Aug . 07, 2024 18:50 Back to list

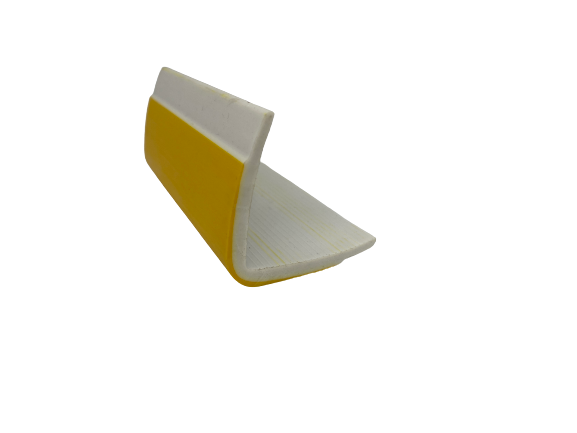

Customized Marine Fender Seals Available from Reliable Suppliers for Optimal Performance and Durability

Customizable Marine Fender Seals A Vital Component for Maritime Safety

Marine fender seals play a critical role in ensuring the safety and operational efficiency of maritime vessels while they dock or moor. With the increasing demands of maritime operations, the need for customizable solutions has become essential. Suppliers that specialize in marine fender seals provide various options tailored to meet specific needs of clients, ensuring optimal performance, durability, and safety.

Understanding Marine Fender Seals

Marine fender seals are protective components made from robust materials designed to absorb the impact between vessels and docking structures. These seals help to prevent damage to both the ship and the wharf, facilitating secure and effective docking operations. They can be made from various materials, including rubber, polyurethane, and composite materials, depending on the application and environmental conditions.

The Importance of Customization

Every marine operation has unique requirements based on factors such as the type of vessel, loading conditions, and the specific environment where the fender will be used. Customized marine fender seals allow operators to specify dimensions, material types, and performance characteristics. This level of customization is crucial for several reasons

1. Optimized Performance Tailored fender seals ensure that the fendering system can handle the specific loads and impacts expected in particular marine environments. This results in better shock absorption and reduces the risk of damage during docking procedures.

2. Enhanced Durability Custom manufacturers often utilize advanced materials that are resistant to weathering, UV exposure, and marine growth. Customization allows for the selection of materials that can withstand the environmental challenges specific to a location, prolonging the lifespan of the fender seals.

3. Cost Efficiency By tailoring fender seals to the needs of specific operations, companies can avoid overspending on unnecessary materials or features. Custom products can lead to cost savings in both the short and long term by reducing maintenance and replacement needs.

4. Improved Safety The marine industry carries inherent risks, and improper fendering can lead to accidents that result in injury or damage. Customized fender seals contribute to safer operations by ensuring that vessels are protected effectively against sudden impacts.

marine fender seals can be customized supplier

Working with Custom Suppliers

When seeking a supplier for customizable marine fender seals, it is vital to consider their expertise and capability in providing tailored solutions. A reputable supplier will not only offer a range of materials and designs but will also have the capacity to collaborate with clients to understand their specific needs.

Key factors to consider when selecting a supplier include

- Experience and Reputation Look for suppliers with a proven track record in the marine industry who can provide references or case studies demonstrating successful customization projects.

- Material Options A good supplier should offer a wide variety of materials suitable for different marine conditions and align with your project's requirements.

- Technical Support Suppliers who provide comprehensive support, including design assistance and installation guidance, can be invaluable in ensuring optimal performance of the fender seals.

- Quality Assurance Ensure that the supplier adheres to strict quality control measures. Certifications and standards compliance can indicate reliability and durability.

Conclusion

Customizable marine fender seals are essential for maintaining safe and efficient marine operations. By choosing the right supplier who can provide tailored solutions, maritime operators can ensure that their vessels are adequately protected, ultimately leading to improved safety, cost efficiency, and operational effectiveness. Investing in high-quality, customizable fender seals is not just a matter of compliance; it is a critical part of maintaining safety and efficiency in today's rapidly evolving maritime industry.