Oct . 11, 2024 02:06 Back to list

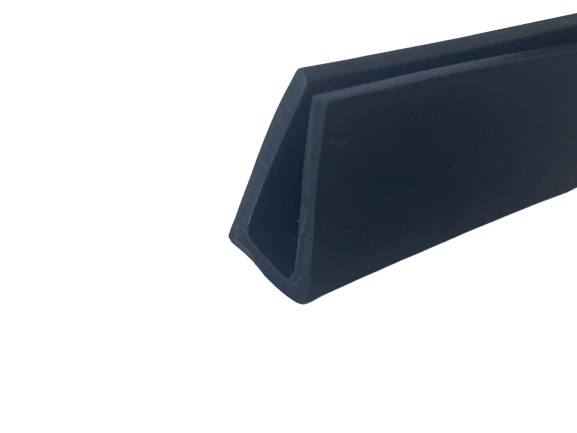

Anti-collision Rubber Seals for Marine Vessels in Type D Configuration

Anti-Collision Rubber Seal for Ships Enhancing Marine Safety and Efficiency

In the maritime industry, safety is paramount. With vessels operating in busy ports and exposed to harsh maritime conditions, the need for effective collision prevention becomes crucial. One innovative solution that has gained significant attention is the anti-collision rubber seal, particularly in ship type D designs. This technology not only protects ships but also enhances overall operational efficiency in marine environments.

What is an Anti-Collision Rubber Seal?

An anti-collision rubber seal is a protective barrier made of high-quality rubber, designed to absorb impacts during docking or mooring. Unlike traditional fenders that only provide a cushioning effect, these seals are engineered to withstand significant forces, thereby minimizing damage to both the vessel and the docking infrastructure. The seal is typically affixed to the sides of the ship, fenders, or docks, where they can effectively manage the impact dynamics between vessels and fixed structures.

Importance in Ship Type D

Ship type D vessels, characterized by their larger hull dimensions and higher operational speeds, are particularly susceptible to impact damage during docking. The anti-collision rubber seal plays a vital role in mitigating these risks. With its robust construction and elasticity, the seal can absorb the kinetic energy generated upon impact, reducing the stress transferred to the ship’s hull and the docking infrastructure. This not only prevents property damage but also minimizes injuries to crew members and port workers.

Benefits of Anti-Collision Rubber Seals

anti-collision rubber seal for ship type d

1. Impact Absorption The primary benefit of anti-collision rubber seals is their ability to absorb impacts. When a vessel comes into contact with a dock or another ship, the rubber seal compresses, redistributing the energy and lessening the severity of the collision.

2. Durability Crafted from high-quality rubber compounds, these seals are durable and weather-resistant. They can withstand the elements, including UV radiation, saltwater, and extreme temperatures, ensuring long-term functionality with minimal maintenance.

3. Cost-Effectiveness While the initial investment in anti-collision rubber seals might be higher than traditional protection methods, the long-term savings are significant. By preventing damage to the ship and dock, these seals reduce repair costs and downtime, making them a cost-effective solution for marine operations.

4. Improved Docking Efficiency With the installation of anti-collision seals, vessels can dock with a higher degree of confidence, leading to quicker turnarounds. This efficiency can result in increased throughput for ports and reduced waiting times for vessels, ultimately enhancing economic productivity.

5. Environmental Considerations The use of anti-collision rubber seals also has positive environmental impacts. By preventing spills and accidents caused by collisions, these seals contribute to the protection of marine ecosystems and reduce the risk of pollution from damaged vessels.

Conclusion

As the maritime industry continues to evolve, the need for advanced safety measures becomes increasingly important. The anti-collision rubber seal represents a significant step forward in protecting vessels, crew, and infrastructure from the risks associated with maritime operations. For ship type D vessels, in particular, these seals offer unparalleled defense against collision impacts while promoting operational efficiency and environmental protection. As shipbuilders, port managers, and maritime operators recognize the value of investing in such innovative technologies, we can expect to see a stronger emphasis on safety and sustainability in the industry. The adoption of anti-collision rubber seals is not just an enhancement; it is becoming a standard for modern maritime operations, ensuring a safer future for all.

Next:

Prev: