Apr . 08, 2023 18:10 Back to list

Advantages and Disadvantages of PVC/EPDM/TPV/TPE Automotive Sealing Strip Materials

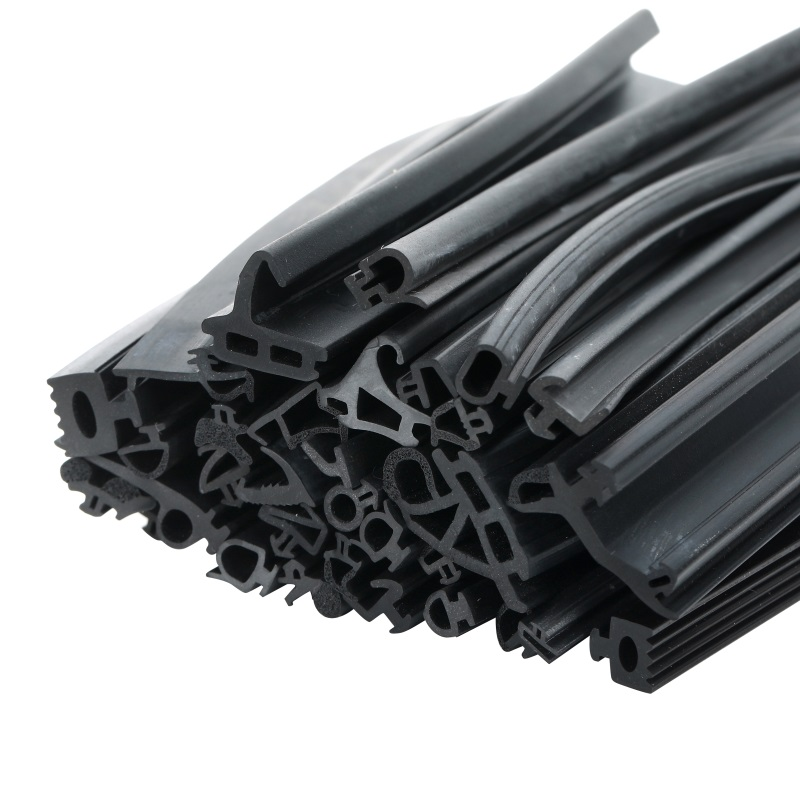

A sealing strip is a product that seals something to prevent it from being easily opened, providing shock absorption, waterproofing, sound insulation, insulation, dust prevention, and fixation. With the development of the automotive industry, the importance of beautiful, environmentally friendly, and comfortable functions of sealing strips is becoming increasingly prominent, and the demand for automotive sealing strip materials is also increasing. What kind of sealing strip material is good? Each sealing strip manufacturer has their own rhetoric. The current automotive sealing strip materials mainly include four types: PVC sealing strip, EPDM sealing strip, TPV sealing strip, and TPE sealing strip. Below, we will analyze the advantages and disadvantages of these four automotive sealing strip materials.

- PVC automotive sealing strip material

1、 Advantages of PVC sealing strip material

- Good processing performance;

- Low manufacturing cost;

- It has good characteristics such as corrosion resistance and insulation.

2、 Disadvantages of PVC sealing strip material

- The flow characteristics are quite poor, and the process range is very narrow;

- Some toxic additives and plasticizers in PVC may seep out or vaporize; Some may increase the risk of cancer; Incineration of PVC waste can produce carcinogenic dioxins that pollute the atmosphere.

- During combustion, a large amount of thick smoke will occur and harmful HCL gas will be generated; Moreover, most PVC materials contain various harmful heavy metals such as Pb (lead) and Cd (cadmium) (used as cable stabilizers), which can pose certain risks to human health; Burning or burying can cause pollution to soil and water sources.

- Not resistant to low temperatures, will become hard and brittle in winter, and the sealing effect will deteriorate; In summer, high temperatures will soften and the sealing effect will deteriorate.

- EPDM automotive sealing strip material

1、 Advantages of EPDM sealing strip material

- Good low-temperature performance, can reach -60 ℃ and maintain elasticity;

- High temperature resistance, continuous working temperature can reach above 110 ℃;

- It is resistant to chemical media such as brake fluid, water, coolant, detergent, strong alkali, etc;

- Excellent aging resistance, ozone resistance, and weather resistance, with a service life of over 10 years.

2、 Disadvantages of EPDM sealing strip material

- The price is slightly expensive;

- Difficulty in welding;

- Single color, usually black;

- Poor adhesion;

- The rubber sealing strip has a peculiar odor after vulcanization process, and cannot be recycled or degraded, resulting in high environmental pressure

- TPV automobile sealing strip material

1、 Advantages of TPV sealing strip material

- High temperature resistance: no deformation at 100 ℃, low temperature resistance, no hardness at -40 ℃;

- Small compression deformation can ensure good sealing effect;

- Good weather resistance and long-term use;

- It is oil resistant, has a small odor, can pass VOC testing, is matte, delicate, has a good hand feel, and has good anti-static performance, and is not contaminated with dust;

- Simple equipment, easy processing, high production efficiency, and low production cost;

- Small specific gravity (only 0.9-0.95); It seems that the procurement unit price is high, but the actual usage cost is low;

- Recyclable, free of heavy metals such as halogens and lead, and recyclable after several years, meeting the requirements for green building materials;

- The performance and service life are equivalent to those of vulcanized EPDM rubber sealing strips;

- The processing energy consumption is relatively low compared to vulcanized EPDM rubber strips (equivalent to PVC).

2、 Disadvantages of TPV sealing strip material

Moderate level compression will cause permanent deformation

- TPE automotive sealing strip material

1、 Advantages of TPE sealing strip material

- Low temperature resistance -30 ℃, high temperature 70 ℃, reduced compression type, good sealing effect, and good weather resistance;

- No odor, plasticizer, and harmful substances such as halogens, heavy metals, plasticizers, etc;

- High production efficiency, cheap equipment, and production speed several times faster than rubber;

- No cracking after ten years of outdoor use, with good sealing effect;

- It can be recycled, but it requires high on-site management requirements. The recycled materials should not contain other impurities, and the addition ratio should not exceed 20%.

2、 Disadvantages of TPE sealing strip material

For softer TPE, the compression set, high temperature resistance, solvent resistance, and oil resistance at higher temperatures are not as good as traditional vulcanized rubber.

Based on the above comparison, the most suitable order for making automotive sealing strips is TPE>TPV>EPDM>PVC

- PVC sealing strips have a small temperature range, are not environmentally friendly, and have a significant impact on human health. Developed countries abroad, as well as Beijing and first tier coastal cities in China, have explicitly restricted the use of PVC sealing strips. The use of PVC sealing strips will gradually decrease, especially in high-end industries.

- Silicone rubber sealing strip has good weather resistance and low temperature resistance, but its tear strength is low and the price is the highest, and its application field is limited.

- EPDM sealing strips have excellent performance in various aspects, but their prices are relatively high, their colors are single, and their processing is complex. They are only suitable for dynamic sealing situations where frequent switch actions occur.

Compared with EPDM sealing strips, TPV sealing strips have relatively lower prices and little difference in performance, indicating a promising future for use.

- TPE sealing strips not only have the excellent engineering performance of elastomers, but also have the excellent characteristics of plastics, which are convenient for processing and can be recycled and reused; Therefore, it is popular in static door and window sealing, exterior decorative layer of car sealing strips, insulation layer of wires, car switches, handles, and other aspects.

Next:

Prev: