Dec . 04, 2024 16:29 Back to list

best epdm rubber sheet

The Best EPDM Rubber Sheets A Comprehensive Overview

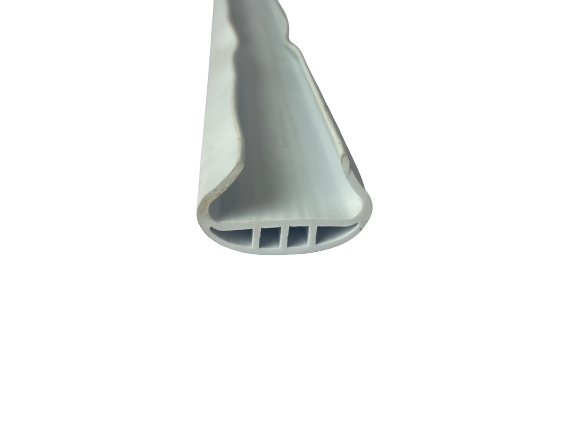

EPDM (Ethylene Propylene Diene Monomer) rubber sheets have become a staple in various industries due to their superior properties and versatility. These sheets are made from a type of synthetic rubber that offers excellent resistance to weathering, ozone, and UV radiation. With a unique composition that includes ethylene and propylene, EPDM rubber provides outstanding performance in extreme conditions. In this article, we will explore the best EPDM rubber sheets available in the market, their applications, and the benefits they offer.

Exceptional Weather Resistance

One of the most significant advantages of EPDM rubber is its exceptional weather resistance. Unlike natural rubber, EPDM does not break down when exposed to sunlight, making it ideal for outdoor applications. The material can withstand UV rays, oxygen, and ozone, which are notorious for deteriorating other types of rubber. Because of this resilience, EPDM rubber sheets are commonly used in roofing systems, automotive parts, and outdoor seals.

Versatility in Applications

EPDM rubber sheets are known for their versatility, making them suitable for a wide range of applications across various sectors

1. Construction Industry EPDM sheets are widely used in roofing systems, where they provide an excellent waterproof barrier. They are also utilized in expansion joints, seals, and gaskets to ensure structural integrity in buildings.

2. Automotive Industry The automotive sector benefits from EPDM rubber's durability, using it in weather stripping, seals, and hoses to ensure vehicles remain weatherproof and reliable over time.

3. Manufacturing Sector EPDM sheets are often employed in various manufacturing processes, such as conveyor belts and mats, where resilience and resistance to abrasion are essential.

4. Electrical Insulation EPDM’s excellent dielectric properties make it an excellent choice for electrical insulation components in various devices and machines.

Superior Chemical Resistance

EPDM rubber sheets also exhibit superior resistance to many chemicals, including acids, bases, and other corrosive substances. This makes them suitable for use in environments where exposure to harsh chemicals is common, such as in chemical processing industries. Their ability to maintain integrity in hostile environments is crucial for minimizing downtime and maintaining operational efficiency.

best epdm rubber sheet

Thermal Stability

Another impressive feature of EPDM rubber sheets is their thermal stability. They can endure a wide temperature range—from -40°F to 212°F (-40°C to 100°C)—without losing their physical properties. This capability allows them to be used in applications involving exposure to heat or cold, ensuring consistent performance regardless of environmental conditions.

Eco-Friendly Option

As concerns about environmental sustainability grow, EPDM rubber stands out as an eco-friendly option. Unlike many synthetic materials, EPDM can be recycled, and its production involves relatively lower energy consumption. By choosing EPDM rubber sheets, companies can reduce their environmental footprint while benefiting from high-quality materials.

Factors to Consider When Choosing EPDM Rubber Sheets

When selecting EPDM rubber sheets, it's essential to consider a few key factors

1. Thickness The thickness of the rubber sheet can affect its performance in specific applications. Thicker sheets may provide better durability, while thinner sheets can be easier to work with in applications requiring flexibility.

2. Hardness EPDM rubber hardness is measured on the Shore A scale. Depending on the application, you may need harder or softer rubber to meet specific functional requirements.

3. Color and Finish EPDM sheets come in various colors and finishes to suit different aesthetic and functional needs. Depending on your project, you may prefer a specific color or surface texture.

4. Certifications Ensure that the EPDM rubber sheets come with relevant industry certifications, indicating they meet specific quality and safety standards.

Conclusion

In summary, EPDM rubber sheets are an exceptional material characterized by their outstanding durability, weather resistance, and versatility. Their applications across multiple industries highlight their importance in modern manufacturing, construction, and automotive sectors. By choosing the right EPDM rubber sheets, businesses can ensure they receive a reliable product that meets their specific needs, thereby enhancing operational efficiency and longevity. As the demand for reliable and eco-friendly materials continues to rise, EPDM will undoubtedly remain a top choice for many industries.