Aug . 19, 2024 18:13 Back to list

Durable Marine Sealing Solutions for Enhanced Protection and Longevity of Your Vessel

Understanding Marine Sealing Strips Importance and Applications

Marine sealing strips play an essential role in ensuring the integrity and longevity of various marine structures and vessels. These specialized sealing solutions are designed to withstand the harsh conditions commonly encountered in maritime environments, such as saltwater exposure, UV radiation, temperature fluctuations, and physical wear. This article delves into the importance of marine sealing strips, their applications, and the materials that make them effective.

What are Marine Sealing Strips?

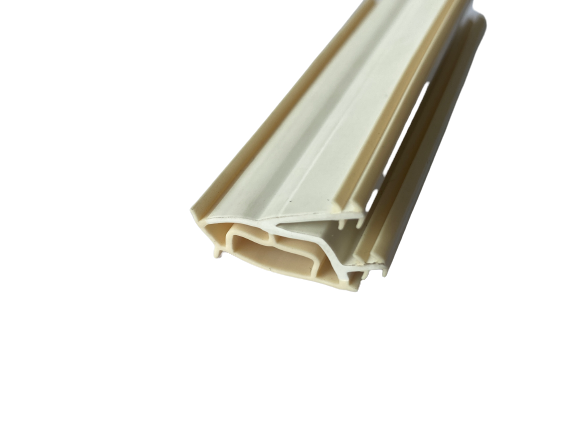

Marine sealing strips are flexible materials, often made from rubber, silicone, or thermoplastic elastomers, used to create a watertight and airtight seal in various marine applications. Their primary function is to prevent the intrusion of water, air, dirt, and other contaminants while allowing for movement and flexibility. This dual function is crucial, as vessels and marine structures often experience dynamic conditions, including waves, vibrations, and temperature variations.

Importance of Marine Sealing Strips

The significance of marine sealing strips cannot be overstated. In boating and shipping, maintaining a watertight seal is vital for the safety and performance of vessels. Water infiltration can lead to structural damage, equipment failure, and even catastrophic sinking. By utilizing high-quality marine sealing strips, vessel operators can significantly reduce the risk of leaks and enhance the overall safety of their operations.

Additionally, marine sealing strips help conserve energy. In many marine applications, such as HVAC systems within ships and offshore platforms, ensuring airtight seals can improve energy efficiency by minimizing energy losses. This not only results in cost savings but also contributes to environmental sustainability, a growing concern in the maritime industry.

Applications of Marine Sealing Strips

Marine sealing strips find utility across various applications, including

1. Boat Hulls Sealing strips are commonly used in the assembly of boat hulls to prevent water ingress. They ensure that the interfaces between different components are watertight.

marine sealing strip

2. Windows and Hatches Marine sealing strips are installed around windows and hatches to block water from entering the vessel. These seals are critical in maintaining visibility and operational functionality during rough conditions.

3. Doors The entry points on boats and marine structures require effective sealing to fend off water and maintain interior comfort. Marine sealing strips created from durable materials provide the necessary protection.

4. Decks and Bulkheads Sealing strips are used in the junctions of decks and bulkheads to create barriers against water intrusion, ensuring that water does not compromise vital structural elements.

5. Outdoor Equipment Marine equipment exposed to the elements often employs sealing strips for protection against corrosion and damage from environmental factors.

Materials Used in Marine Sealing Strips

The effectiveness of marine sealing strips largely depends on the materials used in their manufacture. Common materials include

- EPDM Rubber Known for its excellent resistance to ozone, UV radiation, and extreme temperatures, EPDM is a popular choice for outdoor applications. - Silicone Flexible and durable, silicone offers superior resistance to high temperatures and is often used in applications where a high degree of flexibility is needed. - PVC PVC sealing strips offer good chemical resistance and are often utilized in budget-friendly applications.

Conclusion

In conclusion, marine sealing strips are an indispensable component in the marine industry. Their ability to provide effective sealing while withstanding harsh environmental conditions makes them crucial for the safety and efficiency of vessels and marine structures. As technology advances and the demand for sustainable solutions grows, the development of more resilient and eco-friendly sealing materials will further enhance the performance of marine sealing strips, ensuring their continued importance in maritime applications for years to come.