Feb . 15, 2025 16:09 Back to list

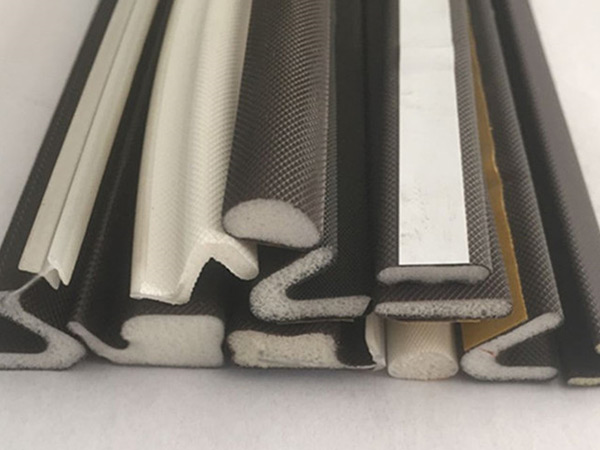

L-shaped staircase anti-skid strip

Choosing the right marine fender rubber sealing strip is crucial for ensuring the durability and efficiency of marine vessels. As a seasoned marine engineer with years of experience in naval architecture, I have gained in-depth knowledge about the intricacies involved in selecting quality fender solutions. A marine fender rubber sealing strip is not just a protective component; it is an assurance of safety and functionality for maritime operations.

Having worked in various marine projects around the globe, I have noticed a common oversight among operators – neglecting the maintenance schedule of fender systems. Regular inspection and maintenance are paramount for ensuring the sealing strips remain effective. Any signs of wear or damage should be promptly addressed to prevent any potential safety hazards or costly downtimes. Engaging with the community involved in marine operations can also provide practical insights. Forums, online reviews, and industry-specific groups are excellent resources to gather information about the performance of specific rubber sealing strips. Anecdotal experiences from other industry professionals can guide you toward making informed purchasing decisions. Certifications and compliance with industry standards are markers of a product's reliability and credibility. Ensure that the rubber sealing strips you select are certified by recognized marine organizations or testing bodies. Products adhering to standards, like ISO or ASTM, give confidence in their capacity to meet rigorous operational requirements. Ultimately, the right selection of a marine fender rubber sealing strip ties back to fundamental principles of quality, longevity, and reliability, underpinning every successful maritime venture. By prioritizing these aspects, operators can safeguard their vessels and infrastructure, enhancing operational efficiency and safety. Making informed choices with complete knowledge and expertise will always promise the best outcomes in maritime operations.

Having worked in various marine projects around the globe, I have noticed a common oversight among operators – neglecting the maintenance schedule of fender systems. Regular inspection and maintenance are paramount for ensuring the sealing strips remain effective. Any signs of wear or damage should be promptly addressed to prevent any potential safety hazards or costly downtimes. Engaging with the community involved in marine operations can also provide practical insights. Forums, online reviews, and industry-specific groups are excellent resources to gather information about the performance of specific rubber sealing strips. Anecdotal experiences from other industry professionals can guide you toward making informed purchasing decisions. Certifications and compliance with industry standards are markers of a product's reliability and credibility. Ensure that the rubber sealing strips you select are certified by recognized marine organizations or testing bodies. Products adhering to standards, like ISO or ASTM, give confidence in their capacity to meet rigorous operational requirements. Ultimately, the right selection of a marine fender rubber sealing strip ties back to fundamental principles of quality, longevity, and reliability, underpinning every successful maritime venture. By prioritizing these aspects, operators can safeguard their vessels and infrastructure, enhancing operational efficiency and safety. Making informed choices with complete knowledge and expertise will always promise the best outcomes in maritime operations.