Automotive sealing strips are important components of automobiles, widely used in areas such as doors, windows, body, seats, sunroof, engine compartment, and trunk. They play an important role in waterproofing, sealing, sound insulation, dust prevention, antifreeze, shock absorption, warmth preservation, and energy conservation. It must have strong tensile strength, good elasticity, as well as good temperature resistance and aging resistance. In order to ensure the fastening of the adhesive strip and the profile, the cross-sectional structure size of the adhesive strip must match the profile.

Classification and characteristics of automotive sealing strips:

Classified according to the composite structure of rubber materials, it can be divided into pure rubber sealing strips - composed of a single type of rubber; Two composite sealing strips - composed of dense adhesive and foam sponge adhesive, often containing metal skeleton materials in the axial direction inside the dense adhesive; Three composite sealing strips - composed of two types of dense adhesive (one of which is light colored) and sponge adhesive, usually containing a metal skeleton and reinforcing fibers inside the dense adhesive. Four composite sealing strips - Our company is the first in China to develop and produce a composite sealing strip composed of four types of adhesive materials. A thin protective layer of adhesive is coated on the surface of the sponge rubber (foam tube), further improving the service life of the sealing element.

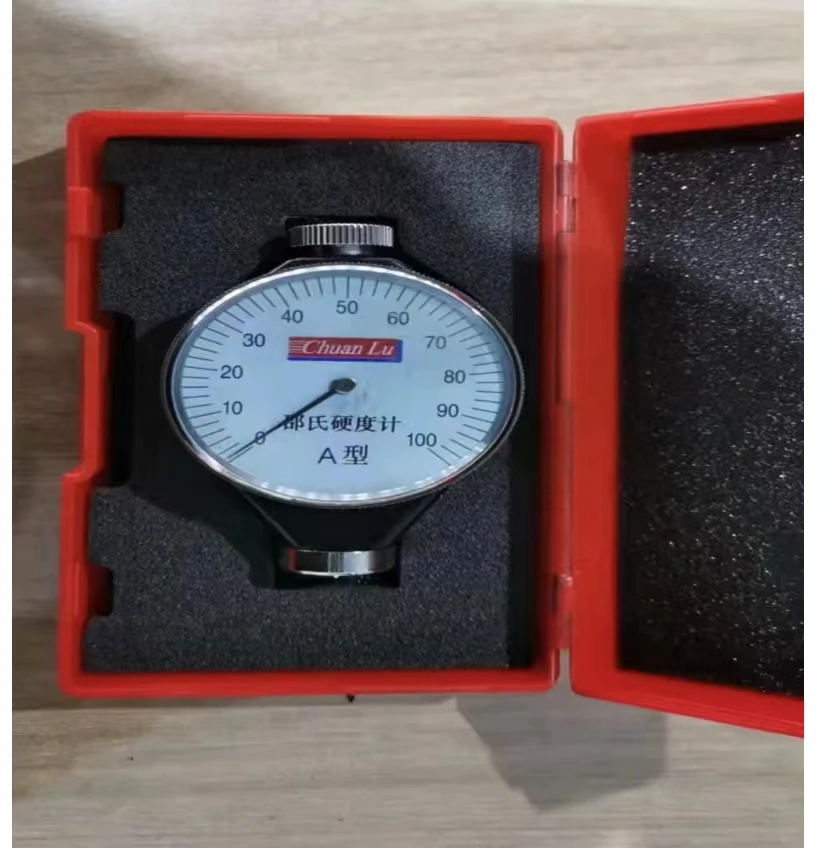

Automotive sealing strips are mainly made of EPDM rubber with good elasticity and resistance to compression deformation, aging, ozone, chemical action, and a wide temperature range of -40 ℃~+120 ℃, which is foamed and densely compounded. It contains unique metal fixtures and tongue shaped buckles, which are sturdy and durable, and easy to install. Suggested temperature range: PVC material -20 ° F -150 ° F (-29 ℃ -65.5 ℃) EPDM material -40 ° F -248 ° F (-40 ℃ -120 ℃) Internal metal fixture material: steel wire or sheet

