Aug . 12, 2024 08:38 Back to list

Custom Rubber Seals for Plastic and Steel Doors and Windows to Enhance Energy Efficiency

The Importance of OEM Rubber Seals for Plastic Steel Doors and Windows

In modern construction and renovation projects, the significance of high-quality sealing solutions cannot be overstated. One of the most critical components that contribute to energy efficiency, durability, and overall performance of buildings are the OEM (Original Equipment Manufacturer) rubber seals used in plastic steel doors and windows. These seals play a vital role in ensuring that buildings are not only aesthetically appealing but also functional and energy-efficient.

Understanding OEM Rubber Seals

OEM rubber seals are specifically designed components manufactured to meet the exact specifications of original manufacturers of plastic steel doors and windows. Unlike generic seals, OEM products ensure a perfect fit and compatibility, which is crucial for optimal performance. The materials used in these seals are typically of high quality, providing excellent resistance to weather elements, UV rays, and other environmental factors. This quality is especially important for buildings exposed to harsh weather conditions.

Benefits of Using OEM Rubber Seals

1. Enhanced Energy Efficiency One of the primary functions of rubber seals is to provide insulation. They prevent drafts and the infiltration of external air, helping to maintain the interior temperature. This energy efficiency is essential not only for comfort but also for reducing energy costs, making OEM rubber seals a smart investment for homeowners and commercial property managers alike.

2. Noise Reduction In urban environments, noise pollution is a significant concern. OEM rubber seals offer excellent sound insulation properties, minimizing noise from external sources and ensuring a more peaceful indoor environment. This is especially vital for residential areas near busy roads or commercial zones.

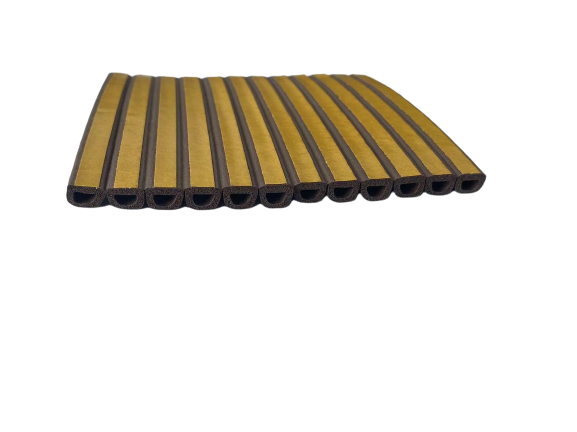

oem rubber seals for plastic steel doors and windows

3. Longevity and Durability Quality OEM seals made from premium rubber materials are designed to withstand the test of time. They are resistant to wear and tear, ensuring that they do not crack or degrade easily. This durability contributes to lower maintenance costs and fewer replacements, providing long-term value.

4. Corrosion Resistance Rubber seals are typically treated to resist corrosion, which is particularly important in locations with high humidity or exposure to chemicals. This feature prevents the possibility of seal degradation, ensuring that the integrity of the door and window installations remains intact over time.

5. Aesthetic Appeal Compliance with OEM standards means that rubber seals are designed to blend seamlessly with the overall aesthetic of the doors and windows. They are available in a variety of colors and finishes, allowing for customization that complements the existing decor and enhances the property's curb appeal.

Installation and Maintenance of Rubber Seals

To achieve optimal performance from OEM rubber seals, proper installation is crucial. It is advisable to engage professional services to ensure that the seals fit perfectly and provide the necessary insulation. Regular maintenance is also key; a simple inspection for damage or wear can prevent small issues from becoming significant problems. Cleaning the seals with mild soap and water can help maintain their elasticity and appearance, extending their lifespan.

Conclusion

In conclusion, OEM rubber seals for plastic steel doors and windows are essential components that significantly impact the functionality, efficiency, and comfort of any building. Their benefits extend beyond simple sealing; they contribute to energy savings, noise reduction, and aesthetic values. Investing in high-quality OEM rubber seals is a decision that pays off in long-term performance and satisfaction, making them indispensable in contemporary construction and renovation projects. Whether for residential or commercial applications, ensuring the best sealing solutions is crucial for a well-insulated and appealing space.