Mar . 06, 2025 11:52 Back to list

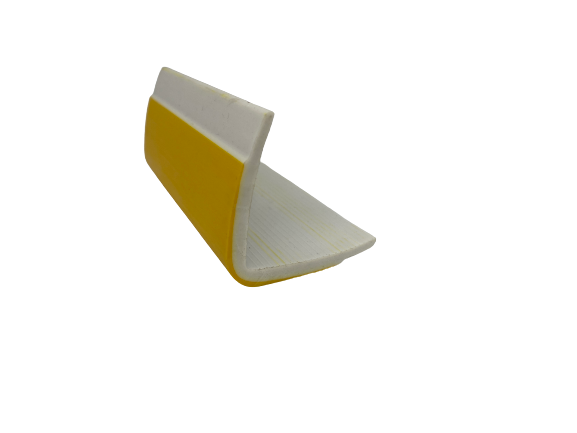

buy plastic steel door and window rubber sealing strip

Selecting the right rubber sealing strip for plastic steel doors and windows is crucial for ensuring durability, energy efficiency, and maintaining the integrity of your home or office environment. A high-quality sealing strip not only prevents drafts and water penetration but also enhances sound insulation, making your space more comfortable and energy-efficient.

Installation expertise plays a critical role in the effectiveness of sealing strips. Even the best-quality seals can underperform if not installed correctly. For optimal performance, it is advisable to seek professional assistance or thoroughly follow manufacturer guidelines if opting for a DIY approach. Proper alignment, surface cleaning, and correct pressure application are key factors in ensuring a tight seal, which in turn maximizes energy efficiency and weatherproofing. Maintenance should not be overlooked in prolonging the life and functionality of rubber sealing strips. Regular inspections for signs of wear, such as cracks or loss of elasticity, can help in identifying when replacements are necessary. Given the affordability of rubber sealing strips, periodic replacements are a cost-effective way to maintain optimal performance of your plastic steel doors and windows. Lastly, consider the aesthetic alignment of the sealing strip with your doors and windows. Although functional performance is paramount, a visually cohesive appearance contributes to the overall appeal of your property. Many sealing strips come in various colors and profiles to blend seamlessly with different design styles, enabling you to maintain both functionality and style. In conclusion, selecting the right rubber sealing strip for plastic steel doors and windows is crucial. By considering factors such as material type, certification, brand reputation, and professional installation, you can ensure your home or office is well-protected against the elements while providing a comfortable and energy-efficient environment. Regular maintenance further extends their lifespan, solidifying your investment in improving and preserving the quality and value of your property.

Installation expertise plays a critical role in the effectiveness of sealing strips. Even the best-quality seals can underperform if not installed correctly. For optimal performance, it is advisable to seek professional assistance or thoroughly follow manufacturer guidelines if opting for a DIY approach. Proper alignment, surface cleaning, and correct pressure application are key factors in ensuring a tight seal, which in turn maximizes energy efficiency and weatherproofing. Maintenance should not be overlooked in prolonging the life and functionality of rubber sealing strips. Regular inspections for signs of wear, such as cracks or loss of elasticity, can help in identifying when replacements are necessary. Given the affordability of rubber sealing strips, periodic replacements are a cost-effective way to maintain optimal performance of your plastic steel doors and windows. Lastly, consider the aesthetic alignment of the sealing strip with your doors and windows. Although functional performance is paramount, a visually cohesive appearance contributes to the overall appeal of your property. Many sealing strips come in various colors and profiles to blend seamlessly with different design styles, enabling you to maintain both functionality and style. In conclusion, selecting the right rubber sealing strip for plastic steel doors and windows is crucial. By considering factors such as material type, certification, brand reputation, and professional installation, you can ensure your home or office is well-protected against the elements while providing a comfortable and energy-efficient environment. Regular maintenance further extends their lifespan, solidifying your investment in improving and preserving the quality and value of your property.