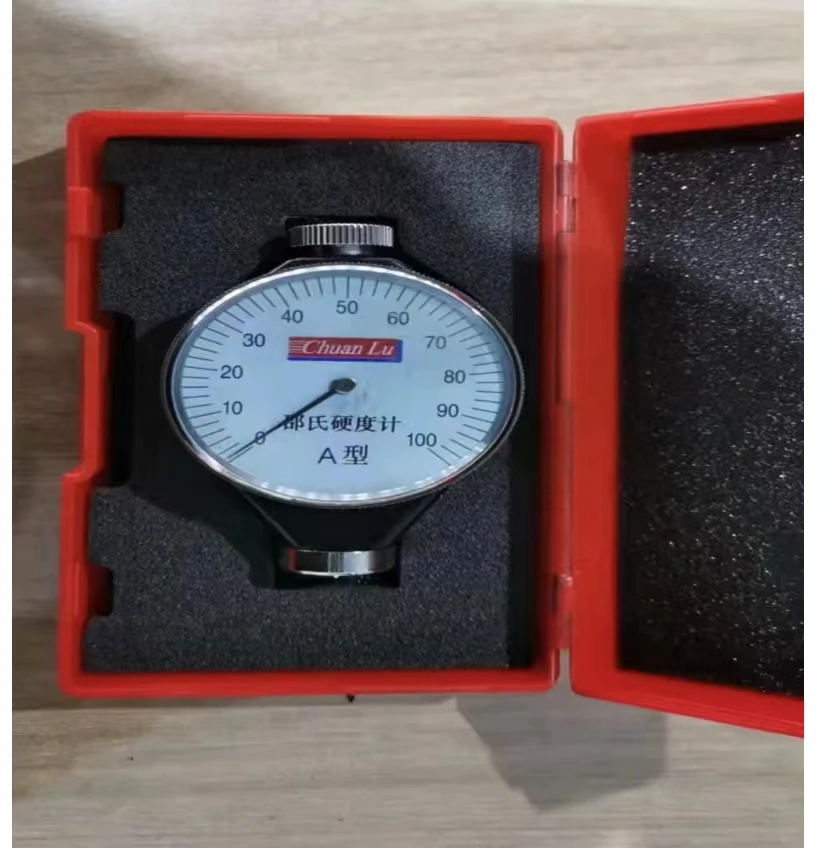

The rubber strip is an elastic strip or rod material installed at the joint of glass and bead, glass and frame fan, frame and fan, and between fan and fan to prevent water, dust and air leakage, reduce the damage to doors and windows caused by vibration and impact, and thus seal, sound insulation, heat insulation and shock absorption. The rubber strip is a very important part in the door and window curtain wall. The above function determines that a good rubber strip must have excellent resistance to the deterioration of ultraviolet aging, ozone aging, heat and oxygen aging, as well as low compression permanent deformation and creep, high and low temperature resistance and rain water resistance. In terms of processing technology, the rubber compound should also have the characteristics of easy extrusion, small shrinkage deformation and good flexibility. It can be said that it is a small adhesive strip. Its function is not small. The greater the use, the higher the requirements.

Generally speaking, at present, there are several materials commonly used for sealant strips for building doors and windows and curtain walls: EPDM, MVQ, CR, TPV, TPU, TPE, PPVC, etc.Among the materials listed above, EPDM rubber with high filling reinforcement and multiple physical and chemical aging prevention systems has become the preferred sealant strip material. Because TPE has both the physical and mechanical properties of rubber and the processing characteristics of plastics, it has gradually become an ideal material to replace rubber and plastics in recent years. Because TPE also has some difficulties in manufacturing sponge in the process and needs special technology, its use is limited to a certain extent. At present, TPE is mainly used for frame fans and the outside of glass. Although TPV is closer to rubber, its high price has also become another factor affecting the promotion. Today, the materials used for sealant strips have begun to show a trend of diversified development. Different materials are often selected according to the use position, purpose and required characteristics, and according to the service life and cost price. In the long run, the application range of environmental protection and energy saving TPV on sealant strips will also continue to expand.

