Dec . 14, 2024 20:24 Back to list

EPDM Sealing Solutions for Automotive Fuel Tank Gaskets and Manufacturers

The Role of EPDM in Automotive Fuel Tank Gaskets Key Considerations for Manufacturers

In the automotive industry, the integrity of components that come into contact with fuel is paramount. One of the critical elements in ensuring fuel tanks operate optimally is the gasket. Among the materials used for automotive fuel tank gaskets, Ethylene Propylene Diene Monomer (EPDM) has emerged as a leading choice for manufacturers. This article delves into the properties of EPDM, its advantages, applications, and considerations for manufacturers in producing high-quality fuel tank gaskets.

Understanding EPDM

EPDM is a synthetic rubber that is known for its outstanding resistance to heat, oxidation, and ozone. This polymer is created through the polymerization of ethylene, propylene, and a diene component, which offers a versatile set of properties that make it suitable for a wide range of applications. In the automotive sector, EPDM is widely used in seals and gaskets because of its durability and performance under varying environmental conditions.

Key Properties of EPDM

1. Chemical Resistance EPDM exhibits excellent resistance to a wide range of chemicals, including fuels, oils, and solvents. This property is crucial for fuel tank gaskets, which are constantly exposed to various hydrocarbons that can degrade other materials.

2. Weather Resistance The automotive environment is subject to extreme weather conditions, from high temperatures to freezing cold. EPDM's superior weather resistance ensures that gaskets maintain their integrity over time, preventing leaks and ensuring safety.

3. Durability and Longevity EPDM gaskets have a long service life, reducing the need for frequent replacements. This durability not only benefits manufacturers by minimizing production costs but also enhances the safety and reliability of vehicles.

4. Temperature Tolerance EPDM can function well across a wide temperature range, often from -50°C to 150°C (-58°F to 302°F). This flexibility makes it suitable for varied climates, ensuring that fuel tank gaskets perform consistently in diverse conditions.

Advantages of EPDM for Fuel Tank Gasket Manufacturing

For automotive manufacturers, choosing EPDM for fuel tank gaskets presents several advantages

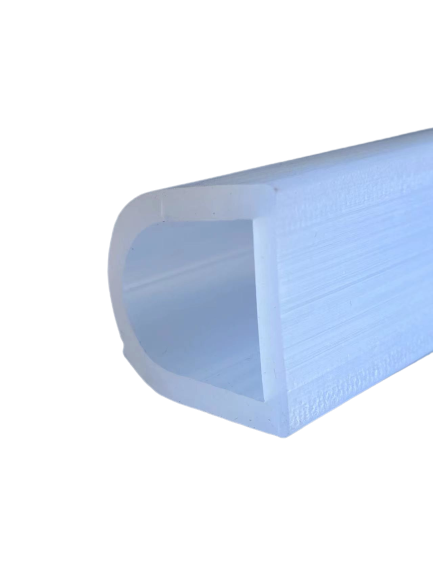

epdm automotive fuel tank gasket manufacturer

- Cost-Effectiveness While EPDM is a high-performance material, its production cost is relatively low compared to other synthetic rubbers. This balance of cost and performance makes it an economical choice for mass production.

- Ease of Fabrication EPDM can be easily molded and extruded, allowing manufacturers to create complex gasket shapes and sizes that fit various vehicle models. This adaptability is a significant advantage in an industry focused on customization.

- Environmental Compliance As the automotive sector shifts toward sustainable practices, using EPDM—a recyclable material—supports manufacturers' commitments to reducing their environmental footprint.

Challenges and Considerations

While EPDM offers numerous benefits, manufacturers must also consider certain challenges

- Adhesion Issues One of the potential drawbacks of EPDM is its compatibility with adhesives. Manufacturers need to select appropriate bonding agents to ensure effective sealing without compromising material performance.

- Aging Effects Over time, EPDM may experience some degradation, particularly when subjected to constant exposure to fuel and intense heat. It is essential for manufacturers to test materials rigorously to ensure long-term performance.

Future Trends

As the automotive industry evolves towards electric vehicles (EVs) and alternative fuels, the demand for innovative gasket materials, including EPDM, will likely grow. Manufacturers must stay ahead of the curve by researching and developing new formulations of EPDM that can withstand the unique challenges posed by these emerging technologies.

Conclusion

EPDM has established itself as a critical material in the production of automotive fuel tank gaskets. Its unique properties provide robust solutions to the demanding requirements of the automotive industry. As manufacturers continue to innovate and adapt to new challenges, EPDM remains a reliable choice for ensuring vehicle performance, safety, and longevity. In a world where quality and reliability are of utmost concern, investing in high-quality EPDM gaskets reflects a commitment to excellence in automotive manufacturing.