Nov . 08, 2024 23:04 Back to list

Automotive Window Rubber Seal Production and Supply Services for Quality Performance

Understanding Car Window Rubber Seal Manufacturers

The automotive industry has long relied on innovation and quality to ensure vehicles are both functional and comfortable. One essential component of any vehicle that often goes unnoticed is the rubber seal used around car windows. These seals play a crucial role in maintaining the integrity of the vehicle, providing insulation against noise, water, and debris. As such, car window rubber seal manufacturers are pivotal to the automotive supply chain, ensuring that vehicles meet consumer expectations for comfort and durability.

What Are Car Window Rubber Seals?

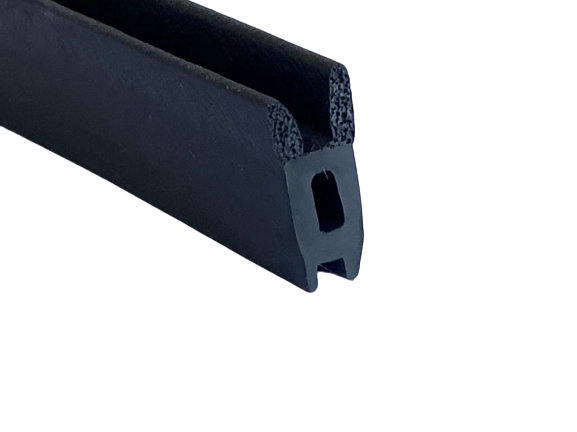

Car window rubber seals are typically made from high-quality rubber or synthetic materials designed to withstand varying weather conditions. These seals serve multiple purposes, including preventing water leakage during rain, reducing wind noise while driving, and providing insulation to enhance passenger comfort. They also serve to secure the window glass in place, ensuring that it does not rattle or shift while the vehicle is in motion.

The Role of Manufacturers

Car window rubber seal manufacturers specialize in producing these essential components. They usually employ advanced manufacturing techniques, ensuring every seal meets stringent quality standards set by the automotive industry. The production process often involves the following steps

1. Material Selection Manufacturers choose the appropriate rubber materials based on factors such as durability, flexibility, and resistance to environmental wear. Common choices include EPDM (Ethylene Propylene Diene Monomer), which provides excellent resistance to heat, ozone, and weathering.

2. Design and Molding Utilizing computer-aided design (CAD) software, manufacturers design seals to fit specific vehicle models. Custom molds are then created to shape the rubber into the desired profiles.

3. Testing Quality control is imperative. Manufacturers conduct rigorous testing to ensure that the seals meet performance standards. This includes testing for water resistance, temperature resilience, and overall durability over time.

car window rubber seal manufacturer

4. Distribution Once produced and tested, the seals are distributed to automotive manufacturers or aftermarket retailers, where they are used in both new vehicle production and as replacements.

Innovations in Seal Manufacturing

In recent years, the industry has seen significant innovations aimed at improving the performance and sustainability of rubber seals. Manufacturers are increasingly using recycled materials to produce eco-friendly seals without compromising quality. Additionally, advancements in manufacturing technologies, such as 3D printing, are allowing for more complex and efficient production processes.

Challenges Faced by Manufacturers

While there are many opportunities in the market, car window rubber seal manufacturers also face challenges. Competition from low-cost foreign manufacturers can put pressure on pricing and margins. Moreover, the shift towards electric and hybrid vehicles has led manufacturers to adapt and innovate their products to meet the unique requirements of这些 vehicles.

The Future of Car Window Rubber Seal Manufacturing

As the automotive industry evolves, so too will the demands on rubber seal manufacturers. The growing trend for enhanced vehicle aerodynamics and energy efficiency will likely lead to new designs and materials that improve performance. Additionally, as consumer awareness of environmental issues increases, manufacturers must prioritize sustainability in their production processes.

In conclusion, car window rubber seal manufacturers play a critical role in the automotive sector, contributing to vehicle safety, comfort, and efficiency. As technology advances and consumer expectations shift, these manufacturers will need to adapt, embracing innovation while maintaining high standards of quality and performance. Whether it’s producing seals for a new electric vehicle or providing replacement parts for older models, their contribution to the industry is invaluable and will continue to be a key focus as the automotive landscape evolves.