Jul . 27, 2024 17:36 Back to list

Effective Solutions for Shipping Container Door Seals Made of Durable Rubber Materials

Understanding Shipping Container Door Rubber Seals Importance and Functionality

Shipping containers are essential components of global trade, facilitating the movement of goods across vast distances. Among the critical features that ensure their integrity and efficiency are the rubber seals employed on the doors. These seals are indispensable in maintaining the security and functionality of shipping containers, and their importance cannot be overstated.

What Are Shipping Container Door Rubber Seals?

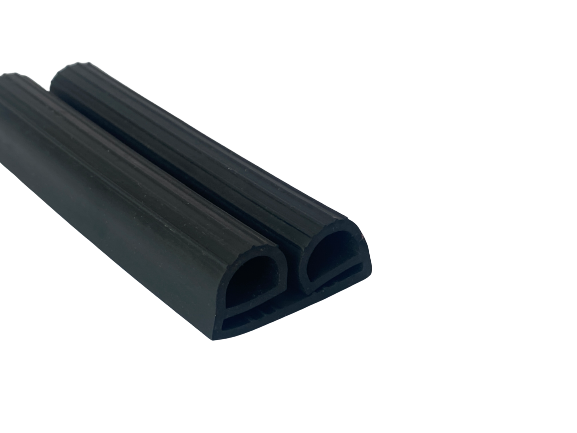

Shipping container door rubber seals, often referred to as door gaskets, are resilient strips of rubber designed to fit around the edges of container doors. They provide a sealing mechanism that prevents the entry of moisture, dust, and pests while also enhancing the structural integrity of the container. Typically made from materials like EPDM (ethylene propylene diene monomer) rubber, these seals are designed to withstand extreme weather conditions, UV exposure, and the rigors of oceanic transport.

Importance of Rubber Seals

1. Moisture Protection One of the primary functions of rubber seals is to prevent water from entering the container. Moisture can lead to mold growth, corrosion, and damage to goods, especially if they are sensitive to water, such as electronics, clothing, and food products. Rubber seals create a barrier that helps keep the interior of the container dry.

2. Pest Prevention Containers often travel through diverse environments, making them vulnerable to pests such as rodents and insects. A secure seal makes it difficult for pests to enter, safeguarding the cargo inside. This is particularly crucial for agricultural products, where contamination can have dire consequences.

shipping container door rubber seals

3. Temperature Regulation In many cases, shipping containers are used for temperature-sensitive goods. The rubber seals help maintain internal temperatures by minimizing heat exchange with the external environment. This is especially vital for food and pharmaceuticals, which often require specific conditions to remain viable.

4. Energy Efficiency Well-sealed containers contribute to energy efficiency as they reduce the amount of energy required to maintain regulated temperatures inside refrigerated containers. This, in turn, also has implications for environmental sustainability, as it reduces the carbon footprint associated with transporting goods.

Maintenance and Replacement

Just like any other component, the rubber seals on shipping container doors can wear out over time. Factors such as exposure to ultraviolet light, extreme temperatures, and mechanical stress can lead to degradation. Regular inspection of the seals is crucial, particularly before long journeys, to ensure they are intact and functional.

If damage or wear is detected, replacing the rubber seals promptly is essential. Replacement is typically straightforward and can be done without specialized equipment. High-quality replacement seals are available from various manufacturers, and choosing the right type is vital to match the specific design of the container doors.

Conclusion

In summary, shipping container door rubber seals play a crucial role in the overall effectiveness and reliability of shipping containers. They provide essential protection against moisture, pests, and temperature fluctuations, which are vital for preserving the quality of goods during transit. Regular maintenance and timely replacement of these seals can significantly enhance the longevity and performance of shipping containers, ensuring that they serve their purpose in global commerce efficiently. As international shipping continues to grow, understanding the importance of such components is critical for businesses looking to protect their investments in logistics and supply chain management.