Sep . 06, 2024 04:12 Back to list

High-Quality Aluminum Alloy Door and Window Rubber Seal Strips | Durable & Custom Solutions

Understanding Aluminum Alloy Door and Window Rubber Seal Strip Companies

In the modern construction and manufacturing industry, aluminum alloy door and window systems have gained immense popularity due to their strength, durability, and aesthetic appeal. A crucial component of these systems is the rubber seal strip, which plays a vital role in enhancing performance, energy efficiency, and comfort in residential and commercial spaces. This article explores the significance of rubber seal strips in aluminum alloy doors and windows and the companies that specialize in producing high-quality sealing solutions.

Rubber seal strips are designed to fill the gaps between the door or window frame and its opening, effectively preventing air and water infiltration. This not only helps in maintaining a stable interior environment but also reduces energy costs by minimizing the loss of conditioned air. In addition to energy efficiency, these seals contribute to improved acoustics by mitigating external noise, making them an essential feature for comfort in urban settings.

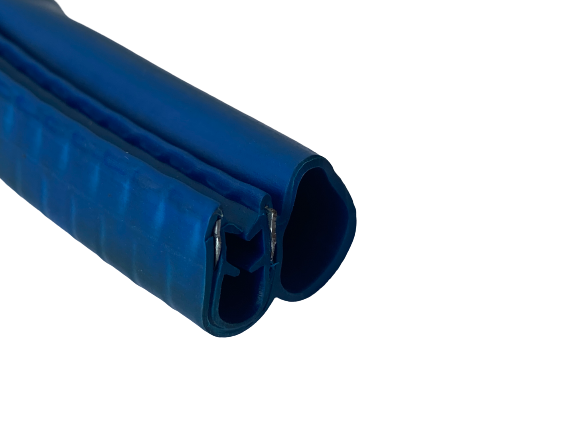

Companies that manufacture aluminum alloy door and window rubber seal strips focus on using innovative materials and advanced technology to produce seals that withstand extreme weather conditions and prolonged exposure to UV rays. The materials commonly used include EPDM (Ethylene Propylene Diene Monomer), PVC (Polyvinyl Chloride), and silicone, each offering unique benefits in terms of resilience, flexibility, and resistance to wear and tear.

aluminum alloy door and window rubber seal strip companies

Leading companies in this sector are committed to quality assurance, adhering to international standards and regulations. They often invest in research and development to create new formulations and designs that improve the performance and longevity of rubber seals. This focus on innovation allows manufacturers to cater to a diverse range of applications, from residential windows and doors to large-scale commercial installations.

The production process for rubber seal strips typically involves extrusion and molding techniques. These processes enable manufacturers to create custom profiles tailored to specific door and window designs. As a result, clients have the option to choose seals that best fit their needs, enhancing the overall effectiveness of their aluminum alloy systems.

In recent years, the demand for energy-efficient building solutions has surged, leading to a corresponding growth in the rubber seal strip market. Companies are now emphasizing sustainability, employing eco-friendly materials and processes that reduce environmental impact. This trend aligns with global efforts toward green building practices, making the choice of seal strips not only a functional decision but also a responsible one.

In conclusion, the role of aluminum alloy door and window rubber seal strip companies is integral to the construction and manufacturing ecosystem. Their commitment to quality, innovation, and sustainability ensures that end-users benefit from superior products that enhance energy efficiency and comfort in their living and working spaces. As the industry continues to evolve, these companies are well-positioned to meet the increasing demands for high-performance sealing solutions.