Aug . 12, 2024 23:38 Back to list

Choosing the Best Manufacturer for Fuel Tank Gaskets in Automotive Applications

The Importance of Car Fuel Tank Gasket Manufacturers in Automotive Efficiency

In the automotive industry, every component plays a crucial role in ensuring the optimal performance of vehicles. Among these components, the fuel tank gasket may not be the most glamorous, but it is essential for the proper functioning of a vehicle's fuel system. Fuel tank gaskets, which serve as seals between the fuel tank and other parts of the fuel system, are critical in preventing leaks, maintaining pressure, and ensuring a vehicle runs efficiently. This article highlights the importance of car fuel tank gasket manufacturers and their role in the automotive sector.

The primary function of a fuel tank gasket is to provide a reliable seal that prevents fuel from leaking out of the tank. Given the flammable nature of gasoline and the importance of fuel efficiency, any leaks can be detrimental. A compromised gasket not only increases the risk of fire hazards but also results in fuel wastage, costing drivers more money at the pump while also harming the environment. Thus, manufacturers must produce high-quality gaskets that can withstand various conditions, including temperature fluctuations and exposure to chemicals.

When selecting a fuel tank gasket manufacturer, automotive companies consider several factors, such as material quality, manufacturing processes, and industry certifications. Many manufacturers specialize in producing gaskets from durable materials like rubber, neoprene, and silicone, which are designed to endure prolonged exposure to fuel. High-quality gaskets are designed to resist swelling, cracking, and other forms of degradation that could occur over time.

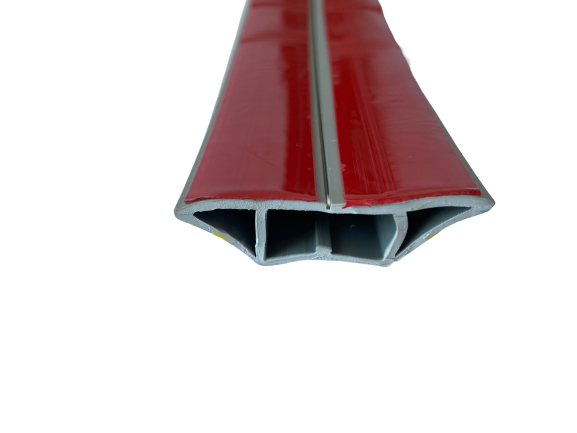

car fuel tank gasket manufacturer

Moreover, precision in manufacturing is crucial. Gaskets must fit perfectly to create a hermetic seal; even slight deviations can lead to failures. Hence, advanced manufacturing techniques, such as CNC machining and injection molding, are often employed to achieve the required tolerances. Manufacturers also invest in rigorous testing protocols to ensure that their products meet industry standards. Certifications from organizations like the Original Equipment Supplier Association (OESA) can be critical indicators of reliability and quality assurance.

Innovation plays a vital role in the gasket manufacturing industry as well. As automotive technology advances, especially with the rise of electric vehicles (EVs) and hybrid models, fuel systems are evolving. Manufacturers must adapt to these changes and develop gaskets that cater to the unique requirements of new fuel systems. For instance, with the increasing use of alternative fuels and biofuels, gaskets must be engineered to be compatible with these substances, ensuring no compromise in integrity or performance.

In addition to performance, there is a growing emphasis on sustainability within the industry. Many fuel tank gasket manufacturers are exploring eco-friendly materials and production methods. This trend reflects the wider movement in the automotive sector toward minimizing environmental impacts. By investing in sustainable practices, manufacturers not only contribute to an eco-friendlier industry but also appeal to a market that increasingly values corporate responsibility.

In conclusion, car fuel tank gasket manufacturers are vital players in the automotive supply chain. Their commitment to quality, precision, and innovation directly influences vehicle safety, performance, and environmental sustainability. As the automotive landscape continues to evolve with new technologies, the role of these manufacturers will only become more significant, ensuring that vehicles not only meet compliance standards but also cater to an eco-conscious consumer base. The contributions of these manufacturers enable the automotive industry to be more efficient, safer, and better aligned with global sustainability goals.