Jul . 26, 2024 17:35 Back to list

Customized Marine Fender Seals Designed for Optimal Performance by Trusted Manufacturers Worldwide

Customizable Marine Fender Seals A Comprehensive Overview

In the maritime industry, ensuring the safety and protection of vessels during docking and berthing processes is paramount. One of the critical solutions to facilitate this safety is the use of marine fender systems. A vital component of these systems is the fender seal, which often requires customization to meet specific operational needs. As a customizable marine fender seal manufacturer, we recognize the significance of tailored solutions in ensuring optimal performance and durability in challenging marine environments.

Marine fenders serve as shock absorbers, effectively reducing the impact of vessels against docks, piers, and other ships. The fender seals play an essential role in maintaining the integrity and functionality of these fender systems. Their primary function is to provide a robust, flexible, and protective barrier that minimizes wear and tear while also ensuring that the fender retains its shape and performance under varying load conditions.

The Need for Customization

The requirements for marine fender seals can significantly vary based on a multitude of factors, including the type of vessel, the docking environment, and specific operational demands. Different ports may encounter unique challenges like tidal variations, heavy traffic, or extreme weather conditions. In such cases, standardized fender seals may not suffice. This is where customization comes into play, allowing manufacturers to design seals that cater specifically to the individual needs of each client.

Customizable marine fender seals can be produced in various shapes, sizes, and materials. The selection of materials is crucial, as it impacts the seal’s resistance to abrasion, ozone, UV exposure, and temperature fluctuations. Common materials used include natural rubber, synthetic rubber, and thermoplastic elastomers, each presenting distinct advantages based on the end-user’s requirements.

Manufacturing Process

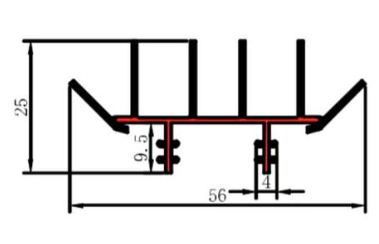

marine fender seals can be customized manufacturer

The production of customized marine fender seals involves a rigorous manufacturing process. It begins with extensive consultation with clients to assess their needs, followed by design and engineering phases where specifications are drafted. Advanced manufacturing techniques, including extrusion and molding processes, enable the creation of seals with precise dimensions and performance characteristics.

Upon completion, each batch of marine fender seals undergoes rigorous quality control assessments. Testing procedures ensure that the seals maintain their integrity and functionality under realistic operational conditions. In addition, many manufacturers are increasingly focusing on sustainability by sourcing eco-friendly materials and implementing greener production methods to reduce the environmental impact.

Benefits of Customization

The benefits of utilizing customized marine fender seals are manifold. Primarily, they enhance the overall safety of operations by providing superior protection against collisions. This, in turn, can reduce repair costs for both vessels and docking facilities. Additionally, customized solutions can lead to increased longevity of fender systems, reducing the frequency of replacements and thereby resulting in significant cost savings over time.

Moreover, having a tailored fender seal can improve efficiency in docking operations. With better performance in absorbing impact, vessels can dock more quickly and safely, minimizing congestion in busy ports. This efficiency is especially important in today’s increasingly high-pressure maritime environments.

Conclusion

In conclusion, the significance of customizable marine fender seals cannot be overstated. As marine operations grow more complex and demanding, manufacturers must adapt to provide tailored solutions that enhance safety, efficiency, and durability. By prioritizing customization in marine fender seal manufacturing, we can better meet the diverse needs of the maritime industry, ultimately contributing to smoother, safer, and more efficient port activities around the globe.