Aug . 06, 2024 05:01 Back to list

Comprehensive Overview and Technical Specifications of EPDM Rubber for Various Applications

Understanding EPDM Rubber Specifications and Applications

EPDM rubber, or Ethylene Propylene Diene Monomer, is a versatile synthetic rubber widely used in various industries due to its excellent properties. This article aims to shed light on the specifications and applications of EPDM rubber, highlighting its unique advantages and features.

Composition and Properties

EPDM rubber is a copolymer made from ethylene, propylene, and a diene component. The unique combination of these elements gives EPDM its distinct characteristics. One of the standout features of EPDM is its exceptional resistance to heat, ozone, and aging, which significantly extends its lifespan compared to other rubber types.

In terms of mechanical properties, EPDM offers good tensile strength, elongation at break, and tear resistance. Its flexibility at low temperatures is another crucial advantage, allowing it to maintain its properties in extreme weather conditions. Furthermore, EPDM has excellent electrical insulating properties, making it suitable for various electrical applications.

Specifications

A standard EPDM rubber specification sheet typically includes the following parameters

1. Hardness Measured in Shore A, the hardness of EPDM can range from 30 to 90. This property can be tailored to meet specific application requirements. 2. Tensile Strength EPDM displays tensile strength ranging from 7 to 25 MPa, making it robust enough for demanding applications. 3. Elongation at Break With a percentage often exceeding 300%, EPDM demonstrates remarkable flexibility and stretchability. 4. Temperature Resistance EPDM can withstand temperatures from -40°C to 120°C, making it suitable for both extremely cold and hot environments. 5. Ozone Resistance EPDM is well-known for its resistance to ozone, making it ideal for outdoor applications where environmental exposure is a concern. 6. Chemical Resistance While it is not suitable for use with petroleum-based products, EPDM is resistant to water, steam, and various mild chemicals, making it versatile in many conditions.

Applications

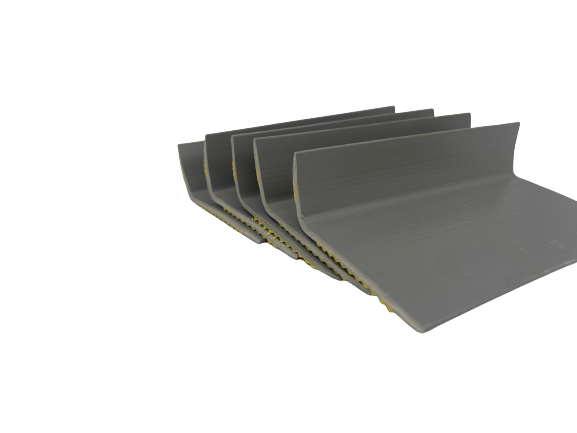

epdm rubber spec sheet

Given its desirable properties, EPDM rubber finds widespread use across various industries

1. Automotive EPDM is extensively used in the automotive sector for weather seals, hoses, and gaskets due to its durability and resistance to environmental elements.

2. Roofing and Construction EPDM roofing membranes are popular in commercial and residential buildings. They provide excellent waterproofing and UV resistance, ensuring long-term performance.

3. Electrical EPDM's electrical insulating properties make it valuable in making insulators, sheaths, and various components used in electrical appliances.

4. Manufacturing EPDM is commonly used in manufacturing seals, diaphragms, and automotive parts due to its mechanical strength and flexibility.

5. Consumer Goods Many everyday products, from toys to household items, utilize EPDM for its safety and durability.

Conclusion

In summary, EPDM rubber is a highly adaptable material with a range of specifications that make it suitable for various applications across multiple industries. Its unique properties—ranging from exceptional resistance to environmental factors to remarkable flexibility—ensure that it remains a preferred choice for manufacturers looking for durable and versatile materials. Understanding the specifications of EPDM rubber allows businesses and consumers alike to appreciate its value and potential for various applications, making it an essential material in today’s marketplace. As technology evolves, the applications of EPDM are expected to expand further, cementing its role in various fields.