Nov . 06, 2024 17:00 Back to list

Durable Black Neoprene Rubber Sheet for Versatile Applications and Custom Solutions

The Versatility of Black Neoprene Rubber Sheets

Black neoprene rubber sheets have become an indispensable material in various industries due to their unique properties and wide range of applications. Neoprene, also known as polychloroprene, is a synthetic rubber that was developed in the 1930s. Since then, it has found its way into numerous products and applications, making it a popular choice for both commercial and industrial uses.

One of the most prominent features of black neoprene rubber sheets is their excellent resistance to temperature fluctuations. They can withstand extreme temperatures, ranging from -40°F to 160°F (-40°C to 70°C), without losing their structural integrity. This thermal stability makes neoprene very suitable for applications that involve exposure to high heat or cold environments.

In addition to temperature resistance, black neoprene rubber sheets boast remarkable chemical resistance

. They can withstand exposure to oils, gasoline, and various solvents, making them ideal for use in automotive, aerospace, and industrial applications where chemical exposure is an everyday concern. This characteristic not only extends the life of the products made from neoprene but also ensures safety and reliability.Another significant advantage of black neoprene rubber sheets is their excellent weather resistance. These sheets are designed to withstand the rigors of outdoor conditions, including UV rays, ozone, and moisture. This feature makes them particularly useful in construction, marine, and outdoor applications, where materials are often subjected to varying environmental conditions.

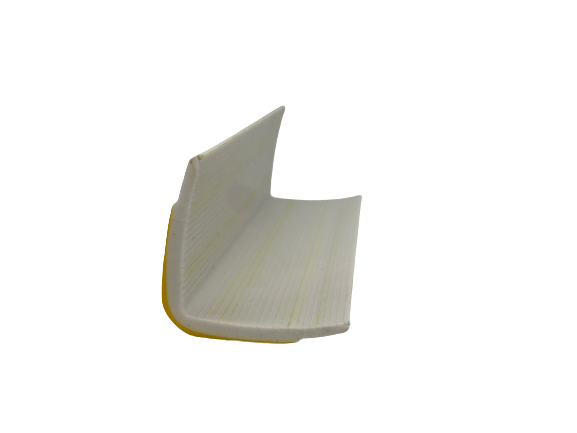

black neoprene rubber sheet

Thickness and density are key features of neoprene rubber sheets, and they come in various sizes catering to different needs. Thicker sheets offer more cushioning, making them perfect for applications such as gaskets, seals, and soundproofing materials where absorbing impact and noise is essential. Conversely, thinner sheets can be used in applications requiring flexibility and ease of handling, such as in clothing, footwear, and accessories.

Moreover, the non-porous nature of neoprene rubber sheets means they do not absorb water, making them ideal for products meant for wet environments. For instance, neoprene is commonly used in the production of wetsuits, diving gear, and other water sports equipment. The material provides thermal insulation and buoyancy, allowing for better performance in aquatic activities.

In the realm of manufacturing, black neoprene rubber sheets are easily cut, shaped, and molded, allowing for high versatility in design and application. Industries often use custom-cut neoprene sheets for specialized applications, such as custom gaskets, seals, and pads, which require precise dimensions and specifications.

The environmental aspect is also worth noting. Neoprene is a synthetic product, but advancements in technology have led to the development of eco-friendly neoprene alternatives. These sustainable materials help reduce the overall carbon footprint of the products made from neoprene.

In conclusion, black neoprene rubber sheets offer a unique combination of properties that make them invaluable in various industries. Their exceptional resistance to temperature, chemicals, and weather, coupled with their ease of handling and customization, ensure that they meet the demands of diverse applications. As industries continue to innovate and seek durable materials, the role of black neoprene rubber sheets will undoubtedly grow, solidifying their status as a fundamental component in countless products. Whether for industrial use or consumer goods, neoprene remains a trusted material that delivers performance and reliability.

Next:

Prev: