Nov . 18, 2024 17:47 Back to list

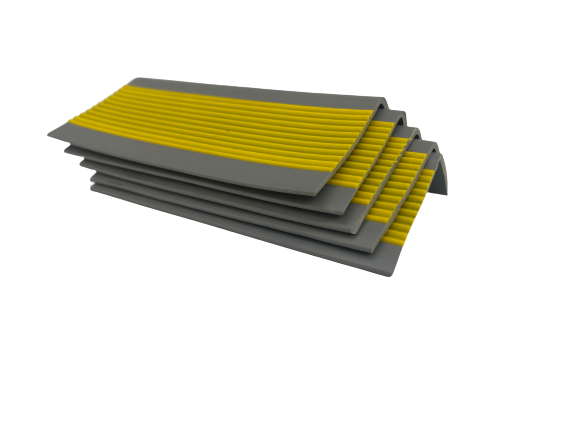

custom rubber sealing strip for aluminum alloy doors and windows

Custom Rubber Sealing Strips for Aluminum Alloy Doors and Windows

In today's modern architecture, aluminum alloy doors and windows are favored for their durability, sleek aesthetics, and excellent thermal performance. However, to fully capitalize on these benefits, a reliable sealing solution is paramount. Custom rubber sealing strips have emerged as an essential component in ensuring the effectiveness, longevity, and energy efficiency of these fixtures.

The Importance of Sealing Strips

Sealing strips play a crucial role in preventing air and water infiltration, which can compromise the integrity of doors and windows. When gaps exist due to poor fit or wear, they can lead to significant energy loss, increased heating and cooling costs, and diminished comfort within indoor spaces. Furthermore, moisture ingress can cause damage to the structural elements of a building and potentially lead to mold growth, posing health risks.

Rubber sealing strips are particularly suitable for aluminum alloy doors and windows due to their superior flexibility, resilience, and water-resistant properties. These materials not only enhance the overall performance of the door and window systems but also contribute to the aesthetic appeal by providing a neat and finished look.

Customization for Specific Needs

One of the main advantages of rubber sealing strips is their customizability. Each building may have unique requirements based on architectural design, climate conditions, and user preferences. By utilizing custom rubber sealing strips, manufacturers can offer tailored solutions that meet specific needs, enhancing the overall functionality and performance of entrance systems.

Custom sealing strips can be designed in various shapes, sizes, and hardness levels, making them suitable for a wide range of applications. This allows for efficient sealing around the edges of aluminum doors and windows, ensuring a snug fit that prevents air leakage and moisture infiltration. Moreover, custom solutions can incorporate specific features, such as UV resistance for sun-exposed installations or fire-retardant properties for enhanced safety in commercial buildings.

Manufacturing Process

The manufacturing of custom rubber sealing strips involves several key stages. Initially, the exact specifications of the needed sealing strip are determined, including dimensions, material type, and performance characteristics. Companies typically utilize computer-aided design (CAD) software to create precise prototypes. Once the design is finalized, the strips are produced using various processes, such as extrusion or molding.

custom rubber sealing strip for aluminum alloy doors and windows

Modern technologies allow manufacturers to blend different rubber compounds, tailoring them to withstand specific environmental conditions—be it heat, cold, or humidity. This adaptability ensures that the sealing strips remain functional and effective over time, minimizing the need for replacement or maintenance.

Benefits of Using Custom Rubber Sealing Strips

1. Energy Efficiency By effectively sealing gaps, custom rubber strips reduce air leaks, thereby improving energy performance. Buildings remain more comfortable with less reliance on heating and cooling systems, translating to lower energy bills.

2. Durability High-quality rubber sealing strips are designed to withstand wear and tear, ensuring a long-lasting solution that requires minimal upkeep. Many rubber materials exhibit exceptional resistance to weathering, UV rays, and certain chemicals, further enhancing their longevity.

3. Enhanced Comfort Properly sealed doors and windows reduce drafts and maintain a consistent indoor temperature, leading to improved comfort for occupants. This becomes especially important in environments with extreme temperatures.

4. Noise Reduction Rubber sealing strips can also provide sound insulation, helping to create a quieter indoor environment by minimizing noise transmission from outside.

5. Aesthetic Appeal Custom solutions can be crafted to match the design of the aluminum doors and windows while remaining discreet, ensuring a cohesive and professional appearance.

Conclusion

Custom rubber sealing strips are a critical component in maximizing the performance of aluminum alloy doors and windows. By ensuring airtight and watertight seals, they contribute significantly to the energy efficiency, comfort, and durability of buildings. With advances in manufacturing technology and the ability to tailor solutions to specific needs, these sealing strips stand out as a smart investment for both residential and commercial applications. Whether it’s enhancing the energy performance of homes or ensuring the safety and comfort of office spaces, custom rubber sealing strips prove that the details matter in modern construction.