Aug . 18, 2024 04:13 Back to list

EPDM Gaskets for Oil Tanks from Leading Exporters Worldwide

The Role of EPDM Rubber in Oil Tank Gaskets An Overview for Exporters

EPDM (Ethylene Propylene Diene Monomer) rubber is a highly versatile synthetic rubber commonly used in various applications, including automotive components, roofing membranes, and industrial seals. One of its critical applications is in the production of gaskets for oil tanks. For exporters looking to venture into the EPDM oil tank gasket market, understanding the properties, advantages, and market demands of this material is essential for success.

Properties of EPDM Rubber

EPDM rubber is known for its impressive resistance to weathering, ultraviolet light, and ozone degradation, making it an ideal choice for outdoor and industrial applications. It offers excellent chemical resistance, particularly to polar solvents and water, which is crucial for oil tank gaskets that must maintain integrity against various hydrocarbon fluids.

Another important characteristic of EPDM is its elasticity and flexibility, even under extreme temperatures. This property ensures a tight seal that can withstand fluctuations in temperature and pressure, preventing leaks and contamination—critical factors for oil storage facilities to ensure safety and compliance with environmental regulations.

Advantages of EPDM Oil Tank Gaskets

1. Durability EPDM gaskets have a long lifespan owing to their resistance to wear and tear. This durability means that oil tanks can operate without frequent gasket replacements, reducing maintenance costs.

3. Temperature Tolerance EPDM maintains its performance characteristics in both high and low-temperature environments, making it suitable for various geographic locations and climates.

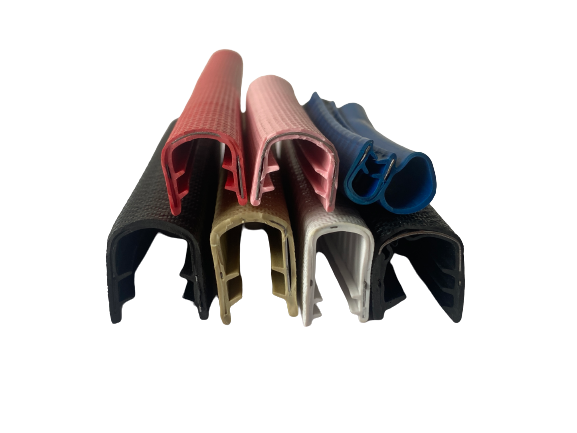

4. Customizability EPDM can be manufactured in various shapes, sizes, and thicknesses. This flexibility allows exporters to cater to specific customer requirements and unique specifications of different oil tank designs.

epdm oil tank gasket exporter

5. Eco-Friendly Options As environmental awareness grows, many industries are seeking sustainable materials. EPDM can be produced using recycled materials, providing a greener alternative for oil tank gaskets.

Market Demand and Export Potential

The global oil and gas industry continues to grow, driven by demand for energy. This growth fuels the need for efficient storage solutions, including high-quality gaskets for oil tanks. Exporters can capitalize on this demand by ensuring they provide high-quality EPDM gaskets that meet international standards.

Regions such as North America, Europe, and parts of Asia are seeing increasing investments in oil infrastructure, further driving the need for dependable sealing solutions. Additionally, countries undergoing rapid industrialization may present new opportunities for gasket exports, as they develop their oil storage capabilities.

Challenges in Exporting EPDM Oil Tank Gaskets

While there is significant potential in this market, exporters must navigate several challenges. Regulatory compliance varies by region, and understanding the certifications needed for different markets is crucial. Quality control is another critical aspect; maintaining high production standards is essential to avoid costly recalls and damage to brand reputation.

Moreover, competition can be fierce, with many manufacturers producing similar products. Therefore, exporters must differentiate themselves through superior product quality, responsive customer service, and effective distribution strategies.

Conclusion

The export of EPDM oil tank gaskets presents a profitable opportunity for businesses willing to navigate the complexities of the global marketplace. By focusing on the unique properties and advantages of EPDM, and understanding market needs and challenges, exporters can effectively position themselves in this growing segment. With proper planning and execution, the future looks promising for those in the EPDM gasket export industry.