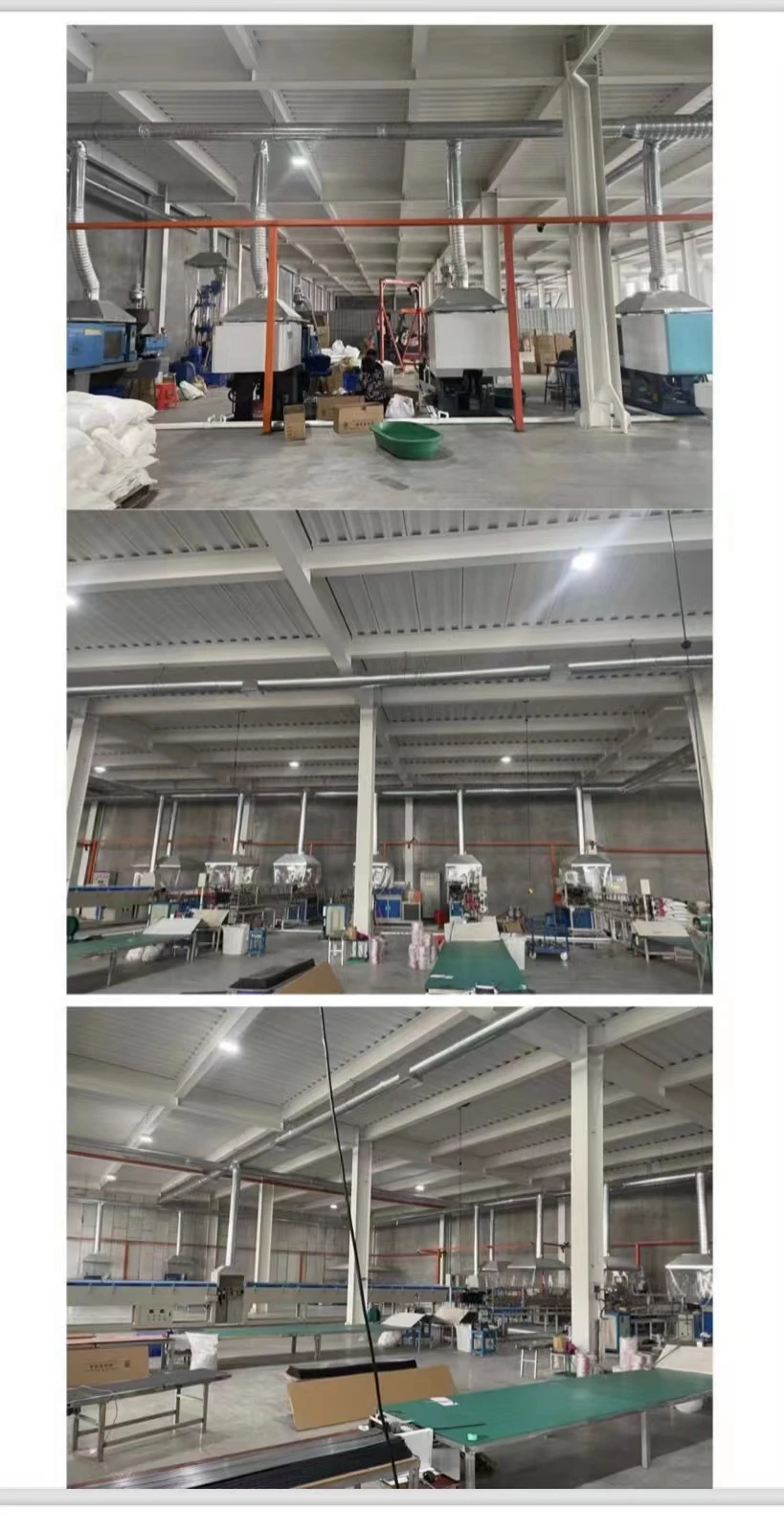

Hebei Zhouge Plastic Technology Co., Ltd. was established in 2014 and is committed to providing one-stop protection for fire prevention, smoke prevention, sound insulation, ventilation and sealing. By implementing this strategy, we have achieved a leading advantage. Firstly, provide cost-effective and reliable products for customers; Secondly, by integrating different product solutions to meet customer needs; Third, provide customers with one-stop, differentiated quality services, including detailed design, material solution consulting, supply chain management, quality control and financial support; Finally, always maintain innovation in technology and management.