Aug . 07, 2024 15:55 Back to list

CE Certification for U Type EPDM Gaskets Designed for Automotive Fuel Tank Applications

CE Certification of U-Type EPDM Gaskets for Automobile Fuel Tanks

In the automotive industry, ensuring the reliability and safety of fuel systems is paramount. Among the critical components that contribute to this safety are gaskets, specifically the U-type EPDM (Ethylene Propylene Diene Monomer) gaskets used in fuel tanks. The CE certification of these gaskets plays a significant role in guaranteeing their quality and compliance with European safety standards, making them indispensable in modern automotive manufacturing.

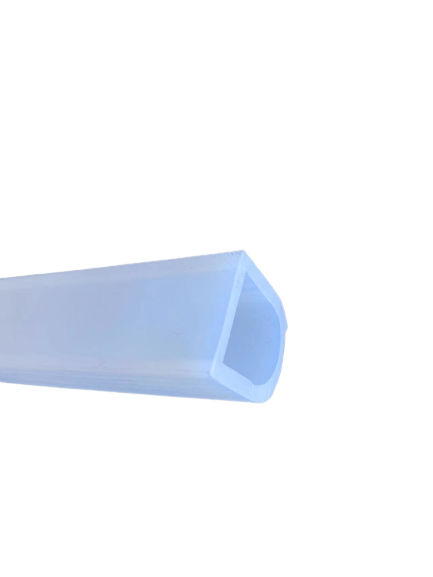

EPDM is a synthetic rubber that is well-regarded for its exceptional resistance to heat, oxidation, and various chemicals. These properties make it an ideal material for automotive applications, particularly in fuel tanks where exposure to fuel and fluctuating temperatures is a consistent concern. The U-type design of the gasket ensures a reliable seal, preventing fuel leakage and contributing to the overall integrity of the vehicle’s fuel system.

The CE marking, which stands for Conformité Européenne, indicates that a product meets the essential requirements of relevant European health, safety, and environmental protection legislation. For automotive parts, achieving CE certification involves rigorous testing and evaluation to ensure that the products are safe for use in vehicle applications. This certification process encompasses several key areas, including material safety, performance under various environmental conditions, and long-term durability.

One of the primary reasons for obtaining CE certification for U-type EPDM gaskets is to bolster consumer confidence. Automotive manufacturers and consumers alike are increasingly aware of the importance of safety and compliance with regulatory standards. By ensuring that their gaskets are CE certified, manufacturers can assure end-users that their products are reliable and meet stringent safety requirements. This is particularly critical in the context of fuel systems, where leaks can lead to hazardous situations, including fire risks and environmental contamination.

ce certification u type epdm gasket for automobile fuel tank

In addition to enhancing consumer confidence, CE certification can provide a competitive edge in the automotive market. As cities and countries impose stricter regulations on automotive emissions and fuel efficiency, manufacturers must ensure that all components, including gaskets, comply with these guidelines. By presenting CE-certified products, companies can highlight their commitment to quality and safety, potentially influencing purchasing decisions of OEMs (Original Equipment Manufacturers) and aftermarket distributors.

Moreover, the process of achieving CE certification can also drive improvements in product design and manufacturing processes. To meet the certification requirements, manufacturers often engage in extensive research and development, leading to innovations in material formulations and production techniques. This continuous improvement not only enhances the performance of EPDM gaskets but can also result in cost savings and reduced waste, benefiting both manufacturers and the environment.

Finally, it is essential to consider the implications of globalization in the automotive industry. As vehicles are increasingly manufactured across different regions and exported worldwide, the compatibility of components with international standards becomes crucial. CE certification serves not only as a badge of quality within Europe but also as an indicator of reliability in global markets.

In conclusion, the CE certification of U-type EPDM gaskets for automobile fuel tanks is a vital aspect that ensures product safety, enhances consumer confidence, and promotes innovation in the automotive sector. As the industry continues to evolve, the emphasis on quality and compliance with regulatory standards will remain a focal point, given the critical role that such gaskets play in vehicle safety and efficiency. Manufacturers that prioritize CE certification will not only meet regulatory demands but also position themselves as leaders in the competitive landscape of the automotive industry.

Next: