Dic . 13, 2024 20:50 Back to list

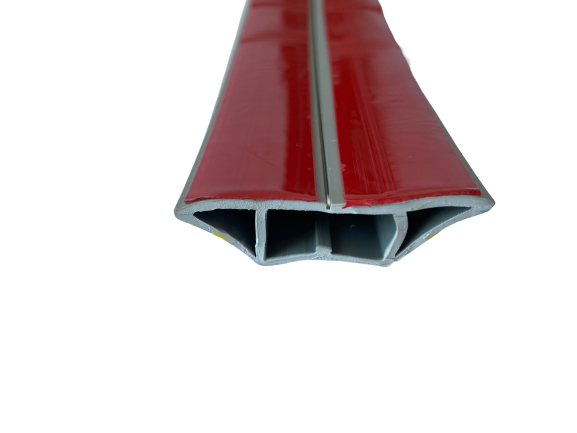

anti-collision rubber seal for ship type d factory

Anti-Collision Rubber Seal for Ships Type D Solutions from Factories

In the maritime industry, safety and efficiency are paramount. As vessels navigate the vast oceans, they face various challenges, including potential collisions with other ships or marine structures. One crucial component in enhancing ship safety is the anti-collision rubber seal, particularly those classified under Type D. This article explores the significance, functionality, and advancements of Type D anti-collision rubber seals produced by modern factories.

Understanding Anti-Collision Rubber Seals

Anti-collision rubber seals are designed to provide an effective barrier that minimizes impact during collisions. They are typically installed along the hull of ships, serving as protective buffers against external shocks. The primary purpose of these seals is to absorb kinetic energy during an impact, thus preventing damage to both the vessel and other structures in case of unintended contact.

The Importance of Type D Seals

Type D rubber seals are specifically engineered to meet rigorous maritime standards. These seals are characterized by their robust design and excellent cushioning properties, making them suitable for a wide range of vessels, from cargo ships to passenger ferries. The unique shape and material composition of Type D seals enhance their performance, ensuring maximum safety and resilience against harsh marine environments.

The adoption of Type D seals is particularly important in areas where heavy traffic is expected, such as harbors and docking facilities. In these zones, the risk of collision is significantly higher, and having an effective anti-collision system is crucial. Type D seals not only protect the ship itself but also safeguard port infrastructure, reducing repair costs and downtime.

Manufacturing Process and Quality Assurance

The production of Type D anti-collision rubber seals involves sophisticated manufacturing processes that adhere to strict quality standards. Factories utilize advanced machinery and high-grade materials, ensuring that each seal is durable and long-lasting. The rubber compounds used in Type D seals are designed to withstand extreme weather conditions, UV exposure, and corrosive marine elements.

anti-collision rubber seal for ship type d factory

Quality assurance is also a critical aspect of the manufacturing process. Each batch of seals undergoes rigorous testing to evaluate its performance under various conditions. This includes assessments of elasticity, tensile strength, and impact resistance. By prioritizing quality, manufacturers ensure that Type D anti-collision rubber seals consistently meet the safety and durability expectations of ship operators.

Innovations in Design and Materials

The maritime sector is continually evolving, driven by advancements in technology and materials science. Recent innovations in the design of Type D anti-collision seals have led to the incorporation of smart materials that offer enhanced functionality. For instance, some modern seals are designed with energy-absorbing properties that increase their efficiency during a collision.

Moreover, the use of environmentally friendly materials has become increasingly popular in seal production. These sustainable materials do not compromise on performance while reducing the environmental impact of production processes. Ship operators are increasingly seeking products that align with global sustainability goals, and Type D seals made from eco-friendly materials cater to this demand.

Conclusion

The importance of anti-collision rubber seals, particularly Type D, cannot be overstated in ensuring the safety and longevity of maritime vessels. As ships continue to navigate crowded waters, the risks of accidents remain significant. Investing in high-quality Type D anti-collision rubber seals produced by reputable factories is essential for maritime operators aiming to enhance safety and reduce repair costs.

With ongoing innovations in design and materials, the future of anti-collision seals looks promising. As the industry embraces new technologies and sustainable practices, Type D seals are poised to become even more effective and reliable. Ultimately, prioritizing safety through the deployment of advanced anti-collision systems will lead to safer seas and a more resilient maritime industry.

In summary, as shipbuilders and operators recognize the critical role of Type D anti-collision rubber seals, the focus will remain on quality manufacturing and innovative technologies to meet the evolving demands of the maritime landscape. The journey towards safer seas is ongoing, and Type D seals will undoubtedly play a pivotal role in shaping that future.