Nov . 10, 2024 02:20 Back to list

D-Type Ship Anti-Collision Rubber Sealing Strip for Enhanced Maritime Safety and Protection

The Importance of D-Type Ship Anti-Collision Rubber Sealing Strips

In the maritime industry, safety is of paramount importance, especially concerning the design and functionality of ships. Among the various components contributing to a ship's integrity, D-type anti-collision rubber sealing strips have emerged as a vital element in ensuring the safety and longevity of vessels. These specialized rubber strips serve multiple purposes, from protecting structural components to enhancing the overall resilience of maritime crafts.

Understanding the D-Type Sealing Strip

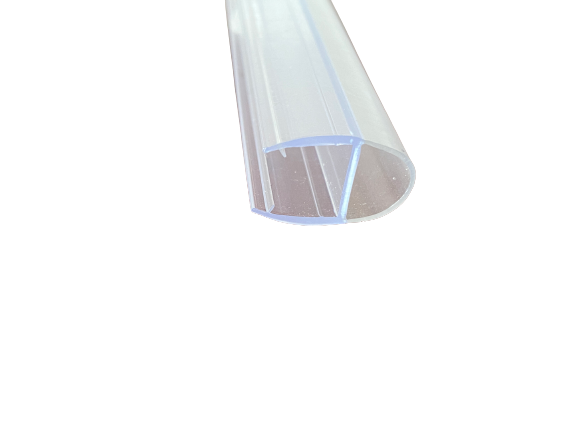

The D-type anti-collision rubber sealing strip is characterized by its unique cross-sectional shape, which resembles the letter D. This design is not merely for aesthetics; it provides exceptional cushioning and compression resistance. The primary function of these sealing strips is to absorb impacts during docking and mooring, which are common instances where ships might come into contact with jetties, other vessels, or hard surfaces. By minimizing the force transferred to the ship's hull, these strips significantly reduce the risk of dents, structural damage, and subsequent repair costs.

Features and Benefits

1. Material Durability Made from high-quality rubber compounds, D-type sealing strips exhibit excellent resistance to weathering, UV rays, and chemical exposure. This durability ensures that the strips maintain their protective qualities over extended periods, even in harsh marine environments.

2. Easy Installation Designed for convenience, these sealing strips can be easily attached to a variety of surfaces on a ship. The flexibility of the rubber allows it to conform to different shapes and angles, ensuring a snug fit that enhances performance.

3. Cost-Effectiveness By preventing damage to the ship’s hull and related components, D-type sealing strips can save ship owners significant amounts in repair and maintenance costs. Investing in these protective strips is a proactive approach to minimizing long-term operational expenses.

d-type ship anti-collision rubber sealing strip

4. Noise and Vibration Dampening In addition to impact protection, these sealing strips help to reduce noise and vibration during operations. This feature results in a more comfortable experience for crew members and passengers, contributing to overall onboard satisfaction.

Application in Various Marine Settings

D-type anti-collision rubber sealing strips are versatile and can be utilized in various marine applications. Ships of all sizes, including ferries, cargo vessels, and recreational boats, can benefit from their protective qualities. Moreover, they are commonly used in port facilities and marinas to safeguard not only the vessels but also the infrastructure from damage during docking procedures.

Maintenance and Lifespan

While D-type sealing strips are designed for durability, regular maintenance is essential to maximize their lifespan. Periodic inspections for wear and tear, as well as cleaning to remove salt and debris, will help maintain their effectiveness. Replacing worn or damaged strips promptly ensures that the ship's protective measures remain intact, further enhancing its safety profile.

Conclusion

In conclusion, D-type ship anti-collision rubber sealing strips play an essential role in the maritime industry by providing a robust barrier against the challenges posed by docking and mooring. Their blend of durability, ease of installation, and cost-effectiveness makes them a critical component of ship design and maintenance. As the industry continues to prioritize safety and efficiency, the importance of such protective measures will only grow, reinforcing the need for innovative solutions that enhance vessel integrity and operational longevity. Investing in quality D-type sealing strips is not just a choice; it is an imperative for responsible shipowners committed to ensuring the safety and resilience of their vessels.