Sep . 25, 2024 20:49 Back to list

customizable silicone rubber sealing strip for oven door manufacturers

The Importance of Customizable Silicone Rubber Sealing Strips for Oven Doors

In the ever-evolving world of home appliances, a significant focus has been placed on enhancing energy efficiency, safety, and user-friendliness. Among the critical components that contribute to these enhancements are sealing strips, specifically silicone rubber sealing strips designed for oven doors. As manufacturers continue to innovate, the demand for customizable options has risen drastically, allowing producers to meet diverse consumer needs while maintaining high-quality standards.

Understanding Silicone Rubber Sealing Strips

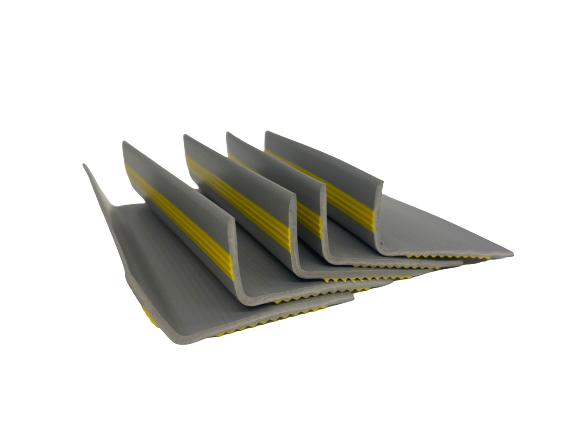

Silicone rubber is a synthetic material revered for its excellent heat resistance, flexibility, and durability. These properties make it an ideal choice for oven door sealing strips, which must withstand high temperatures while providing an airtight seal. A good sealing strip ensures that the heat stays inside the oven, improves energy efficiency, and prevents heat loss, thus saving on electricity costs and enhancing cooking performance.

The sealing strips not only serve functional purposes but also contribute to safety. A well-fitted sealing strip minimizes the risk of burns or accidental exposure to high temperatures, making it an essential part of any oven design. Furthermore, they also help in improving the overall aesthetic of the appliance, creating a seamless look that appeals to consumers.

Customization The Key to Meeting Diverse Needs

The main advantage of customizable silicone rubber sealing strips lies in their adaptability. Manufacturers can modify these strips in various ways to suit specific oven models, user preferences, or design requirements. Custom options may include varying thicknesses, lengths, colors, and even shapes. This flexibility allows manufacturers to cater to a wide range of oven designs, from traditional models to modern, high-efficiency appliances.

For instance, a high-end oven might require a more robust sealing strip with enhanced insulation properties, while a budget model could utilize a standard design that still meets essential performance criteria

. The ability to customize not only helps in addressing specific functional needs but also enhances brand identity, as manufacturers can use unique designs or colors to differentiate their products in the marketplace.customizable silicone rubber sealing strip for oven door manufacturers

Manufacturing Considerations

When it comes to producing customizable silicone rubber sealing strips, manufacturers must prioritize quality and consistency. The production process typically involves mixing silicone compounds and curing them to form sturdy strips. It is vital that these materials are sourced from reliable suppliers to ensure that the strips can endure high temperatures and maintain their shape over time.

Furthermore, advancements in manufacturing technologies, such as 3D printing, have made it easier to produce tailored solutions quickly, allowing manufacturers to respond to market demands more effectively. This agility in production is pivotal in today’s competitive marketplace, where consumer expectations are continually evolving.

Environmental Impact

In recent years, sustainability has become a focal point for consumers when purchasing appliances and their components. Many manufacturers are now exploring eco-friendly options for their silicone rubber sealing strips, including the use of recyclable materials or processes that minimize waste. Customizable silicone sealing strips can also be designed for longevity, reducing the need for frequent replacements and thereby lessening the environmental footprint.

Conclusion

In conclusion, customizable silicone rubber sealing strips for oven doors represent a crucial aspect of modern appliance manufacturing. By prioritizing quality, safety, and environmental consciousness, manufacturers can create sealing solutions that not only meet consumer needs but also elevate their brand's standing in a competitive landscape. As the industry continues to innovate, the future of customizable sealing strips looks promising, with endless possibilities for enhancing efficiency, safety, and user experience in everyday cooking appliances.