Nov . 10, 2024 09:39 Back to list

Understanding D Type Rubber Fenders for Effective Marine Protection Solutions

Understanding D-Type Rubber Fenders

Rubber fenders play a crucial role in maritime operations, and among the various types available, D-type rubber fenders are one of the most popular choices due to their versatility and robustness. This article delves into the specifications, advantages, applications, and installation of D-type rubber fenders.

What Are D-Type Rubber Fenders?

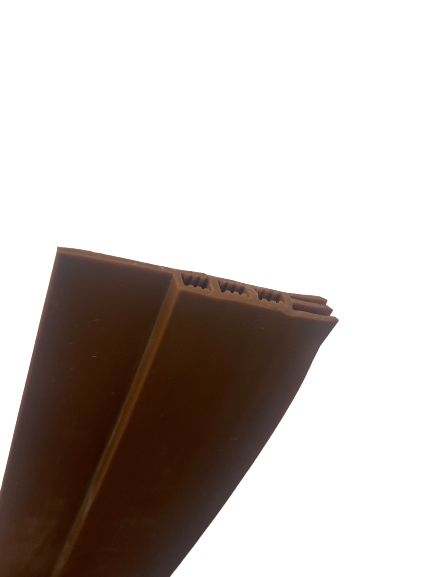

D-type rubber fenders are cylindrical fenders with a distinctive D-shaped cross-section. Constructed primarily from high-quality synthetic rubber, they are designed to absorb and dissipate the kinetic energy generated during the berthing process of vessels. The D-shape allows these fenders to effectively cushion the impact while providing high energy absorption and low reaction force, making them ideal for a variety of docking situations.

Key Specifications

D-type rubber fenders come in various sizes and configurations to meet specific maritime requirements. Common specifications include

- Length D-type fenders can range from a few feet to several meters, depending on the application and vessel size. - Diameter The diameter usually ranges from 300mm to 1,200mm, providing options for different levels of energy absorption. - Energy Absorption The capacity to absorb energy can vary significantly, depending on the size and design, allowing for adaptability across various vessel types, from small boats to large cargo ships.

Advantages of D-Type Rubber Fenders

1. Effective Energy Absorption D-type rubber fenders are designed to absorb impact energy, ensuring minimal damage to both the vessel and the docking structure. The unique shape enhances performance during berthing.

2. Durability Made from high-quality rubber compounds, these fenders are designed to withstand harsh marine environments, including seawater, UV exposure, and temperature variations, ensuring long service life.

3. Versatility With various sizes and configurations available, D-type fenders can be adapted for different docking scenarios, making them suitable for ports, piers, and shipyards.

d type rubber fender

4. Ease of Installation D-type rubber fenders are straightforward to install, typically mounted onto the marine structures using bolts or straps. Their design allows for easy alignment along the pilings or docks for optimal impact absorption.

5. Cost-Effectiveness Given their durability and low maintenance requirements, D-type rubber fenders offer a cost-effective solution for many ports and docking facilities.

Applications of D-Type Rubber Fenders

D-type rubber fenders are widely used across various maritime applications, including

- Ports and Harbors They are installed along docks and jetties to protect both the structure and vessels during mooring and unloading operations. - Shipyards In shipyards, D-type fenders provide crucial protection during the building and launching of new vessels, minimizing potential damage. - Offshore Platforms They are also employed in offshore structures to ensure stability and safety during supply vessel operations.

Installation Considerations

When installing D-type rubber fenders, several factors should be considered

1. Impact Forces Assess the expected impact forces based on vessel size and traffic to select the appropriate fender size and type. 2. Positioning The positioning of the fenders should be aligned with the vessel's mooring requirements to ensure optimal protection. 3. Maintenance Regular inspections should be conducted to ensure the fenders' integrity and performance. Any signs of wear or damage should be addressed promptly to extend their service life.

Conclusion

D-type rubber fenders are an essential component in the maritime industry, providing effective protection against impacts during berthing. Their advantageous features, such as robust energy absorption, durability, and versatility, make them a preferred choice for ports, shipyards, and offshore facilities. Proper installation and maintenance further enhance their usability and longevity, ensuring that vessels can dock safely and efficiently. As maritime operations continue to evolve, the reliance on effective solutions like D-type rubber fenders will undoubtedly remain significant in promoting safety and efficiency in marine environments.