Nov . 14, 2024 22:46 Back to list

d-type ship anti-collision sealing strip supplier

D-Type Ship Anti-Collision Sealing Strip Supplier Ensuring Maritime Safety

In the complex world of maritime operations, safety is paramount. One crucial aspect of ensuring the safety of vessels is the implementation of effective anti-collision measures. Among the various components used for this purpose, D-type ship anti-collision sealing strips play a vital role. This article examines the importance of these sealing strips, their benefits, and the significance of selecting a reliable supplier.

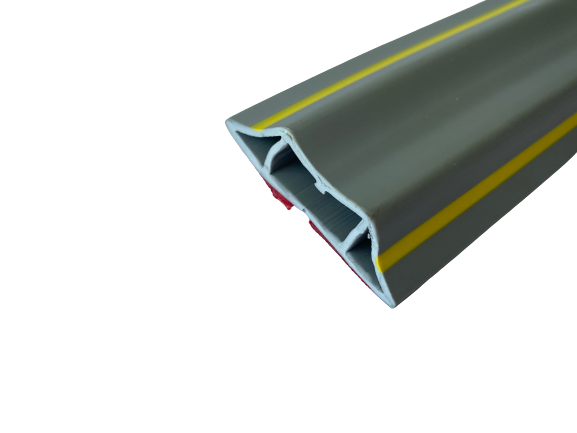

D-type anti-collision sealing strips are designed to absorb impact and provide cushioning during collisions, reducing the potential for damage to both ships and ports. They are specifically engineered to withstand harsh marine conditions, including extreme weather, saltwater corrosion, and heavy impacts. These strips are typically made from high-quality synthetic rubber or resilient materials that ensure durability and longevity in demanding environments.

The primary function of these sealing strips is to provide an effective barrier against collisions. When ships make contact with docks or other vessels, the D-type sealing strips help to minimize the force of impact, protecting the hull and structural integrity of the ships involved. This is particularly important in busy ports where vessels frequently maneuver in close proximity to one another. By absorbing shock and preventing potential breaches, these strips contribute significantly to the safety of maritime operations.

Moreover, D-type anti-collision sealing strips are designed to enhance the operational efficiency of vessels. They facilitate smooth docking and undocking processes, allowing ships to navigate in tighter spaces without the risk of sustaining damage. This efficiency is crucial for shipping companies that prioritize timely deliveries and operational excellence.

d-type ship anti-collision sealing strip supplier

When selecting the right supplier for D-type anti-collision sealing strips, several factors should be taken into consideration. Quality is paramount. A reputable supplier will offer sealing strips that meet international safety standards and have a proven track record in the marine industry. Quality assurance measures, such as material certifications and rigorous testing protocols, should be part of the supplier’s offerings to ensure that the products are reliable and effective.

In addition to quality, the supplier's experience and expertise in maritime applications are essential. A well-established supplier understands the unique demands of the maritime industry and can provide tailored solutions to meet specific requirements. This includes offering customizable options for sealing strips that can adapt to different ship designs and types, ensuring a perfect fit and optimal performance.

Furthermore, customer service and support are crucial components of a reliable supplier relationship. A supplier that offers comprehensive technical support, prompt communication, and efficient delivery services contributes to a seamless purchasing experience. This is especially important in maritime operations, where timely availability of parts and materials can significantly impact operational schedules.

Another consideration is the supplier's commitment to sustainability. As the maritime industry increasingly focuses on environmentally friendly practices, choosing a supplier that utilizes eco-friendly materials and processes can align with your organization's goals of reducing its carbon footprint.

In conclusion, D-type ship anti-collision sealing strips are indispensable components that enhance maritime safety and operational efficiency. When sourcing these critical elements, partnering with a reputable supplier who prioritizes quality, expertise, and customer support is vital. By doing so, shipping companies can ensure they are well-equipped to face the challenges of maritime navigation while safeguarding their vessels and maintaining high standards of safety in the ever-evolving maritime landscape.