Oct . 10, 2024 18:08 Back to list

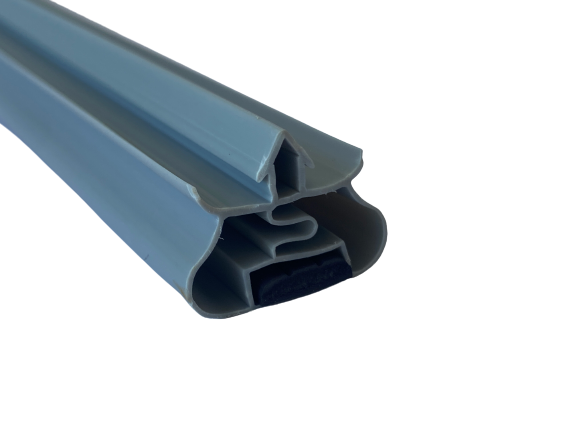

Custom Rubber Strips for Various Applications and Industries

Custom rubber strips are versatile products used across various industries for a multitude of applications. These strips can be tailored to meet specific requirements, including size, shape, thickness, and material composition. As businesses increasingly seek solutions that cater to their unique needs, the demand for custom rubber strips has grown significantly.

One of the primary advantages of custom rubber strips is their ability to provide a reliable solution for sealing, cushioning, and protecting surfaces in different environments. Industries such as automotive, construction, electronics, and consumer goods frequently utilize these strips for a variety of purposes. For example, in the automotive sector, rubber strips are commonly used as seals around doors and windows to prevent water and air leaks. In construction, they can serve as expansion joints, helping to accommodate movement and reduce stress on structures.

The manufacturing process for custom rubber strips typically involves advanced techniques such as extrusion and molding. Extrusion is a common method where rubber is pushed through a die to create long, continuous shapes that can be cut to desired lengths. Meanwhile, molding involves shaping rubber into specific forms using heat and pressure, allowing for intricate designs that can provide enhanced functionality. Advances in technology have allowed manufacturers to create rubber strips with varying degrees of elasticity, durability, and resistance to factors such as temperature, chemicals, and UV exposure.

Another significant benefit of custom rubber strips is their adaptability to diverse environmental conditions. Companies can select materials that are best suited for their specific applications, whether they require rubber that is resistant to harsh chemicals or one that can withstand extreme temperatures. For instance, silicone rubber strips are often chosen for high-temperature applications, while EPDM (ethylene propylene diene monomer) rubber strips are favored for their excellent weather resistance.

custom rubber strips

In addition to functional benefits, custom rubber strips also contribute to the overall aesthetics of products. With an array of colors and finishes available, companies can choose rubber strips that not only perform well but also enhance the visual appeal of their products. This is particularly important in consumer goods where branding and presentation play a crucial role in attracting customers.

As sustainability becomes increasingly important, manufacturers are also exploring eco-friendly options for producing rubber strips. Incorporating recycled materials into the production process and using sustainable practices can help meet the growing demand for environmentally responsible solutions. This shift not only appeals to environmentally-conscious consumers but can also give businesses a competitive edge.

When selecting a supplier for custom rubber strips, it’s essential to consider their experience, quality assurance processes, and ability to collaborate on design specifications. A reliable supplier will work closely with clients to understand their needs and provide recommendations based on industry best practices.

In conclusion, custom rubber strips are essential components in a wide range of applications across numerous industries. Their ability to be tailored to specific needs, alongside their functional and aesthetic benefits, makes them a popular choice for manufacturers aiming to enhance product performance and design. As technology and eco-conscious practices continue to evolve, the future of custom rubber strips looks promising, paving the way for innovative solutions in various markets.