Jun . 14, 2024 11:25 Back to list

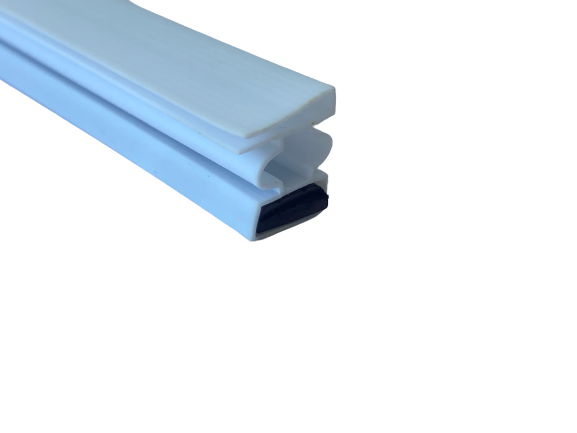

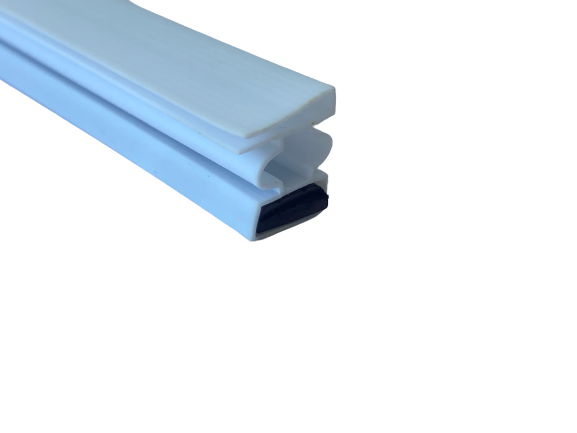

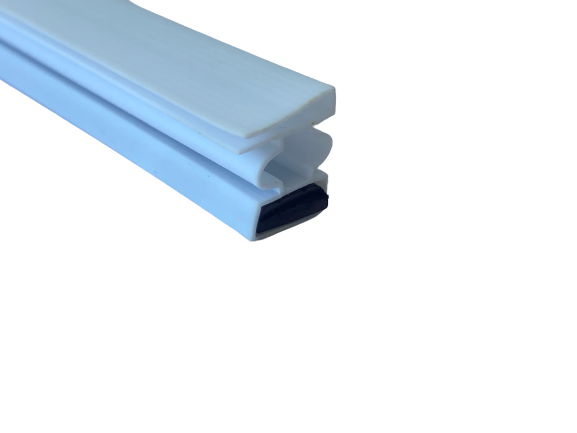

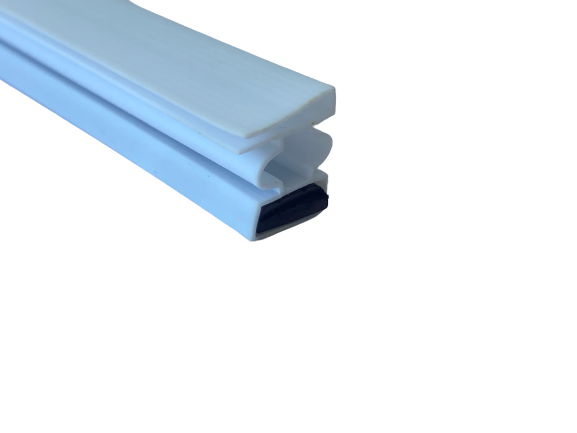

Butyl rubber rolls are durable and versatile.

The Versatile World of Butyl Rubber Rolls

Butyl rubber rolls have become an essential component in a variety of industries, from automotive manufacturing to construction and even in the realm of art and design. This unique material offers a range of properties that make it ideal for an array of applications, including its exceptional resistance to weathering, chemicals, and temperature extremes.

The chemical composition of butyl rubber is primarily responsible for its impressive characteristics. Developed in the mid-20th century, butyl rubber is a copolymer made up of isobutylene and small amounts of isoprene. This unique blend gives butyl rubber its low permeability to gases, making it an excellent sealant. It also endows the material with high resistance to moisture, ozone, and various chemicals. Furthermore, the molecular structure of butyl rubber provides it with remarkable elasticity and shock absorption capabilities.

