Nov . 11, 2024 22:35 Back to list

customizable waterproof and soundproof rubber sealing strip for car windows manufacturers

Customizable Waterproof and Soundproof Rubber Sealing Strips for Car Windows An Overview

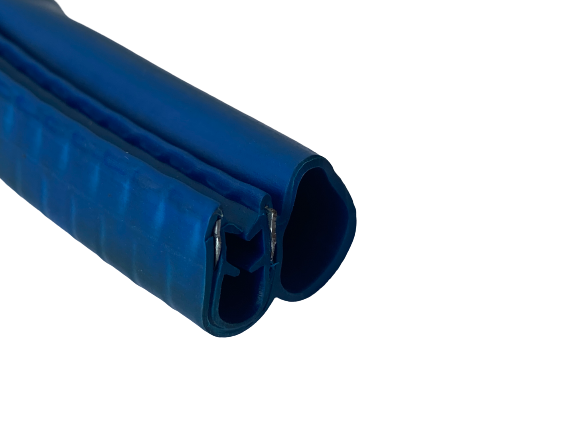

In the automotive industry, ensuring the highest quality and performance of vehicles is paramount. One often overlooked yet crucial component that significantly contributes to vehicle quality is the sealing strip used around car windows. Customizable waterproof and soundproof rubber sealing strips have emerged as essential elements for enhancing both the functionality and comfort of vehicles.

Importance of Sealing Strips

Sealing strips serve multiple purposes. Primarily, they create a waterproof barrier that prevents water ingress, which can damage electronic components and interiors over time. Additionally, these strips act as insulators, blocking out unwanted noise from the external environment. This dual functionality not only enhances the longevity of the vehicle but also significantly improves the driving experience by providing a quieter cabin atmosphere.

Customization Meeting Diverse Needs

One of the standout features of modern rubber sealing strips is their customizable nature. Manufacturers understand that different vehicles and models have varying requirements. By offering customizable options, they can cater to the specific needs of car manufacturers and end-users alike.

Customizable sealing strips can be tailored in terms of length, width, shape, and hardness. This flexibility ensures that the sealing strips perfectly fit the unique contours of different car windows and body designs. For instance, premium luxury vehicles may require thicker, softer strips for enhanced soundproofing, while utility vehicles may benefit from more robust, weather-resistant materials.

Materials Used

The materials used in the production of waterproof and soundproof rubber sealing strips are critical to their performance. High-quality EPDM (Ethylene Propylene Diene Monomer) rubber is commonly employed due to its excellent weather resistance, temperature stability, and durability. This material can withstand extreme weather conditions, making it ideal for use in various climates.

customizable waterproof and soundproof rubber sealing strip for car windows manufacturers

Additionally, manufacturers might use advanced composite materials that include acoustic damping properties. These materials not only provide effective waterproofing but also significantly minimize sound transmission, contributing to a more serene cabin environment.

Manufacturing Process

The production of these sealing strips involves several steps to ensure they meet the rigorous demands of the automotive sector. The process begins with the selection of raw materials, followed by precise molding to create the desired shape. Advanced manufacturing techniques, such as extrusion and injection molding, are employed to achieve high levels of accuracy and consistency.

Furthermore, quality control processes are integral to the manufacturing of sealing strips. Each batch undergoes rigorous testing to ensure that they meet established standards for water resistance, sound insulation, and overall durability. This attention to detail guarantees that the sealing strips will perform effectively in their intended applications.

Market Trends and Innovations

As consumers increasingly demand quieter and more comfortable vehicles, the market for customizable waterproof and soundproof rubber sealing strips continues to grow. Innovations in material science are driving advancements in this field, with manufacturers exploring new polymer blends and coatings that enhance performance attributes.

Moreover, eco-friendly materials are gaining traction, responding to the automotive industry's push towards sustainability. Manufacturers are now exploring bio-based rubbers and recyclable compounds to reduce the environmental footprint of automotive products, including sealing strips.

Conclusion

In summary, customizable waterproof and soundproof rubber sealing strips are vital components that enhance vehicle performance, comfort, and longevity. As the automotive industry evolves, the demand for these components will continue to rise. By investing in high-quality, tailored sealing solutions, manufacturers can ensure that their vehicles not only meet but exceed customer expectations for performance and comfort. With ongoing innovations and a focus on sustainability, the future of rubber sealing strips looks promising, paving the way for even quieter and more resilient vehicles.