Jul . 26, 2024 17:34 Back to list

Customizable Marine Fender Seals Available to Meet Your Specific Needs and Requirements Today

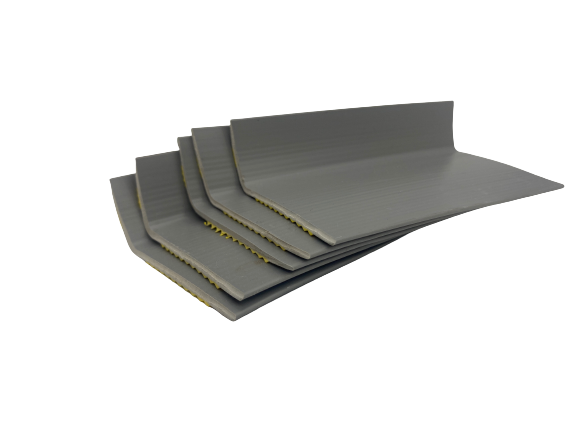

Customizable Marine Fender Seals A Solution for Your Docking Needs

Marine fender seals play a crucial role in protecting vessels during docking and mooring operations. They serve as an interface between the vessel and the docking structure, absorbing shock and reducing the risk of damage to both the ship and the dock. With the growing complexities of maritime operations, the demand for customizable marine fender seals is on the rise, allowing companies to tailor solutions that best fit their unique needs.

Importance of Customization

Every marine environment is different, and various factors influence the requirements for fender seals. The size and type of vessels, tidal movements, and the characteristics of the docking area all play a part in determining the appropriate fender seal design. Customizable marine fender seals offer manufacturers and shipping companies the flexibility to create products that align with their operational requirements.

Custom features can include variations in material composition, dimensions, and configurations. For instance, heavier-duty fender seals might be necessary for larger vessels or high-traffic areas, while lighter materials may suffice for smaller boats or less frequented docks. By customizing these seals, dock operators can ensure maximum protection for their vessels and docking structures while also prolonging the lifespan of the fendering system.

Materials and Design Considerations

marine fender seals can be customized quotes

When discussing customization, the choice of materials is paramount. Marine fender seals are typically constructed from robust materials such as rubber, polyurethane, or foam. Each material possesses distinct properties that affect durability, flexibility, and shock absorption. Customization can involve selecting a specific material that can withstand the harsh marine environment, including factors like UV exposure, water absorption, and temperature fluctuations.

Design considerations also play a significant role in the effectiveness of marine fender seals. Custom seals can be designed to fit specific docking structures, including pilings, bulkheads, or floating docks. The shape and profile of the fender seal contribute to its performance. For example, a wider surface area can distribute the impact more evenly, reducing localized stress points and minimizing damage.

Cost-Effectiveness and Efficiency

Investing in customized marine fender seals may initially seem more costly than opting for standard solutions; however, the long-term benefits far outweigh the initial expenditures. A well-designed fender system minimizes maintenance costs, reduces the potential for damages, and ensures safety in harbor operations. Additionally, tailored solutions can improve operational efficiency by decreasing downtime and enhancing the overall functionality of the dock.

Conclusion

In the competitive maritime industry, the emphasis on safety, efficiency, and cost-effectiveness cannot be overstated. Customizable marine fender seals represent a strategic solution for ship owners and dock operators aiming to protect their assets and optimize their operations. By understanding their specific needs and working with manufacturers who offer customizable options, maritime professionals can ensure that their docking facilities are equipped with the best protection possible. As the market for marine operations continues to evolve, embracing customization will become increasingly essential for meeting the diverse challenges faced in the marine environment.