Oct . 16, 2024 12:24 Back to list

epdm automotive fuel tank gasket products

The Importance of EPDM Automotive Fuel Tank Gasket Products

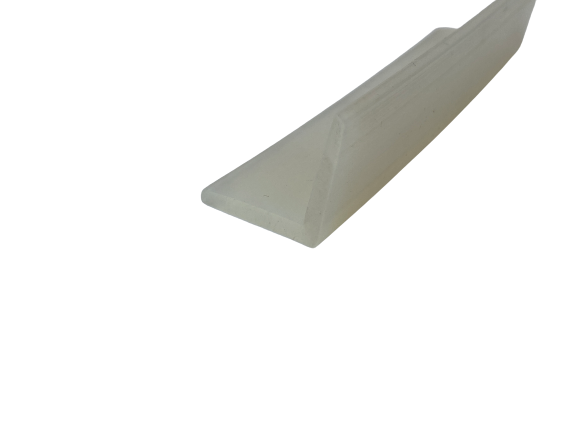

In the automotive industry, the reliability and safety of vehicles are of utmost importance. One crucial component that plays a significant role in maintaining the integrity of fuel systems is the gasket. Among various materials used in manufacturing automotive gaskets, Ethylene Propylene Diene Monomer (EPDM) has emerged as a popular choice, particularly for fuel tank applications. This article explores the benefits and applications of EPDM automotive fuel tank gasket products.

EPDM is a synthetic rubber known for its excellent resistance to heat, ozone, and aging. These properties make it highly suitable for automotive applications where exposure to harsh environments is inevitable. In fuel tank systems, gaskets made from EPDM provide a reliable seal that prevents fuel leakage, ensuring that the vehicle operates efficiently and safely. The durability of EPDM gaskets also aids in reducing maintenance costs, as they are less likely to degrade or fail compared to traditional materials.

One of the primary advantages of EPDM gaskets is their ability to withstand a wide temperature range, from extreme cold to high heat. This characteristic is particularly important for vehicles that operate in various climates and conditions. EPDM remains flexible and effective even in low-temperature scenarios, ensuring that a tight seal is maintained under all circumstances. This flexibility also makes installation easier, as the gaskets can easily conform to the unique shapes of automotive fuel tanks.

epdm automotive fuel tank gasket products

In addition to temperature resistance, EPDM gaskets are chemically stable, making them less susceptible to the effects of different fuels and additives. This is vital in modern automotive applications, where fuels may contain a variety of chemicals that can degrade less-resistant materials. The compatibility of EPDM with gasoline, diesel, and biofuels ensures that it remains a viable choice for manufacturers focused on producing long-lasting and effective fuel tank components.

Furthermore, the use of EPDM gaskets contributes to environmental sustainability. As the automotive industry increasingly shifts towards eco-friendly practices, using durable materials helps reduce waste. EPDM’s longevity means that gaskets need to be replaced less frequently, minimizing the overall environmental impact. Additionally, many EPDM products are recyclable, aligning with the industry’s goals of decreasing plastic waste.

Manufacturers are also leveraging advanced production techniques to enhance the performance of EPDM fuel tank gaskets. Innovations such as reinforced structures and optimized designs are being integrated to improve sealing capabilities and extend the lifespan of these components. This focus on research and development ensures that automotive fuel tank gaskets continue to evolve, meeting the changing demands of the automotive market.

In conclusion, EPDM automotive fuel tank gasket products offer numerous advantages, including superior chemical resistance, temperature resilience, and environmental sustainability. With the increasing complexity of fuel systems in modern vehicles, the reliability of these gaskets becomes paramount. Manufacturers must prioritize the use of high-quality materials like EPDM to ensure efficiency and safety in automotive fuel systems. As automotive technology evolves, EPDM gaskets will remain a vital component in delivering performance and reliability in the automotive industry.