Nov . 05, 2024 11:43 Back to list

epdm rubber sheet products

Understanding EPDM Rubber Sheet Products Features and Applications

EPDM (Ethylene Propylene Diene Monomer) rubber is a type of synthetic rubber that boasts exceptional performance characteristics and durability. Due to its outstanding properties, EPDM rubber sheets are increasingly being used in a wide variety of industrial, commercial, and residential applications. This article explores the features, benefits, and uses of EPDM rubber sheet products.

Key Features of EPDM Rubber Sheets

1. Weather Resistance One of the most noteworthy characteristics of EPDM rubber is its exceptional resistance to environmental factors. EPDM sheets are highly resistant to UV radiation, ozone, and harsh weather conditions. This makes them ideal for outdoor applications where prolonged exposure to sunlight and extreme weather can degrade other materials.

2. Temperature Tolerance EPDM rubber can perform effectively across a wide range of temperatures, typically from -40°F to 250°F. This versatility allows it to be used in both cold and hot environments without losing its structural integrity or flexibility.

3. Chemical Resistance EPDM rubber is resistant to a wide variety of chemicals, including acids, alkalis, and water. This make it a suitable choice for applications in chemical processing, automotive, and construction industries.

4. Electrical Insulation EPDM provides excellent electrical insulation properties, which allows it to be used in various electrical applications, including cable insulations and protective coatings.

5. Durability and Longevity EPDM rubber sheets are known for their durability. They have a long service life, reducing the need for frequent replacements and maintenance.

epdm rubber sheet products

Applications of EPDM Rubber Sheets

1. Roofing EPDM rubber is widely used in roofing systems for commercial and residential buildings. Its waterproof properties make it an excellent choice for flat roofs, and it can be easily adhered to various substrates for effective sealing.

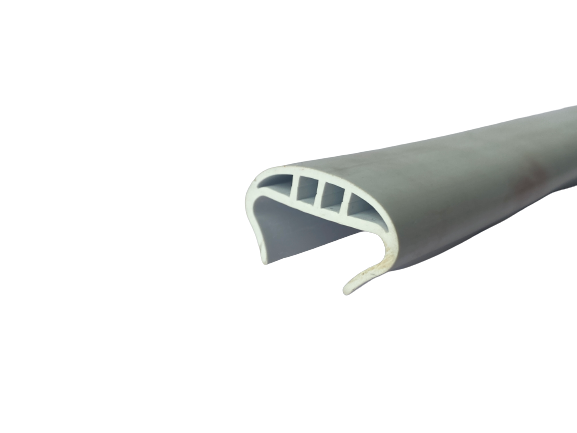

2. Gaskets and Seals Due to its flexibility and resilience, EPDM rubber is often used to manufacture gaskets and seals. These components provide reliable sealing solutions in plumbing and automotive applications, helping to prevent leaks and maintain pressure.

3. Automotive EPDM rubber is a popular material for various automotive parts, including weather-stripping, seals, and hoses. Its ability to withstand harsh conditions and chemicals ensures that components remain functional and reliable over time.

4. Industrial Applications EPDM sheets are also utilized in various industrial settings. They can be found in equipment lining, vibration dampening, and as protective coverings, particularly in machinery that operates under extreme conditions.

5. Playground Surfaces Another emerging application of EPDM rubber is in playground safety surfaces. When used as flooring, EPDM provides a cushioned surface that helps in preventing injuries during play.

In conclusion, EPDM rubber sheet products offer an array of features that contribute to their usefulness in countless applications. Their resistance to weather, chemicals, temperature extremes, and their overall durability make them a preferred choice for many industries. Whether used in roofing, automotive parts, or playground surfaces, EPDM rubber continues to demonstrate its value and versatility in the modern world.

Next:

Prev: