Nov . 05, 2024 15:16 Back to list

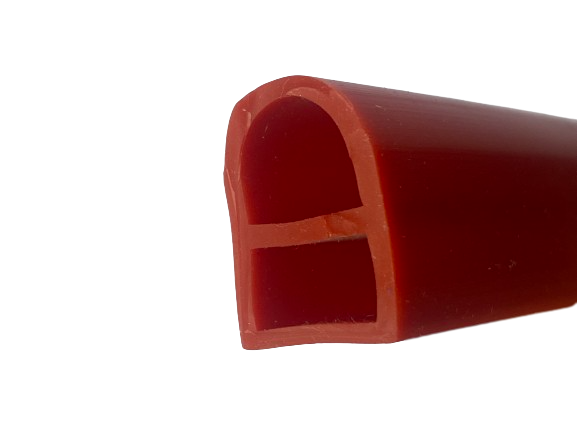

1 8 neoprene rubber sheet

Understanding 1% 208% Neoprene Rubber Sheets Characteristics and Applications

Neoprene rubber, a synthetic elastomer developed by DuPont in the 1930s, is known for its excellent chemical stability, flexibility, and resilience. Among the various formulations of neoprene rubber, the 1% 208% neoprene rubber sheet has gained significance in multiple industries due to its unique properties and versatility. This article delves into the characteristics, advantages, and applications of 1% 208% neoprene rubber sheets.

Characteristics of 1% 208% Neoprene Rubber Sheets

The notation 1% 208% typically refers to the composition and performance metrics of the neoprene rubber. The 1% indicates the percentage content of specialty additives or fillers that enhance certain properties, while 208% signifies the material's elongation at break, denoting how much it can stretch before failing. This high elongation rate makes 1% 208% neoprene sheets inherently flexible and resilient, crucial for numerous applications.

One of the key features of neoprene rubber is its excellent resistance to various environmental factors, including water, oils, and ozone. It can withstand extreme temperatures ranging from -40°F to 200°F (-40°C to 93°C), allowing it to maintain its integrity and functionality across diverse conditions. This heat and cold resistance, combined with good tensile strength and elasticity, makes neoprene a preferred material in many applications.

Advantages of 1% 208% Neoprene Rubber Sheets

1. Chemical Resistance Neoprene's resistance to oils, solvents, and other chemicals ensures prolonged product life, making it suitable for industries dealing with various corrosive materials.

2. Waterproof and Weatherproof This rubber sheet provides excellent waterproofing capabilities, making it ideal for applications requiring moisture resistance.

3. Durability High tensile strength and resistance to wear and tear extend the lifespan of products made from 1% 208% neoprene.

4. Flexibility and Comfort With a high elongation percentage, neoprene sheets can easily conform to various shapes and surfaces, offering comfort in wearables and protective gear.

1 8 neoprene rubber sheet

Applications of 1% 208% Neoprene Rubber Sheets

The versatile properties of 1% 208% neoprene rubber sheets lead to a wide array of applications across different sectors

1. Automotive Industry Used to produce gaskets, seals, and hoses, neoprene enhances the durability and performance of automotive components by providing resistance to oil and wear.

2. Construction and Insulation Its waterproof and weatherproof properties make it an excellent choice for insulation materials in roofing and HVAC applications, as well as for expansion joints.

3. Medical Equipment The comfort and flexibility of neoprene sheets make them ideal for protective gear, supports, and other medical equipment requiring durability and resistance to bodily fluids.

4. Sporting Goods Neoprene is widely used in wetsuits, knee braces, and other athletic gear, which benefits from its flexibility, durability, and thermal insulative properties.

5. Industrial Applications In manufacturing, neoprene sheets are utilized in conveyor belts, flooring, and protective mats, ensuring safety and efficiency.

Conclusion

In summary, 1% 208% neoprene rubber sheets are a crucial material that combines various beneficial properties to serve a wide range of industries. Their impressive chemical resistance, durability, flexibility, and weatherproof qualities make them ideal for applications from automotive to medical fields. As industries continue to evolve and demand high-performance materials, neoprene rubber sheets remain indispensable, showcasing the innovation and reliability of synthetic elastomers in modern manufacturing and engineering.

Next:

Prev: