Oct . 17, 2024 05:57 Back to list

aluminum alloy door and window rubber seal strip factory

The Importance of Aluminum Alloy Door and Window Rubber Seal Strips in Modern Construction

In the modern construction landscape, the significance of high-quality materials cannot be overstated. Among these materials, aluminum alloys have gained immense popularity, especially in the manufacturing of door and window frames. However, to ensure durability, energy efficiency, and weather resistance, the inclusion of rubber seal strips becomes indispensable. This article delves into the importance of aluminum alloy door and window rubber seal strips, particularly emphasizing their manufacturing processes, benefits, applications, and the evolving technology within this field.

Understanding Aluminum Alloy in Architecture

Aluminum alloys possess an excellent strength-to-weight ratio, making them ideal for constructing durable door and window systems. They are resistant to corrosion, lightweight, and contribute to the overall energy efficiency of buildings. However, while aluminum frames provide an excellent structural foundation, they are not entirely sufficient for weatherproofing and insulation. This is where rubber seal strips come into play.

The Role of Rubber Seal Strips

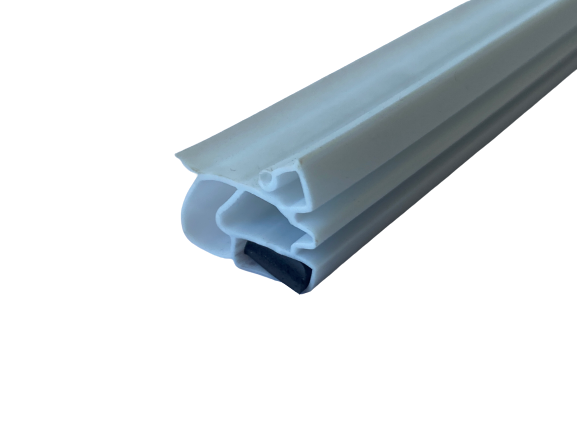

Rubber seal strips serve as the crucial interface between the aluminum frame and the external environment. They are designed to fill gaps between door and window frames and their corresponding surfaces, preventing air and water infiltration while enhancing thermal insulation. The performance of these rubber seals significantly affects the comfort and energy consumption of a building.

When properly installed, rubber seals can reduce heating and cooling costs by minimizing drafts and heat loss. This makes them an essential component in energy-efficient homes and buildings, especially in regions with extreme weather conditions.

Manufacturing Process of Rubber Seal Strips

The production of rubber seal strips involves several stages, starting from selecting the right type of rubber material. Common choices include EPDM (ethylene propylene diene monomer), silicone, and neoprene, all known for their flexibility, durability, and resistance to weathering.

The manufacturing process typically includes

1. Compounding Raw rubber is mixed with various additives to enhance its properties, such as UV resistance, longevity, and elasticity.

2. Molding The compounded rubber is then molded into specific shapes. This stage can involve extrusion to create continuous lengths of seal strips or compression molding for specific profiles.

3. Curing After molding, the rubber undergoes a curing process, which involves heating it to create cross-links between the rubber molecules. This process solidifies the material, enhancing its durability and performance.

aluminum alloy door and window rubber seal strip factory

4. Quality Control Rigorous testing is conducted to ensure that the seal strips meet industry standards. Parameters like tensile strength, elongation, and resistance to aging are assessed.

5. Surface Treatment Often, the finished products receive a surface treatment to improve their adhesion properties and overall appearance.

Benefits of Using High-Quality Rubber Seal Strips

1. Enhanced Energy Efficiency As mentioned, rubber seal strips play a pivotal role in minimizing energy loss, leading to lower utility bills and a reduced carbon footprint.

2. Weather Resistance High-quality rubber seals effectively repel water and prevent moisture from entering, protecting the structural integrity of buildings.

3. Noise Reduction The vibration-damping properties of rubber help reduce noise penetration, creating a quieter indoor environment.

4. Improved Aesthetics Available in various colors and designs, rubber seal strips can complement the aesthetics of modern architecture, adding to the visual appeal of doors and windows.

5. Longevity and Low Maintenance Properly manufactured seal strips are designed to withstand harsh environmental conditions, ensuring long-term performance with minimal maintenance required.

The Future of Rubber Seal Technology

As the demand for sustainable and energy-efficient building solutions continues to rise, manufacturers are innovating in the field of rubber seal technology. Developments include the incorporation of recycled materials into seal production and the implementation of advanced manufacturing processes that reduce waste and enhance product quality.

Conclusion

In summary, aluminum alloy door and window rubber seal strips are integral to modern construction, enhancing energy efficiency, weather resistance, and overall performance of building envelopes. Their production involves meticulous processes that ensure high quality and durability, contributing to the longevity and functionality of architectural applications. As technology continues to evolve, the future of rubber seals promises to address sustainability challenges while meeting the growing demands of the construction industry. Investing in quality seal strips is not just a construction choice; it's a commitment to building a more energy-efficient and resilient future.

Next:

Prev: