Aug . 22, 2024 01:43 Back to list

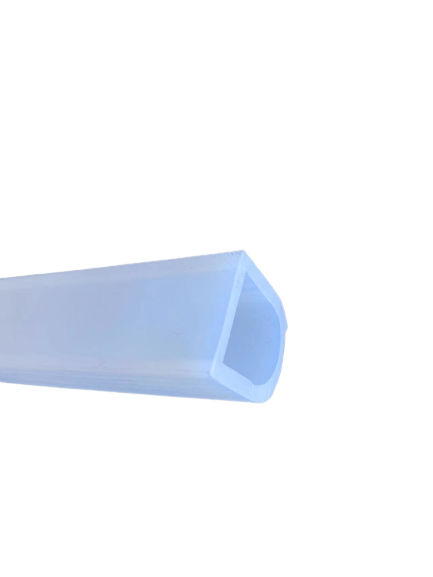

Bottom Rubber Seal for Overhead Doors to Enhance Insulation and Weatherproofing

The Importance of Overhead Door Bottom Rubber Seals

Overhead doors are essential components in warehouses, garages, and various commercial facilities, providing both security and accessibility. However, the efficiency and longevity of these doors can be significantly affected by their components, particularly the bottom rubber seal. This seemingly minor detail plays a pivotal role in the overall functionality of overhead doors.

Functionality and Benefits

The primary function of an overhead door bottom rubber seal is to create a tight barrier between the door's bottom edge and the ground

. This seal prevents drafts, dust, and debris from entering the building, which is especially crucial in industrial settings. By ensuring a proper seal, businesses can maintain better control over their internal environment, contributing to energy efficiency. This is particularly important in regions with extreme weather conditions, as it helps regulate indoor temperatures, reducing heating and cooling costs.Additionally, a high-quality bottom rubber seal provides protection against water intrusion. In environments prone to rain or flooding, having a reliable seal can minimize the risk of water damage, safeguarding equipment and inventory stored in the facility. This protective barrier can extend the lifespan of the overhead door itself by preventing moisture-related issues that could lead to rust or corrosion.

Choosing the Right Seal

When selecting a bottom rubber seal for an overhead door, several factors should be considered. The material of the seal is critical; high-grade rubber is often preferred for its durability and resistance to various environmental conditions. Additionally, the size and profile of the seal must be compatible with the specific overhead door model to ensure optimal performance.

overhead door bottom rubber seal

Installation plays an equally important role. Properly fitting the seal ensures that gaps are minimized; any misalignment can lead to compromised sealing effectiveness. Many seals are designed for easy installation, featuring adhesive backing or straightforward mounting systems, making it accessible for business owners to replace or upgrade their seals without professional assistance.

Maintenance and Longevity

To maximize the lifespan of the bottom rubber seal, regular maintenance is essential. This includes periodic inspections to check for signs of wear, such as cracking or tearing. Environmental factors like extreme temperatures and UV exposure can degrade rubber over time, making it vital to replace seals as needed.

Additionally, keeping the area around the seal free from debris and obstructions can enhance its performance. This not only aids in providing a tighter seal but also contributes to the overall functionality of the overhead door system. An overlooked yet crucial aspect of maintenance is cleaning the seal itself; dirt and grime can accumulate and hinder its effectiveness, so regular cleaning with mild soap and water is recommended.

Conclusion

In conclusion, the bottom rubber seal of overhead doors plays a significant role in ensuring the efficiency, safety, and longevity of the door itself. Investing in high-quality seals and performing routine maintenance can lead to substantial savings in energy costs and prevent costly repairs due to water damage or wear and tear. As the backbone of operational efficiency in many facilities, the bottom rubber seal should not be overlooked. By giving this small yet significant component the attention it deserves, businesses can enhance their overall operations and maintain a safe, protected environment. Whether you manage a large warehouse or a small garage, ensuring that your overhead doors are equipped with the right bottom rubber seal is key to long-term success.