Aug . 09, 2024 04:45 Back to list

Customizable ODM Marine Fender Seals for Enhanced Protection and Performance in Various Applications

Customizable ODM Marine Fender Seals A Perfect Solution for Your Maritime Needs

In the maritime industry, safety and protection are paramount, particularly in the context of mooring and berthing operations. ODM marine fender seals play a crucial role in safeguarding vessels from potential damage during these processes. What sets ODUs apart in the market is their unique ability to offer customizable marine fender seals tailored to meet specific requirements. This article delves into the importance of customizable marine fender seals, their applications, and the advantages they offer to shipbuilders and operators.

Marine fender seals are essential components designed to absorb the kinetic energy of vessels during berthing. They protect both the ship and docking facilities from collisions that can result in costly damage. Traditional fender solutions may not always address the unique challenges presented by various marine environments. This is where ODM (Original Design Manufacturer) comes into play, offering a level of customization that can accommodate diverse operational needs.

One of the main benefits of ODM marine fender seals is their ability to be tailored based on specific vessel specifications. Whether it's an oil tanker, a cargo ship, or a cruise liner, each vessel may require different fender configurations and sizes. ODM's custom solutions mean that clients can specify the dimensions, materials, and design features that best suit their operational context. For example, a port that handles heavy cargo ships may require larger, more durable fenders, while smaller harbors might only need smaller, less robust options.

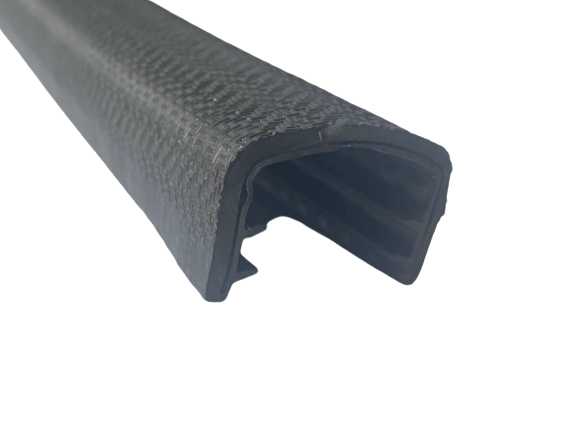

The materials used in the production of marine fender seals are another aspect that highlights the need for customization. Different marine environments and weather conditions necessitate different material choices. ODM provides a range of options, including rubber, polyethylene, and foam-filled fenders. These materials can be specially formulated to enhance performance in specific conditions, ensuring longevity and reliability.

odm marine fender seals can be customized

Furthermore, ODM marine fender seals can be designed with various attachment methods, such as chains, ropes, or molded-in fittings. This adaptability ensures that the fender seals can be easily integrated into existing mooring systems, enhancing operational efficiency. This is particularly important for retrofit projects, where existing infrastructures may require modification to accommodate new technology.

The process of customization is also streamlined by ODM's advanced manufacturing capabilities. With state-of-the-art technology and skilled craftsmen, ODM can quickly produce high-quality fender seals that meet precise specifications. This efficiency not only shortens delivery times but also reduces downtime for vessels, which is critical in the fast-paced maritime industry.

In addition, the customization aspect contributes significantly to sustainability efforts within the maritime sector. By creating fender seals that are specifically designed for particular applications, ODM minimizes waste and promotes the use of materials that have a lower environmental impact. Tailored manufacturing not only serves operational purposes but also aligns with the increasing emphasis on eco-friendly practices in shipping and maritime operations.

In conclusion, customizable ODM marine fender seals provide an essential solution in the maritime industry, merging functional performance with innovative design. Their adaptability to various vessel types and environmental conditions makes them a preferred choice among shipbuilders and marine operators. Whether for new constructions or retrofits, investing in custom marine fender seals from ODM guarantees the safety, efficiency, and sustainability of marine operations. As the maritime industry continues to evolve, the need for tailored solutions like those offered by ODM will be more critical than ever.