Oct . 17, 2024 15:38 Back to list

Door and Window Sealing Strip Manufacturing Solutions for Enhanced Home Insulation

Door and Window Sealing Strip Factory Ensuring Comfort and Energy Efficiency

In today's world, energy efficiency has become a significant concern for homeowners and businesses alike. One often-overlooked aspect that plays a crucial role in conserving energy is the sealing of doors and windows. This is where a door and window sealing strip factory comes into play, producing essential materials that enhance comfort, reduce energy costs, and improve indoor air quality.

The Importance of Sealing Strips

Windows and doors are typically the primary entry points for air leaks in a building. When these openings are not properly sealed, heat can escape during the winter, and cool air can vanish in the summer. This can lead to increased energy bills and an uncomfortable indoor environment. Sealing strips are designed to fill gaps and cracks around doors and windows, providing an airtight seal that minimizes air leakage.

The benefits of using sealing strips extend beyond energy savings. They also help prevent dust, pollen, and noise from entering your home or office space. By creating a more controlled indoor environment, sealing strips contribute to a healthier living and working space.

The Manufacturing Process

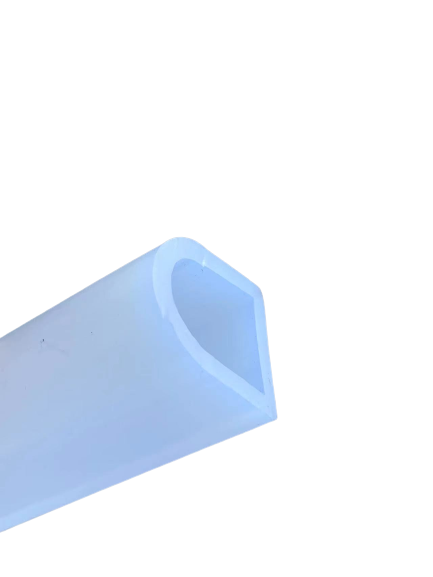

A door and window sealing strip factory employs various materials and manufacturing techniques to produce high-quality products. The most common materials used are rubber, foam, and weather-resistant polymers. Each of these materials offers different levels of insulation, durability, and flexibility, catering to a variety of applications.

1. Material Selection Choosing the right material is crucial. Rubber sealing strips are known for their resilience and are effective in extreme weather conditions. Foam strips provide excellent insulation and are often used in residential settings. Polymers are favored for their flexibility and resistance to aging.

2. Molding and Extrusion The manufacturing process typically involves molding and extrusion techniques. In molding, raw materials are heated and shaped into specific profiles, while extrusion involves forcing molten material through a die to create consistent shapes that can be cut to desired lengths.

door and window sealing strip factory

3. Quality Control Quality control is vital in the production of sealing strips. Manufacturers test their products for flexibility, durability, and temperature resistance to ensure they meet industry standards. This step ensures that the sealing strips can withstand varying environmental conditions while maintaining their effectiveness.

Innovations in Sealing Strip Technology

As technology advances, so does the manufacturing process of sealing strips. Modern factories are increasingly adopting automated systems that enhance efficiency and precision. Automated cutting and packaging processes reduce human error and ensure that every product meets the defined specifications.

Moreover, developments in materials science have led to innovative sealing solutions. For instance, self-adhesive strips and magnetic sealing systems have emerged, making installation faster and easier for consumers. These advancements not only improve usability but also enhance the overall effectiveness of sealing strips.

Environmental Impact

An essential aspect of the door and window sealing strip factory is its commitment to sustainability. Many modern factories are implementing green practices by sourcing raw materials responsibly and minimizing waste during the manufacturing process. Additionally, energy-efficient production methods are becoming commonplace, further reducing the environmental footprint.

Conclusion

A door and window sealing strip factory plays a vital role in enhancing energy efficiency and comfort in our living and working spaces. With the right combination of materials, advanced manufacturing techniques, and a strong commitment to quality and sustainability, these factories produce essential products that cater to the growing demand for energy-efficient solutions. As homeowners and businesses continue to seek ways to reduce energy consumption and improve indoor air quality, the importance of sealing strips will only increase, making these factories a critical component of the modern economy. By focusing on innovation and environmental responsibility, door and window sealing strip manufacturers are setting the stage for a more sustainable future.