Company name: Hebei Zhouge Plastic Technology Co., Ltd

Tel:+86 13833943677

WhatsAPP:+86 13833943677

E-mail: hebeizhouge@163.com

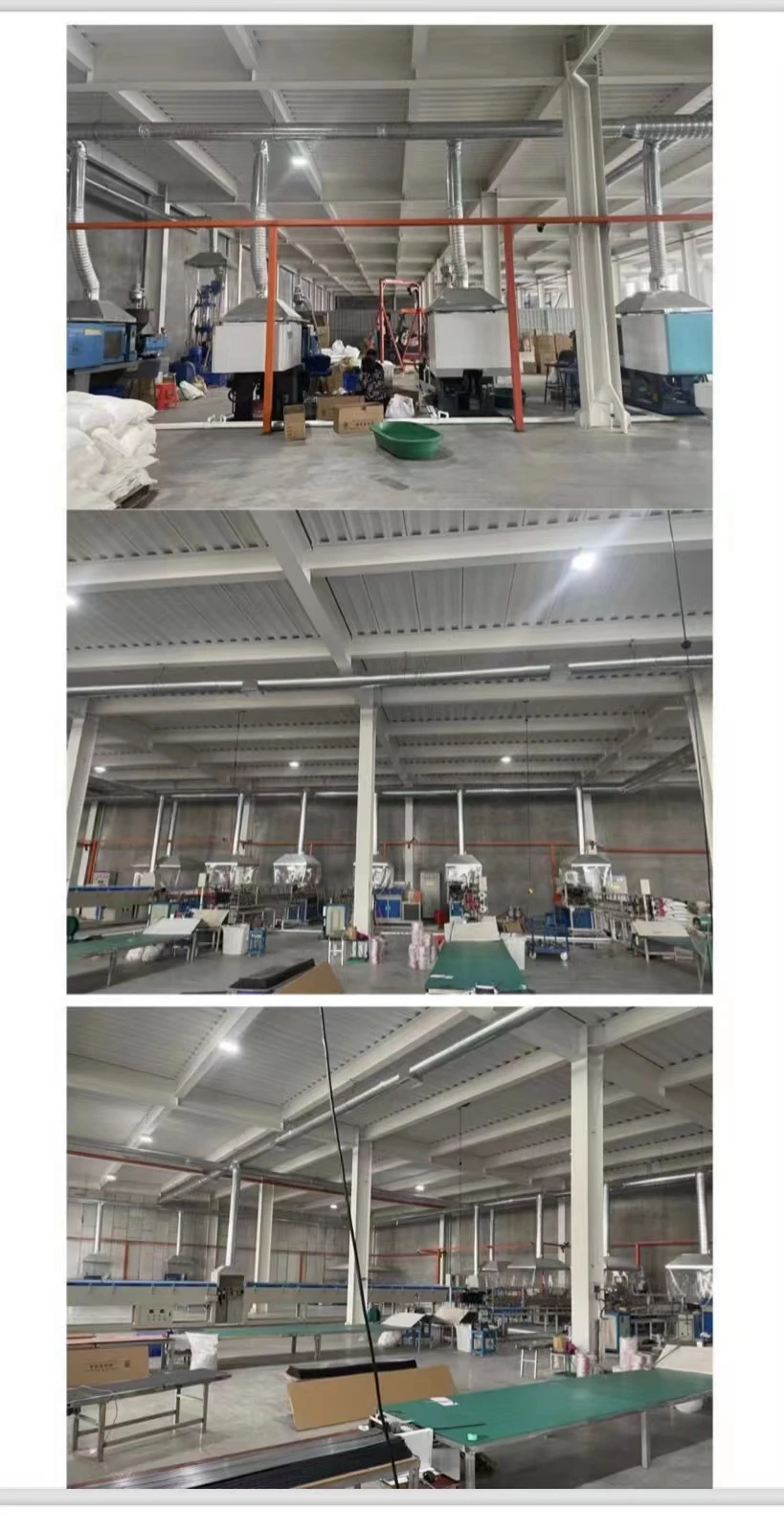

Hebei Zhouge Plastic Technology Co., Ltd. was established in 2014 and is committed to providing one-stop protection for fire prevention, smoke prevention, sound insulation, ventilation and sealing. By implementing this strategy, we have achieved a leading advantage. Firstly, provide cost-effective and reliable products for customers; Secondly, by integrating different product solutions to meet customer needs; Third, provide customers with one-stop, differentiated quality services, including detailed design, material solution consulting, supply chain management, quality control and financial support; Finally, always maintain innovation in technology and management.