Jul . 27, 2024 17:38 Back to list

Durable Anti-Collision Rubber Seals for Type D Ships for Enhanced Maritime Safety

Anti-Collision Rubber Seal for Ships Enhancing Safety and Durability

In the maritime industry, safety and durability are of paramount importance. Ships are constantly exposed to harsh environmental conditions and must endure various forms of physical contact, whether during docking, berthing, or navigating through crowded waters. One essential component that plays a critical role in protecting ships from damage is the anti-collision rubber seal, particularly the Type D products. These seals are designed to absorb impact force, prevent water ingress, and protect the vessel's structure, ensuring operational efficiency and safety.

Understanding Type D Anti-Collision Rubber Seals

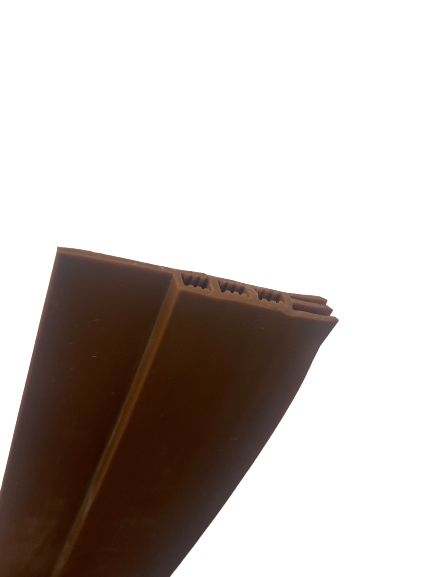

The Type D anti-collision rubber seal is specifically engineered to create a protective barrier around the perimeter of a ship. Made from high-quality rubber compounds, these seals exhibit excellent elasticity and resilience, allowing them to effectively dissipate the energy from impacts. Their design often includes a unique profile that conforms to the vessel’s hull while ensuring a snug fit against docking structures, such as piers and quays.

These seals are not only effective in mitigating damage during collisions but also play a vital role in maintaining the ship's integrity. The rubber material is resistant to corrosive marine environments, including saltwater exposure and UV radiation, which means that Type D seals can withstand the test of time. Regular maintenance and inspections of these seals can enhance their longevity and performance, translating to reduced operational costs for vessel operators.

Benefits of Using Anti-Collision Rubber Seals

1. Impact Absorption One of the primary functions of anti-collision rubber seals is to absorb shock during impacts. This reduces the likelihood of structural damage to the ship's hull and minimizes repair costs stemming from collisions, whether minor or severe.

anti-collision rubber seal for ship type d products

2. Water Ingress Prevention The seals form a tight barrier that helps prevent water from entering the ship during berthing or docking operations. This is crucial for maintaining buoyancy and stability, especially in adverse weather conditions.

3. Reduced Maintenance By protecting the ship’s hull from direct impacts and wear, anti-collision rubber seals contribute to lower maintenance needs. This allows operators to allocate resources more effectively, channeling funds that would otherwise go toward repairs into other areas of the business.

4. Customization Type D anti-collision seals can be tailored to meet specific needs based on the dimensions and design of a vessel. This adaptability allows shipbuilders and operators to develop specialized applications that cater to their unique requirements.

5. Environmental Resistance These seals are made from materials that can withstand harsh marine conditions, including temperature fluctuations, humidity, and abrasives. This durability ensures that the seals maintain their effectiveness over time, regardless of the operating conditions.

Conclusion

The implementation of Type D anti-collision rubber seals is an invaluable investment in ship safety and longevity. By mitigating impact forces and preventing water ingress, these seals enhance the overall operational efficiency of vessels, reduce repair costs, and contribute to safer maritime operations. As maritime activities continue to grow and evolve, the demand for reliable and robust protective solutions like anti-collision rubber seals will remain paramount. For ship operators, ensuring that their vessels are equipped with high-quality seals is not merely a choice but a necessity for safeguarding both the ship and its crew.