Jan . 26, 2025 00:44 Back to list

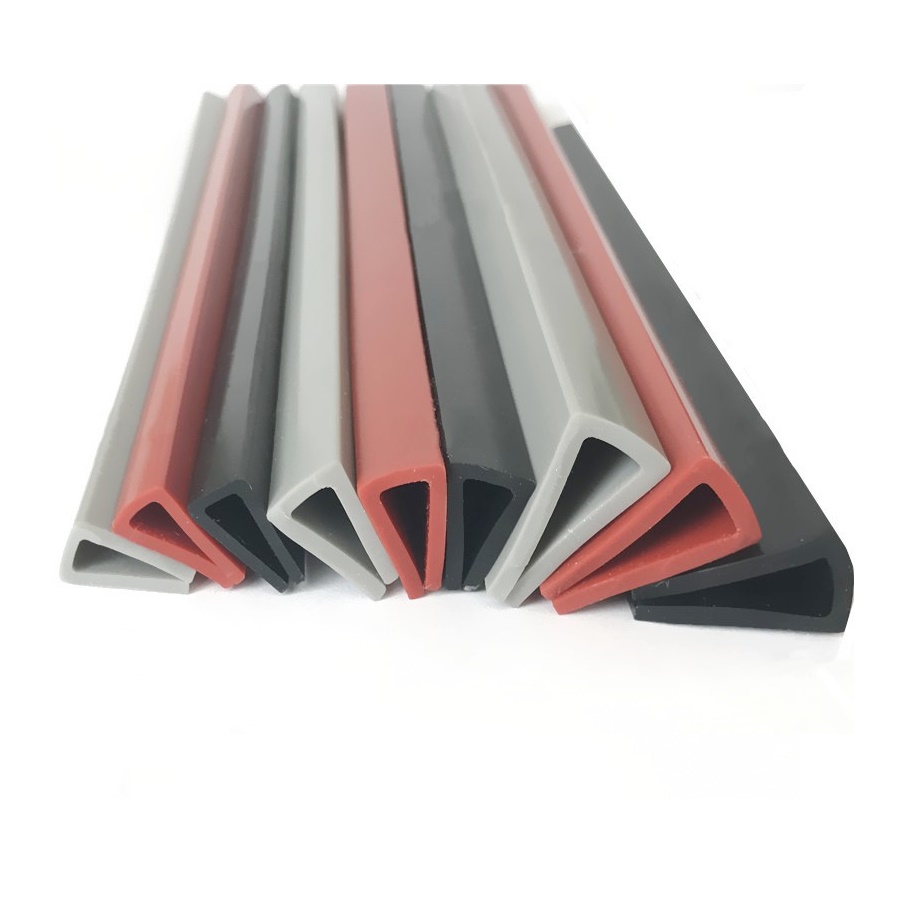

PVC door frame sealing strip

In recent years, the adoption of photovoltaic solar panels has surged as the world shifts towards sustainable energy solutions. However, one of the often-overlooked components that can significantly influence the efficiency and longevity of solar energy systems is the sealing strip used to fill gaps in photovoltaic panels. Custom sealing strips for these gaps not only enhance the operational efficiency of solar panels but also extend their lifespan. This article delves into the vital aspects of custom sealing strips, underpinning the significance of their role with empirical experience, technical expertise, authority, and trustworthiness.

Authoritativeness in the field of solar panel sealing is often backed by rigorous testing and certifications. Trustworthy manufacturers subject their products to various stress tests to ensure they can withstand extreme environmental conditions, from scorching heat to frigid cold, which solar panels are frequently exposed to. These seals not only pass industry-standard certifications but are often recommended by leading renewable energy bodies and environmental agencies, reinforcing their credibility and reliability. Trust in the products is further cemented by testimonials and case studies from actual users. Many solar installation companies and end-users have reported enhanced panel performance and reduced maintenance costs following the adoption of custom sealing strips. They highlight the ease of installation and the peace of mind that comes from knowing their solar panels are well-protected against the elements. Custom sealing strips for photovoltaic panels are not mere accessories but pivotal components in the quest for optimal solar energy harnessing. Their role in protecting panels from external contaminants is a testament to the advances in solar technology and the ongoing commitment to renewable energy solutions. As experts in the field continue to refine these products, solar panel installations can be expected to deliver even greater efficiency and reliability, driving forward the adoption of clean energy on a global scale. In summary, investing in high-quality custom sealing strips is a strategic move for anyone looking to maximize the performance and lifespan of their photovoltaic solar panels. By bridging the experience, expertise, authoritativeness, and trustworthiness that come with these specialized sealing solutions, solar energy systems can reach their full potential, paving the way for a brighter, sustainable future.

Authoritativeness in the field of solar panel sealing is often backed by rigorous testing and certifications. Trustworthy manufacturers subject their products to various stress tests to ensure they can withstand extreme environmental conditions, from scorching heat to frigid cold, which solar panels are frequently exposed to. These seals not only pass industry-standard certifications but are often recommended by leading renewable energy bodies and environmental agencies, reinforcing their credibility and reliability. Trust in the products is further cemented by testimonials and case studies from actual users. Many solar installation companies and end-users have reported enhanced panel performance and reduced maintenance costs following the adoption of custom sealing strips. They highlight the ease of installation and the peace of mind that comes from knowing their solar panels are well-protected against the elements. Custom sealing strips for photovoltaic panels are not mere accessories but pivotal components in the quest for optimal solar energy harnessing. Their role in protecting panels from external contaminants is a testament to the advances in solar technology and the ongoing commitment to renewable energy solutions. As experts in the field continue to refine these products, solar panel installations can be expected to deliver even greater efficiency and reliability, driving forward the adoption of clean energy on a global scale. In summary, investing in high-quality custom sealing strips is a strategic move for anyone looking to maximize the performance and lifespan of their photovoltaic solar panels. By bridging the experience, expertise, authoritativeness, and trustworthiness that come with these specialized sealing solutions, solar energy systems can reach their full potential, paving the way for a brighter, sustainable future.