Nov . 12, 2024 10:18 Back to list

car fuel tank gasket companies

The Importance of Fuel Tank Gaskets and the Leading Companies in the Industry

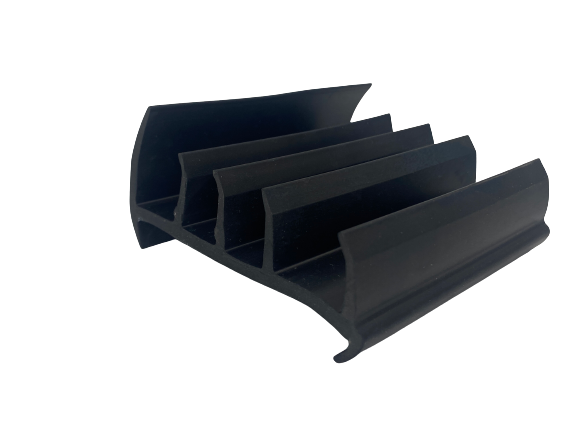

Fuel tank gaskets play a crucial role in the safe and efficient operation of vehicles. These small yet vital components are designed to seal the joints between the fuel tank and its filler neck, preventing fuel leaks and ensuring the integrity of the fuel system. This article explores the significance of fuel tank gaskets, common materials used in their production, and some of the leading companies in the gasket manufacturing industry.

Understanding Fuel Tank Gaskets

At first glance, a fuel tank gasket might seem minor in comparison to other vehicle components, but its importance cannot be overstated. A malfunctioning gasket can lead to serious issues, including fuel leaks, which pose safety hazards and environmental concerns. Fuel leaks can result in hazardous spills, fire risks, and increased emissions, making the reliability of gaskets critical. Their primary function is to provide a tight seal under varying temperature and pressure conditions, which can be challenging due to the volatile nature of fuel.

Moreover, fuel tank gaskets must withstand exposure to gasoline, diesel, and other fuel types, which can be corrosive and degrade materials over time. Therefore, the quality of gaskets directly impacts fuel efficiency and overall vehicle performance.

Materials Used in Fuel Tank Gasket Production

The materials used for fuel tank gaskets must be carefully selected to resist the chemical properties of fuels. Common materials include rubber, cork, and various synthetic compounds.

1. Rubber Ethylene Propylene Diene Monomer (EPDM) rubber is a popular choice due to its excellent resistance to heat, oxidation, and UV exposure, making it suitable for outdoor applications. Nitrile rubber is also widely used, especially in applications where oil and fuel resistance are crucial.

2. Cork Although cork gaskets have largely been replaced by synthetic materials in many applications, they still offer excellent sealing properties and flexibility. Cork is often used in older car models or specialty vehicles.

3. PTFE (Polytetrafluoroethylene) This synthetic material is known for its high resistance to chemicals and temperature, making it ideal for high-performance vehicles.

car fuel tank gasket companies

Leading Companies in Fuel Tank Gasket Manufacturing

Several companies are recognized for their innovation and quality in the gasket manufacturing industry. Here are some notable names

1. Fel-Pro A subsidiary of Federal-Mogul, Fel-Pro is a trusted manufacturer of gaskets and sealing solutions for the automotive aftermarket. They offer high-quality fuel tank gaskets that meet or exceed OEM specifications.

2. Victor Reinz Known for its premium sealing products, Victor Reinz manufactures a wide range of gaskets, including fuel tank gaskets. Their advanced engineering ensures reliability and durability, which are essential in today's automotive landscape.

3. Mahle This company provides a variety of engine components and sealing solutions. Mahle's fuel tank gaskets are designed with precision to ensure optimal performance and longevity.

4. Cometic Gasket Specializing in performance applications, Cometic Gasket manufactures high-performance gasket solutions for racing and custom vehicles. Their expertise in materials and engineering creates products that meet the demanding needs of automotive enthusiasts.

5. Gasket Masters This company focuses on providing custom gaskets, including fuel tank gaskets, made to fit specific vehicle models. Their commitment to quality and customer satisfaction sets them apart in the industry.

6. Permatex While known primarily for sealants and adhesives, Permatex also offers gasket-making products suitable for fuel applications. Their innovative solutions provide effective sealing for both professional mechanics and DIY enthusiasts.

Conclusion

Fuel tank gaskets may be small, but their significance is immense in the realm of automotive engineering. They are essential for maintaining fuel integrity, preventing leaks, and ensuring safety on the road. The choice of material and the expertise of the manufacturer play a vital role in the performance of these gaskets. As the automotive industry continues to evolve, with a growing focus on efficiency and eco-friendliness, the demand for high-quality fuel tank gaskets will also rise. By understanding the role of these components and the companies that produce them, consumers and industry professionals alike can make informed decisions that benefit both vehicle performance and environmental sustainability.