In the automotive industry, butyl rubber rolls are often used as seals around windows and doors to prevent water and air leaks. They are also used in the production of tire inner tubes due to their puncture resistance and ability to retain air. The construction industry utilizes butyl rubber rolls for waterproofing and sealing roofs, gutters, and other structures prone to water damage. The durability of these rolls ensures long-lasting protection against the elements The durability of these rolls ensures long-lasting protection against the elements The durability of these rolls ensures long-lasting protection against the elements The durability of these rolls ensures long-lasting protection against the elements

The durability of these rolls ensures long-lasting protection against the elements The durability of these rolls ensures long-lasting protection against the elements butyl rubber rolls.

Artists and designers have also found a use for butyl rubber rolls in creative projects. Its malleability allows for the formation of intricate shapes and patterns, while its color stability ensures that artworks remain vibrant over time, despite exposure to sunlight or other harsh environmental conditions.

Despite its numerous benefits, butyl rubber is not without its challenges. The material can be difficult to bond with other types of rubber or with certain adhesives, requiring specialized techniques or formulations. Additionally, the cost of butyl rubber is generally higher than other rubber compounds, which can impact the budgetary considerations of some projects.

In conclusion, butyl rubber rolls stand as a testament to the innovative uses of synthetic materials in modern society. Their unique properties make them invaluable in industries where reliability and durability are paramount. As technology continues to advance, the potential applications for butyl rubber rolls are likely to expand, further solidifying their place in our industrial landscape.

butyl rubber rolls.

Artists and designers have also found a use for butyl rubber rolls in creative projects. Its malleability allows for the formation of intricate shapes and patterns, while its color stability ensures that artworks remain vibrant over time, despite exposure to sunlight or other harsh environmental conditions.

Despite its numerous benefits, butyl rubber is not without its challenges. The material can be difficult to bond with other types of rubber or with certain adhesives, requiring specialized techniques or formulations. Additionally, the cost of butyl rubber is generally higher than other rubber compounds, which can impact the budgetary considerations of some projects.

In conclusion, butyl rubber rolls stand as a testament to the innovative uses of synthetic materials in modern society. Their unique properties make them invaluable in industries where reliability and durability are paramount. As technology continues to advance, the potential applications for butyl rubber rolls are likely to expand, further solidifying their place in our industrial landscape.

The durability of these rolls ensures long-lasting protection against the elements The durability of these rolls ensures long-lasting protection against the elements

The durability of these rolls ensures long-lasting protection against the elements The durability of these rolls ensures long-lasting protection against the elements butyl rubber rolls.

Artists and designers have also found a use for butyl rubber rolls in creative projects. Its malleability allows for the formation of intricate shapes and patterns, while its color stability ensures that artworks remain vibrant over time, despite exposure to sunlight or other harsh environmental conditions.

Despite its numerous benefits, butyl rubber is not without its challenges. The material can be difficult to bond with other types of rubber or with certain adhesives, requiring specialized techniques or formulations. Additionally, the cost of butyl rubber is generally higher than other rubber compounds, which can impact the budgetary considerations of some projects.

In conclusion, butyl rubber rolls stand as a testament to the innovative uses of synthetic materials in modern society. Their unique properties make them invaluable in industries where reliability and durability are paramount. As technology continues to advance, the potential applications for butyl rubber rolls are likely to expand, further solidifying their place in our industrial landscape.

butyl rubber rolls.

Artists and designers have also found a use for butyl rubber rolls in creative projects. Its malleability allows for the formation of intricate shapes and patterns, while its color stability ensures that artworks remain vibrant over time, despite exposure to sunlight or other harsh environmental conditions.

Despite its numerous benefits, butyl rubber is not without its challenges. The material can be difficult to bond with other types of rubber or with certain adhesives, requiring specialized techniques or formulations. Additionally, the cost of butyl rubber is generally higher than other rubber compounds, which can impact the budgetary considerations of some projects.

In conclusion, butyl rubber rolls stand as a testament to the innovative uses of synthetic materials in modern society. Their unique properties make them invaluable in industries where reliability and durability are paramount. As technology continues to advance, the potential applications for butyl rubber rolls are likely to expand, further solidifying their place in our industrial landscape.